Textile rubber ring

An apron and ring body technology, applied in textiles and papermaking, spinning machines, drafting equipment, etc., can solve the problems of destroying drafting distribution in the drafting area, being difficult to resist external forces, and sliver deterioration, etc., and achieving long service life. , Simple structure, uniform thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

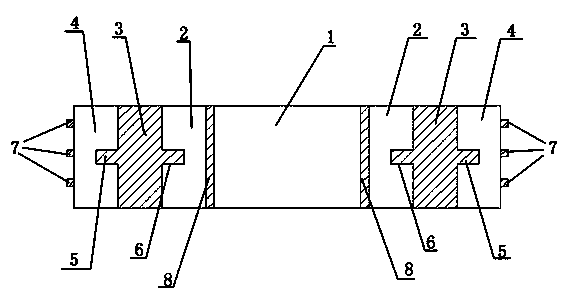

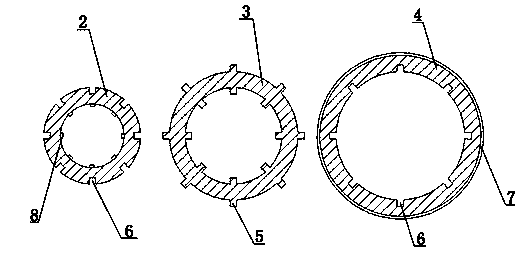

[0015] Such as figure 1 with figure 2 As shown, a kind of textile apron of the present invention comprises a ring body 1, and the ring body 1 includes an inner rubber layer 2, a reinforced layer 3 and an outer rubber layer 4, and a circle of cylindrical protrusions 5 are respectively arranged on both sides of the reinforced layer 3, The side of the inner rubber layer 2 and the outer rubber layer 4 corresponding to the reinforcement layer 3 is provided with a circle of cylindrical grooves 6, and the protrusions 5 and the grooves 6 are correspondingly arranged; the outside of the outer rubber layer 4 is provided with three circles of equidistantly arranged reinforcing ribs 7. The reinforcing rib 7 is bonded to the outer rubber layer 4. The inner side of the inner rubber layer 2 includes a circle of vertical striped protrusions 8 equidistantly arranged. The ring body is made of nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com