Automatic cutting and arranging punch

An automatic and punching technology, applied in metal processing, etc., can solve the problems of secondary pollution, large manpower and material resources, unfavorable product processing punching efficiency, etc., to achieve the effect of improving production efficiency and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

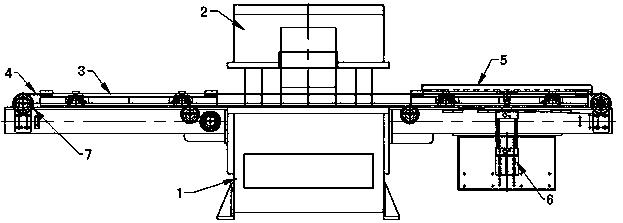

[0012] Assuming that the punched product is a PP food box, see figure 1 As shown in the figure, the automatic cutting and finishing punch mainly includes a cutting machine 2, a synchronous belt 4, a knife template 3, and a product self-stacking frame 5; a synchronous belt 4 is provided on the frame 1, and the synchronous belt 4 is driven by the synchronous pulley 7, located in the synchronous A cutting machine 2 is installed in the middle of the belt 4, and a mandrel 6 is installed at the end of the synchronous belt 4. The upper end of the mandrel 6 is correspondingly provided with a product self-stacking frame 5 that can be repeatedly taken out and loaded, and the product is hedged from the stacking frame 5. The cut products are collected, the ejector rod 6 is driven by a cylinder, the synchronous pulley 7 is driven by a motor, and the ejector rod 6 and the sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com