A fully automatic jerky slicer and slicing machine

An all-in-one, fully automatic technology, applied in metal processing and other directions, can solve the problems of inconsistent product specifications, affecting product color, low work efficiency, etc., to achieve automatic control, good use effect, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

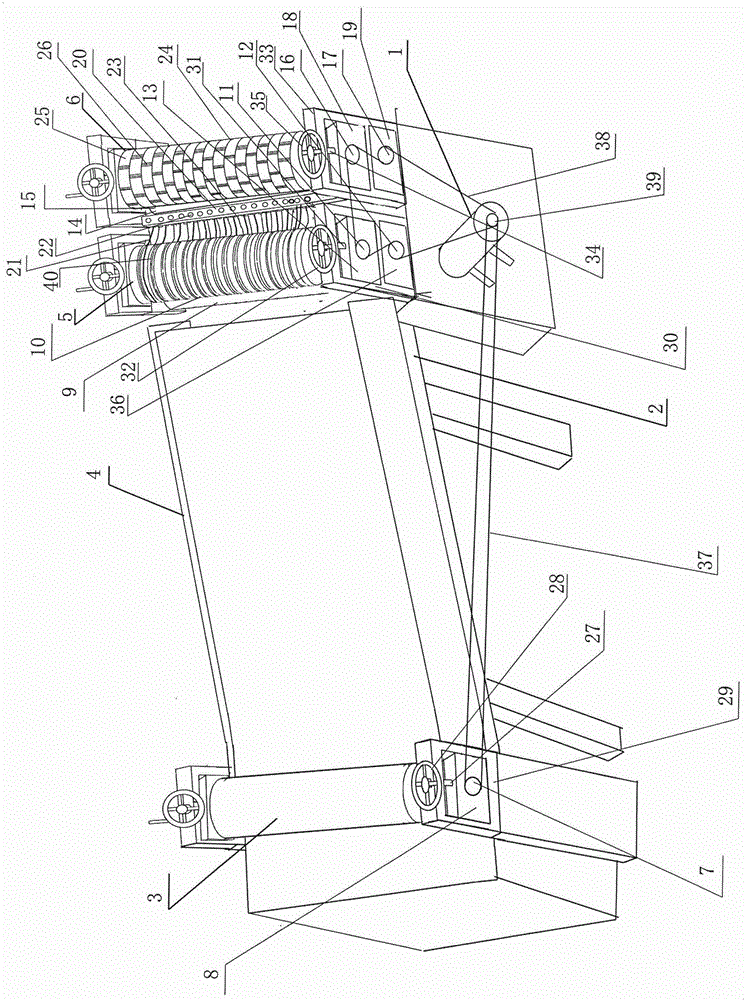

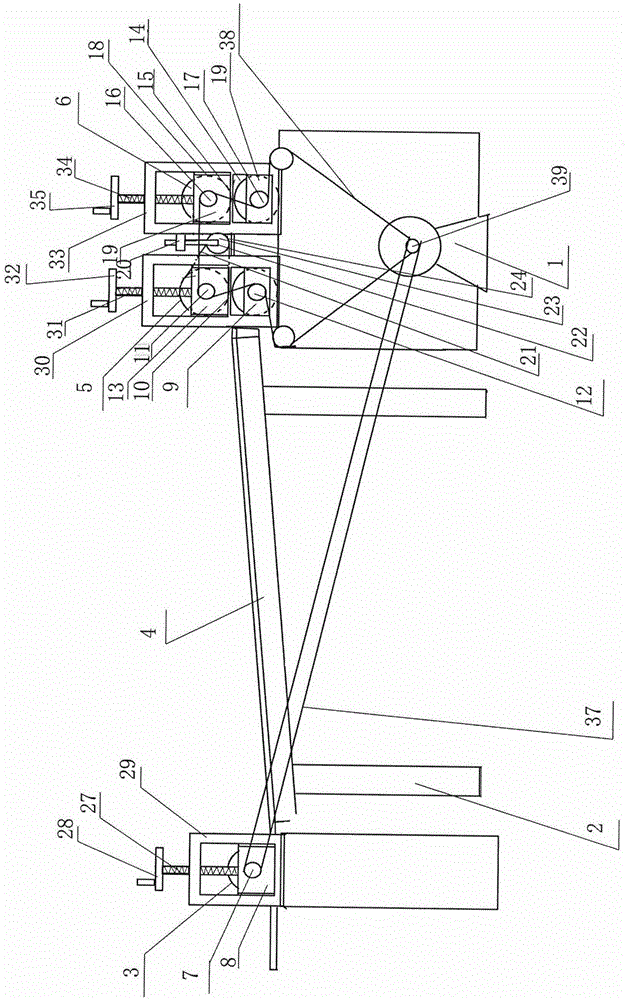

[0010] exist figure 1 with figure 2Among them, the present invention provides a fully automatic jerky slicer and slicing integrated machine, which is characterized in that it includes a motor 1, a transmission device and a frame 2, and the frame is provided with feeding rollers 3 from the beginning to the end. , conveying device 4, longitudinal cutter cylinder 5 and transverse cutter cylinder 6, between the described longitudinal cutter cylinder 5 and the transverse cutter cylinder 6, a partition guide frame is fixedly arranged, and the axis of the feed pressure roller 3 There is a rotating shaft I7 to the center, and a lifting platform I is respectively provided on both sides of the feeding pressure roller 3, and the feeding pressing roller 3 is respectively connected with the lifting seats I8 of the two lifting platforms I through the two ends of the rotating shaft I7, and the feeding pressure roller 3 can move up and down with the lifting seat Ⅰ8, and the feeding pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com