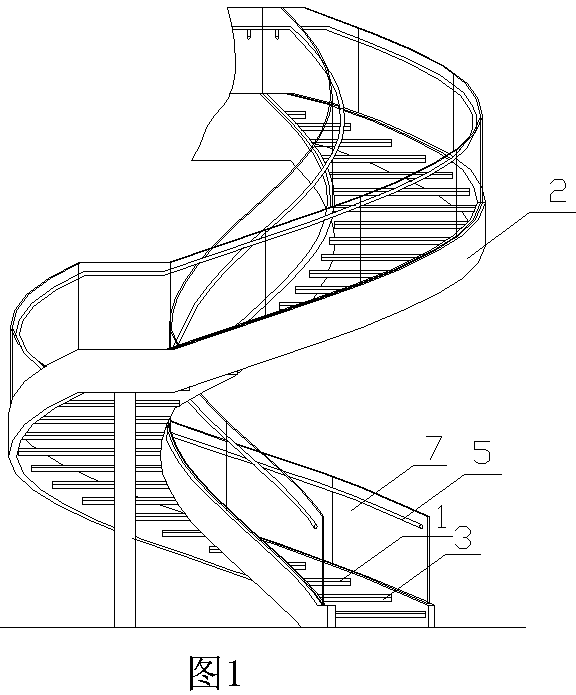

Spiral steel frame staircase and manufacturing method thereof

A spiral and stair technology, applied in the steel frame spiral staircase and its production field, can solve problems such as difficult operation, low efficiency, and potential safety hazards, and achieve the effects of avoiding potential safety hazards, reducing operational difficulty, and preventing misalignment of steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

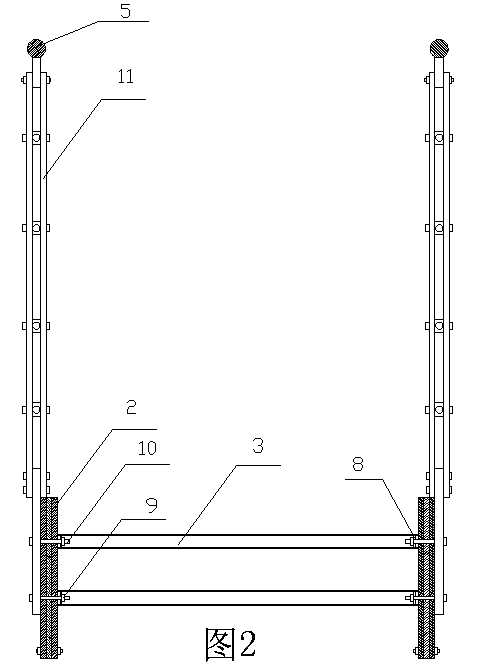

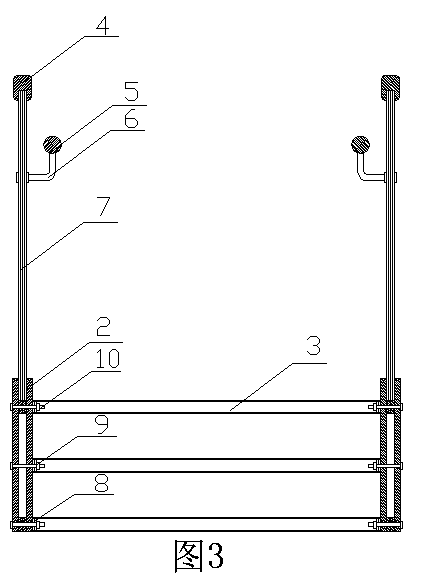

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Method 1: Taking a steel beam composed of three layers of steel plates as an example, cut the width of the steel plate 2 according to the design requirements, then cut the length and grind the edges, and make screw holes for fixing the beam 3 and both ends of the steel plate 2 according to the designed steps , the one in front of the previous step of the 3 holes of the crossbeam and the one behind the next step must be perpendicular, and then the steel plate 2 is bent into the required radian with a three-roll plate rolling machine, and the steel pipe is cut into the size required by the crossbeam 3, and cut for the two beams of the crossbeam 3 The plug 8 at the end, make a center hole on the plug 8, weld the nut 9 on the back of the plug 8, when welding the nut 9, plug a positioning pin or screw 10 on the center hole to prevent the nut 9 from being ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com