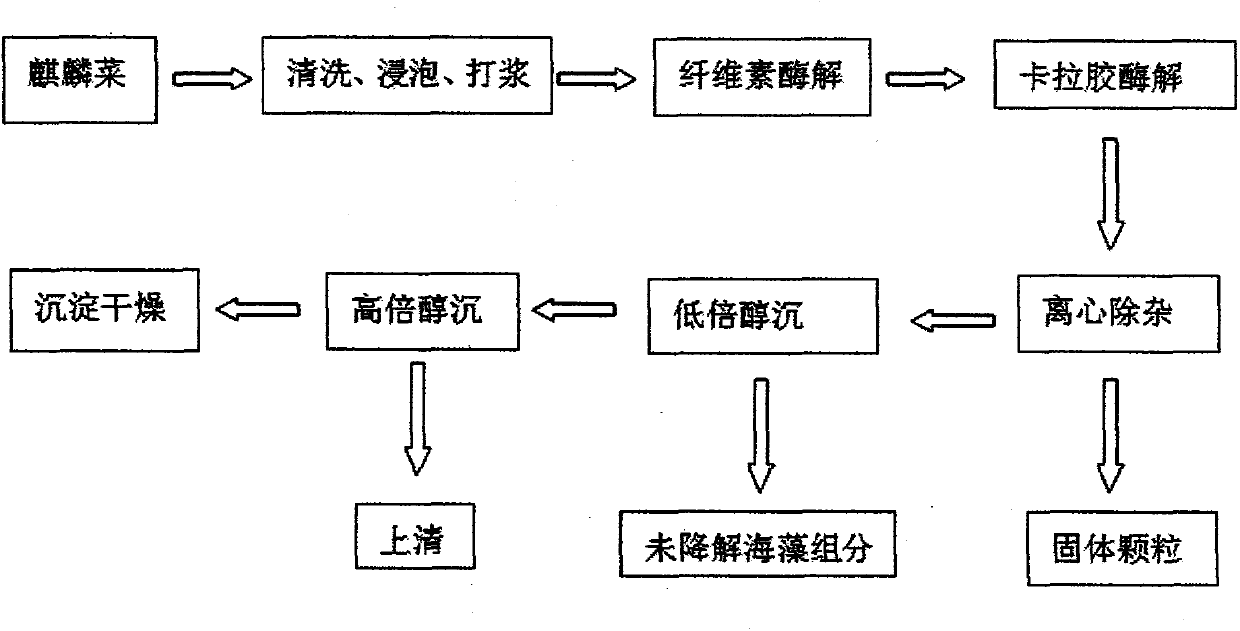

Method for preparing carrageenin oligosaccharides by compositely degrading eucheuma with carrageenanase and cellulase

A technology of carrageenan oligosaccharides and cellulase, which is applied in fermentation and other directions, and can solve problems such as consumption, large energy resources, and uneven distribution of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Wash and soak 20g of dried Eucheuma, the weight after rehydration is about 200g, add water and homogenate to a final volume of 600mL.

[0019] 2. Adjust the homogenate to pH 5.0, add cellulase according to the amount of 21,000 U / g dry Eucheuma, and shake and react at 50°C for 2.5h.

[0020] 3. Cool the reaction liquid to about 35°C, add carrageenase according to the amount of 5 U / g dry Eucheuma, and shake the reaction at 35°C for 8 hours. Boil the enzymolysis solution to kill the enzyme, then centrifuge at 5000rpm for 10min to remove solid particles such as seaweed residue.

[0021] 4. Concentrate the supernatant to 300mL by rotary evaporation, stir and add 300mL ethanol, and centrifuge at 8000rpm for 15min to remove the undegraded seaweed components.

[0022] 5. Concentrate by rotary evaporation again to 50mL, add 250mL ethanol, at this time, a large amount of white sugar precipitates appear. Centrifuge at 5000rpm for 10min to obtain a large amount of white precip...

Embodiment 2

[0025] 1. Wash and soak 5g of dried Eucheuma, the weight after rehydration is about 40g, add water and homogenate to a final volume of 200mL.

[0026] 2. Adjust the homogenate to pH 5.0, add cellulase according to the amount of 18,000 U / g dry Eucheuma, and shake at 50°C for 2 hours.

[0027] 3. Cool the reaction liquid to about 35°C, add carrageenase according to the amount of 5 U / g dry Eucheuma, and shake the reaction at 35°C for 12 hours.

[0028] 4. Centrifuge the enzymatic solution at 5000 rpm for 10 minutes to remove solid particles such as seaweed residue.

[0029] 5. Concentrate the supernatant to 100mL by rotary evaporation, add 100mL ethanol after stirring, and centrifuge at 8000rpm for 15min to remove undegraded seaweed components.

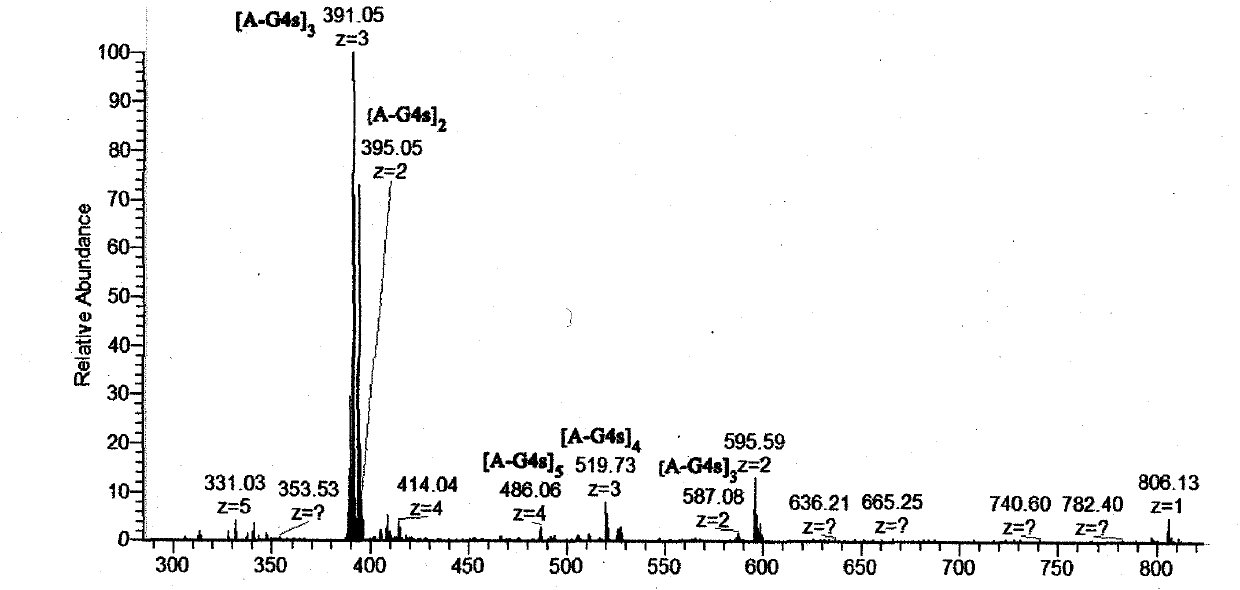

[0030] 6. Concentrate the supernatant to 20mL by rotary steaming, add 100mL ethanol to precipitate and collect carrageenan oligosaccharides, and dry them to obtain tetrasaccharides, hexasaccharides, octasaccharides, decasaccharides, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com