Granular composite grease lubricating material bead blasting tower

A technology of lubricating material and compound grease, applied in the field of compound grease lubricating material production equipment, can solve problems such as unfavorable transportation and weighing of compound grease lubricating material, and achieve the effects of improving the quality of cooling and forming, facilitating transportation and weighing, and having a reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

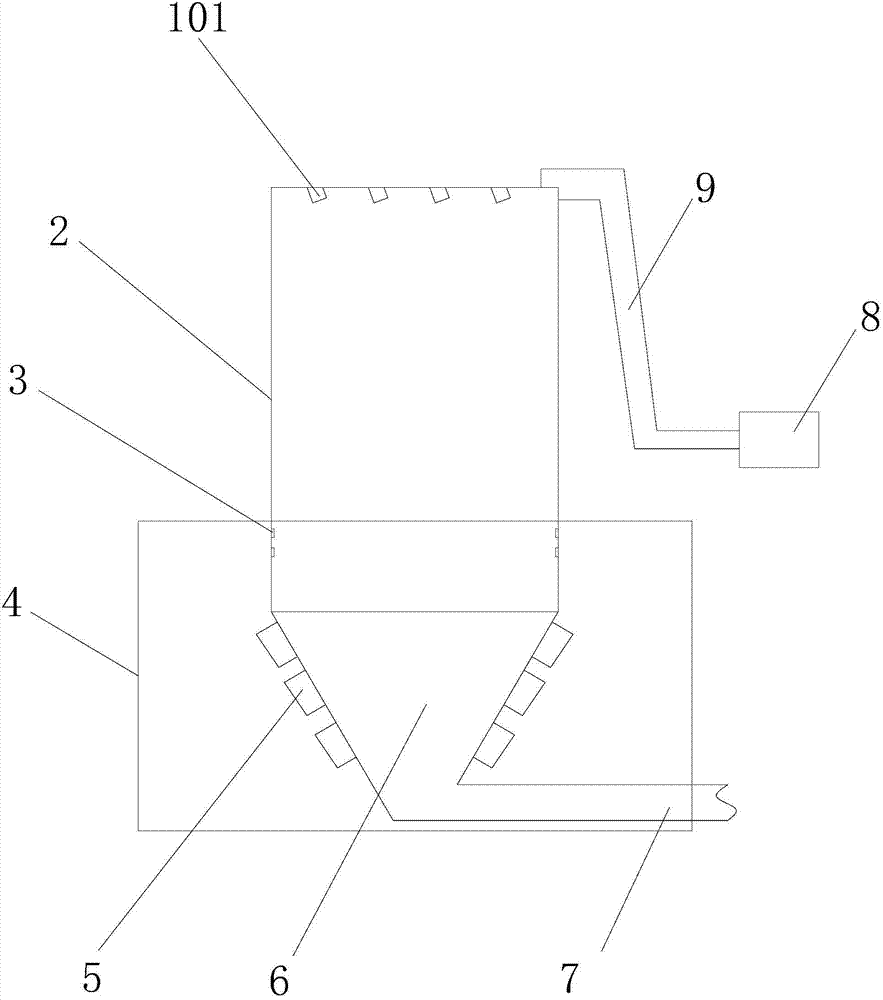

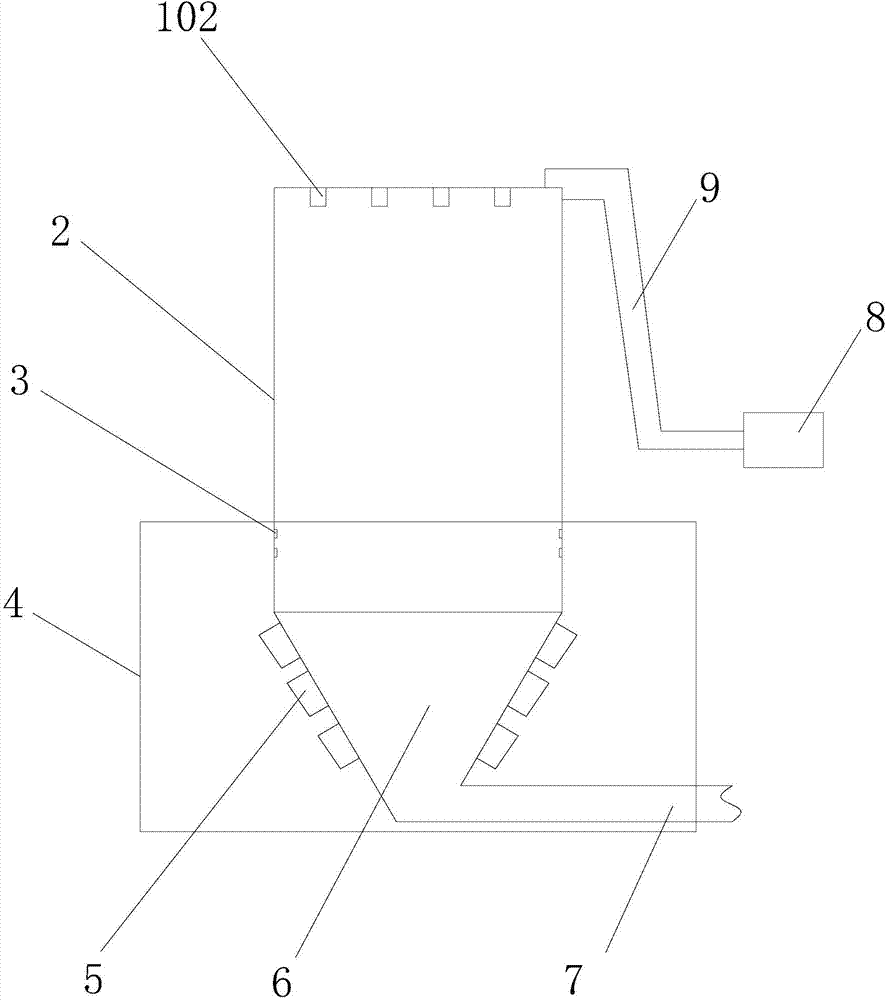

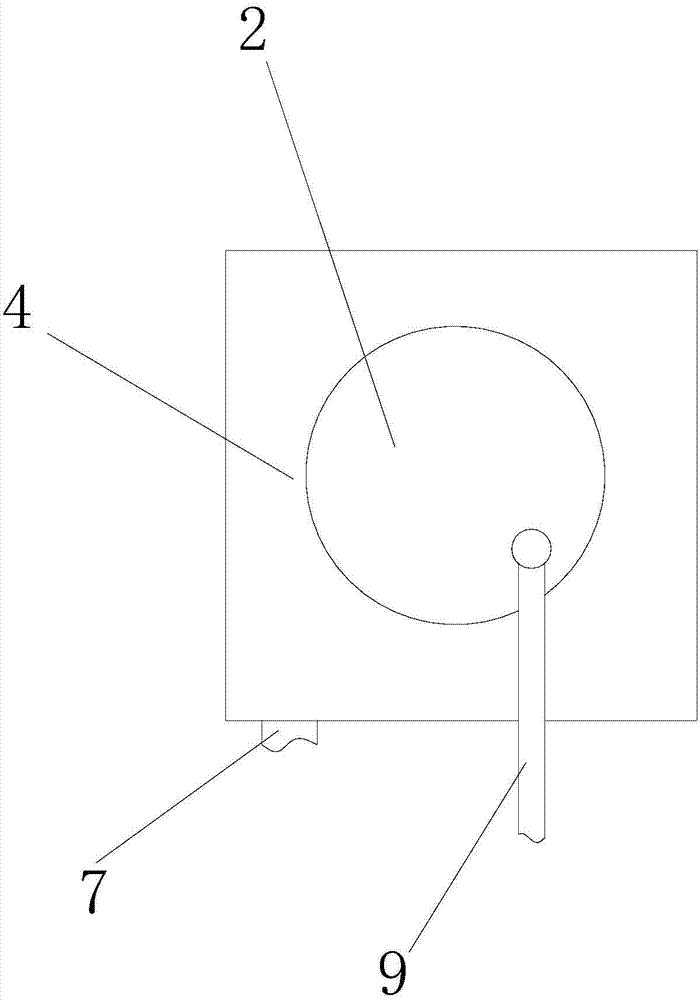

[0026] Such as figure 1 , figure 2 As shown, a granular compound grease lubricating material spray tower includes a tower body and a tower base 4 . The tower body includes a tower body 2 and a collection device 6 connected to the lower end of the tower body 2 . A sprinkler device is arranged on the inner top surface of the tower body 2 , a hot air collecting device is arranged on the upper part of the tower body 2 , and a natural cooling device is arranged on the lower part of the tower body 2 . The lower part of the tower body is provided with a cooling device. The lower end of the collecting device extends into the tower base.

[0027] In this embodiment, the tower base 4 is a base of a square brick structure. A safety door is respectively arranged on the four sides of the tower base 4 .

[0028] The spray head device includes at least two spray heads arranged on the inner top surface of the tower body, the at least two spray heads are on the same circumferential line,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com