Cast sheet forming cooling device and cooling method for film production line

A cooling device and production line technology, applied in the field of casting sheet cooling device, can solve the problems of the cooling effect not meeting the requirements, the influence of the thick sheet forming quality, the unqualified product quality, etc., achieving good apparent quality, improving the cooling forming quality, The effect of uniform cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

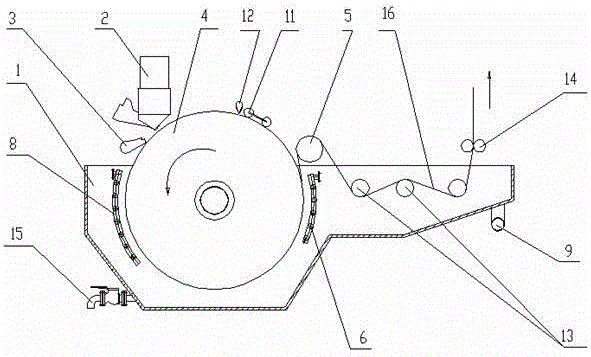

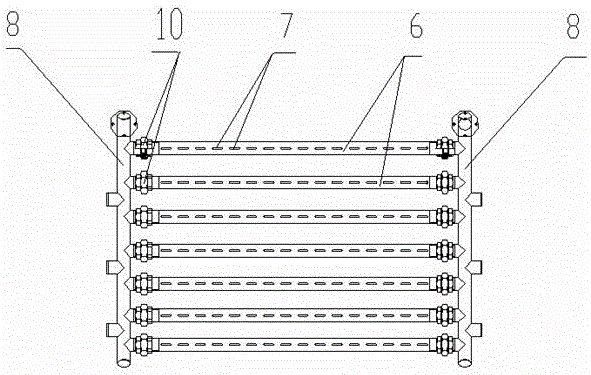

[0035] Such as figure 1 , figure 2 As shown, the cast sheet forming cooling device of the film production line includes a water tank 1, a die head 2, a sheet attachment device 3, a stripping roller device 5 and a chill roll 4 installed in the water tank 1; the die head 2, the stripping roll The device 5 is respectively installed on the upper side of both sides of the chilling roller 4, above the water tank 1, and the sheet attachment device 3 is installed between the die head 2 and the chilling roller 4; The cold water flow channel arranged in the circumferential direction of the roller body; the left and right sides of the chilled roller 4 are equipped with water spray pipes 6, 7 groups are installed on the left side, and 5 groups are installed on the right side, and the water spray pipes 6 It is a straight pipe, arranged in the water tank 1, the axial direction of the water spray pipe 6 is parallel to the axial direction of the chilling roller, and the side of the water sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com