Glued release cloth and manufacturing method thereof

A production method and release cloth technology are applied to chemical instruments and methods, cellulose plastic material layered products, lamination devices, etc., which can solve the problems of heavy release cloth, high production cost, and non-compliance, and achieve Simple processing, low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

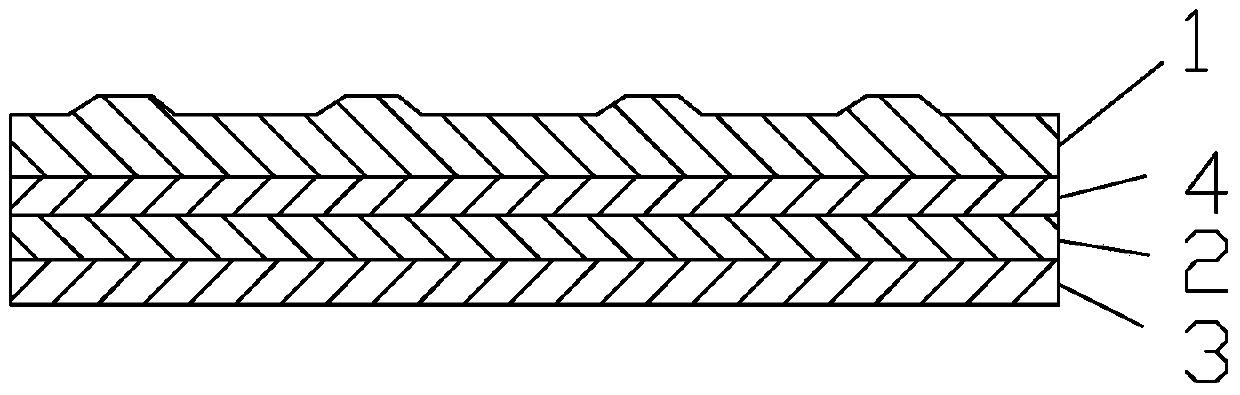

[0016] refer to figure 1 , a glued release fabric provided by the present invention comprises a non-woven fabric 1, a casting plastic film 2 and a silicone oil layer 3 from top to bottom, and heat is applied between the non-woven fabric 1 and the casting plastic film 2. Melt glue 4 is used for bonding. In this embodiment, three-dimensional lines are printed on the upper surface of the release cloth, and the three-dimensional lines are printed on the non-woven fabric 1. The three-dimensional line patterns have a stronger texture and a more beautiful appearance, and are more attractive than ink printing patterns. Cost saving, better environmental protection effect.

[0017] As a preferred embodiment, the silicone oil layer 3 is UV silicone oil, solvent silicone oil or solvent-free silicone oil, which have the same technical effect and are equivalent technical solutions. Further, the quality of the release cloth is 15-50 g / m2, the overall weight is low, and raw materials are sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com