Valve fatigue-life testing device

A testing device and fatigue life technology, applied in the direction of heart valve, etc., can solve problems such as difficulty in adjusting the pressure waveform, and achieve the effect of simple adjustment of the pressure waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

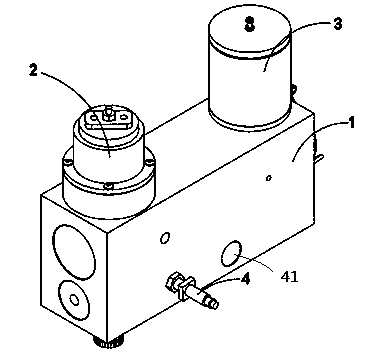

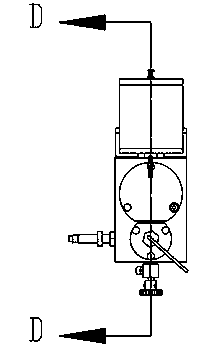

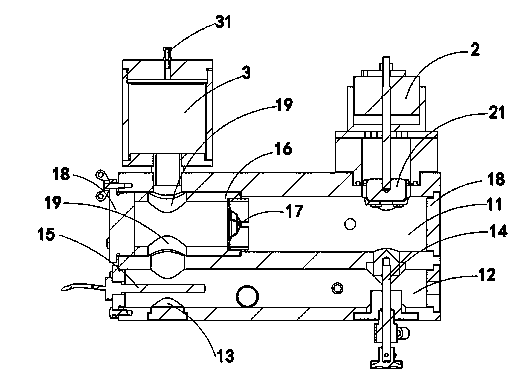

[0023] The present invention discloses a valve fatigue life testing device, and the present invention will be further described below in conjunction with an artificial heart valve. Such as Figure 1 to Figure 3 As shown, at least one module assembly is included, and the module assembly includes a body 1 . An opening 13 is provided on the bottom side of the body 1, and an outlet valve 41 is provided on the side of the body for releasing the test liquid in the device. A linear motor 2 is mounted on one side of the top of the body, and a piston 21 with a rolling diaphragm is connected to the shaft of the linear motor 2 , and the piston 21 is inserted into the body 1 .

[0024] The other side of the top of the body 1 is provided with a liquid container 3, the liquid container 3 communicates with the body 1, and the top of the liquid container 3 is provided with an open cover 31;

[0025] The interior of the body 1 is mainly composed of upper and lower flow passages that communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com