Preparation technology of colored glaze encaustic

A preparation process and porcelain painting technology, which is applied in decorative arts, special decorative structures, etc., can solve the problems of rough lines and contours of the picture, poor image quality, and low fidelity of porcelain paintings, so as to facilitate industrial production and maintain fidelity. High-resolution, realistic picture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

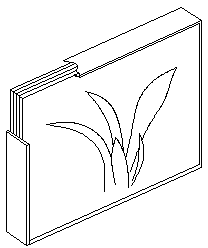

Image

Examples

specific Embodiment approach

[0014] The specific embodiment of the present invention is described below: a kind of preparation technology of colored glaze porcelain painting, after spraying a layer of transparent glaze on the ceramic substrate and drying, directly on the transparent glaze with the pigment that is pulverized to the nanoscale spray-painting pattern, after that A layer of transparent glaze is sprayed on the top of the pattern, and finally it is fired in a kiln to make the pigment penetrate into the transparent glaze, and then the finished product is obtained after cooling.

[0015] Adding a transparent glaze layer outside the transparent glaze layer soaked with the glaze painting layer can further enhance the preservation resistance of the porcelain painting, so that the pigment is completely isolated from the outside air, which is more conducive to the long-term preservation of the porcelain painting.

[0016] There is also a layer of flexible buffer layer on the back of the substrate. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com