Electromagnetic anti-wax device

A wax preventer and electromagnetic technology, applied in instruments, adjusting electrical variables, isolation devices, etc., can solve the problems of weak electromagnetic field and inability to prevent wax, and achieve the effects of increasing production, simple installation, and prolonging wax removal cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

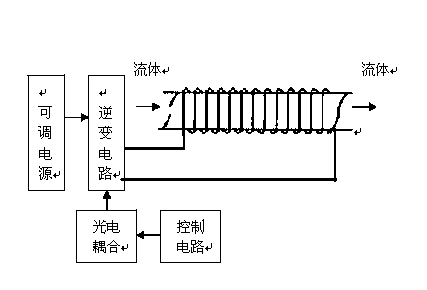

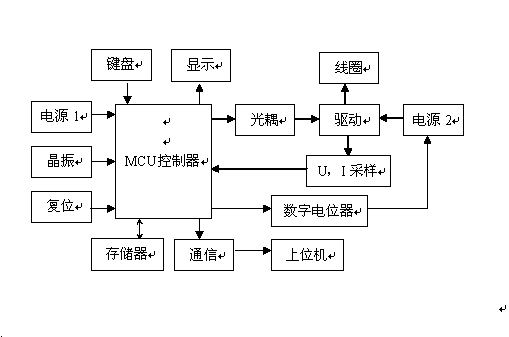

[0020] 1. Dual power supply design (microprocessor power supply voltage 5v, load voltage changes with operating frequency), see Figure three .

[0021] 2. When the current in the load coil is working at 20KHz-30KHz, the peak-to-peak current output reaches 10A.

[0022] 3. In order to improve the working efficiency of the wax preventer, it adopts multi-module design and installation

[0023] The present invention uses the MCU as the core component to generate a square wave signal whose frequency can be changed, and then outputs the square wave signal to the H-bridge drive circuit via the high-voltage side suspension drive IRZI10 (with optical isolation and electromagnetic isolation). Finally, a variable frequency square wave signal with a large current output is sent to the coil.

[0024] Power supply 1 is the power supply of the MCU, and supplies power to the attached devices at the same time;

[0025] Power supply 2 is to supply power to the H-bridge drive circuit to incr...

Embodiment 2

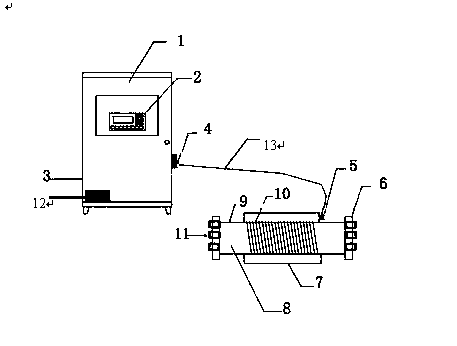

[0029] Electromagnetic wax preventer, its composition includes main machine part 1 and auxiliary machine part 2, described electromagnetic wax preventer, auxiliary machine is made of PPR or the middle outer part of iron-based pipe 9 winding 1.5mm 2 ~3.5mm 2 The double-core cable 10 is connected to the terminal 5 or the aviation plug at both ends, the terminal is fixed on the protective shell 7, and the two ends are welded with iron base or PPR flange 6, which can be connected through the screw 11 on the flange and the oil pipe. Flange connection.

Embodiment 3

[0031] Above-mentioned electromagnetic wax preventer, main engine 1 is made up of display screen 2, and power switch is arranged on said display screen 2, keyboard, working state indicator lamp, display screen, is connected with auxiliary aircraft aviation socket 5 by aviation socket 4, is connected to cable 12 ; The host is connected to the power supply 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com