Blowdown device of closestool

A sewage discharge device and toilet technology, applied to water supply devices, flushing equipment with water tanks, sanitary equipment for toilets, etc., can solve the problems of paper shredders with low sewage discharge capacity, etc., and achieve the effect of reducing water consumption and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

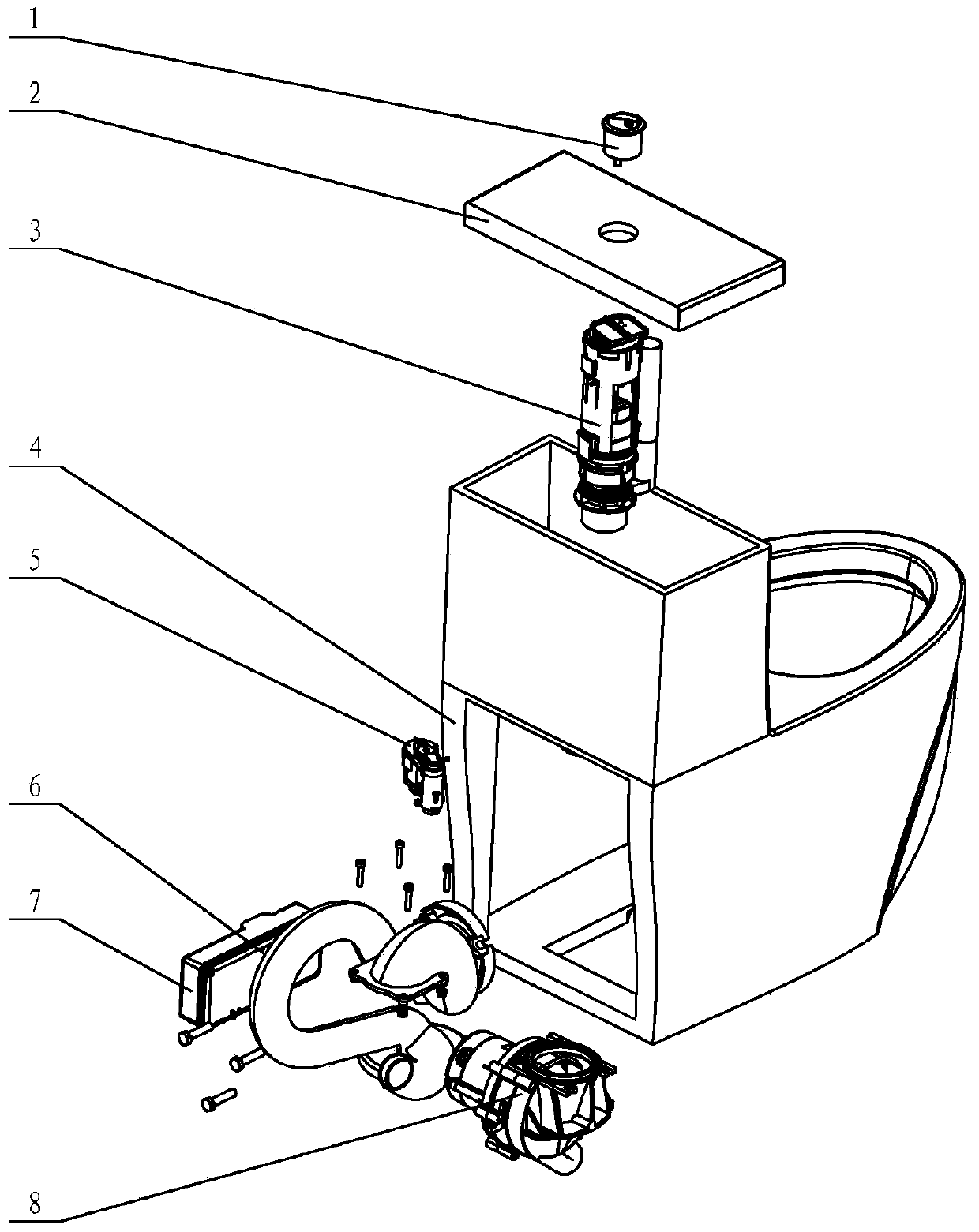

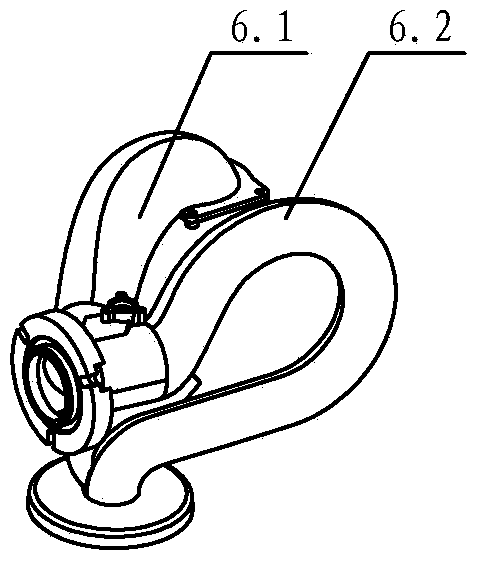

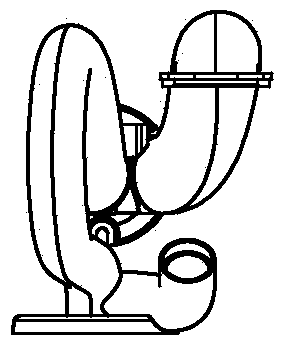

[0045] see Figure 1-Figure 24 , the sewage discharge device of this toilet comprises the water tank 9 that is arranged on the toilet 4, the sewage pipe that is arranged in the toilet 4, the paper shredder 8 is connected in series in the sewage pipe, the drain switch 1 and the water tank cover 2 are arranged on the water tank 9, The drain switch 1 is connected with the drain valve 3 arranged in the water tank 9. The drain switch 1 is provided with a large water button 1.1 and a small water button 1.2. The treated first sewage pipe 6.1 and the second sewage pipe 6.2 that do not need to be crushed, the head end of the first sewage pipe 6.1 and the head end of the second sewage pipe 6.2 are merged into the same opening, and a switch for switching the second sewage pipe is arranged in the opening. The first end of a sewage pipe 6.1 or the first end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com