Dual-light source specular reflection surface measurement system

A specular reflection and surface measurement technology, which is applied in the direction of measuring devices, optical devices, and material analysis through optical means, can solve problems such as complex algorithms, incompleteness, and increased complexity, so as to avoid mutual occlusion and remove speed bottlenecks , high display density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

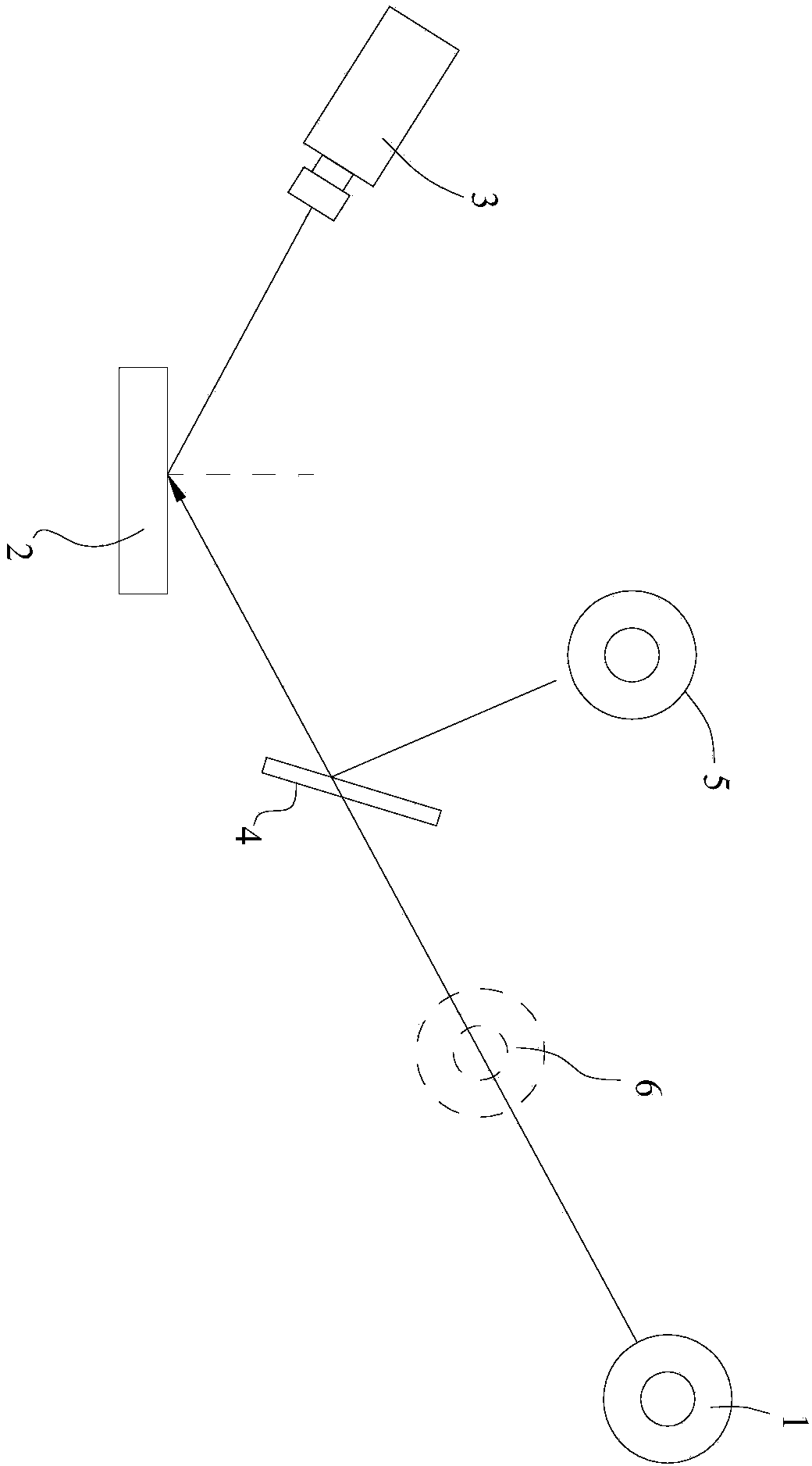

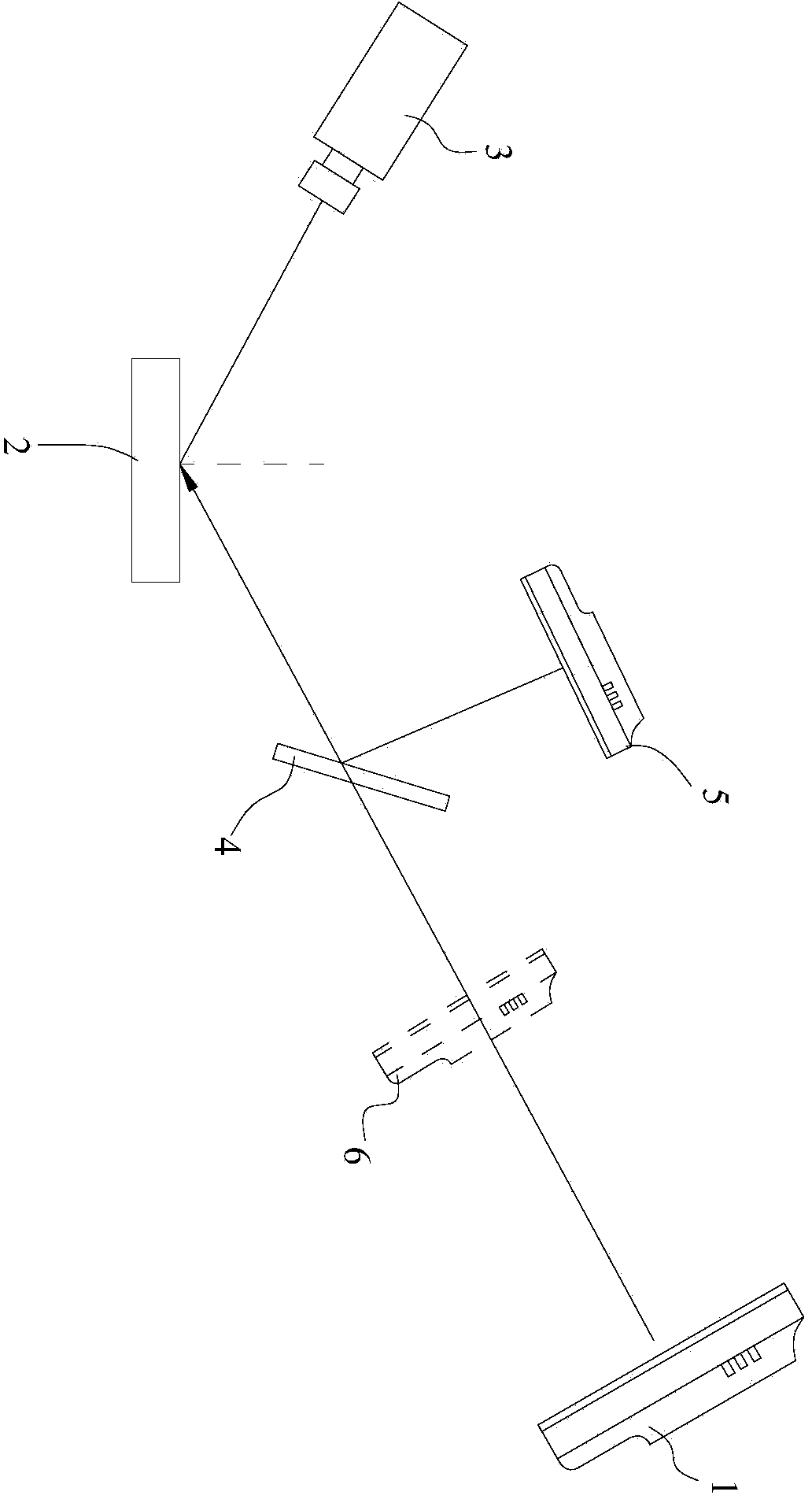

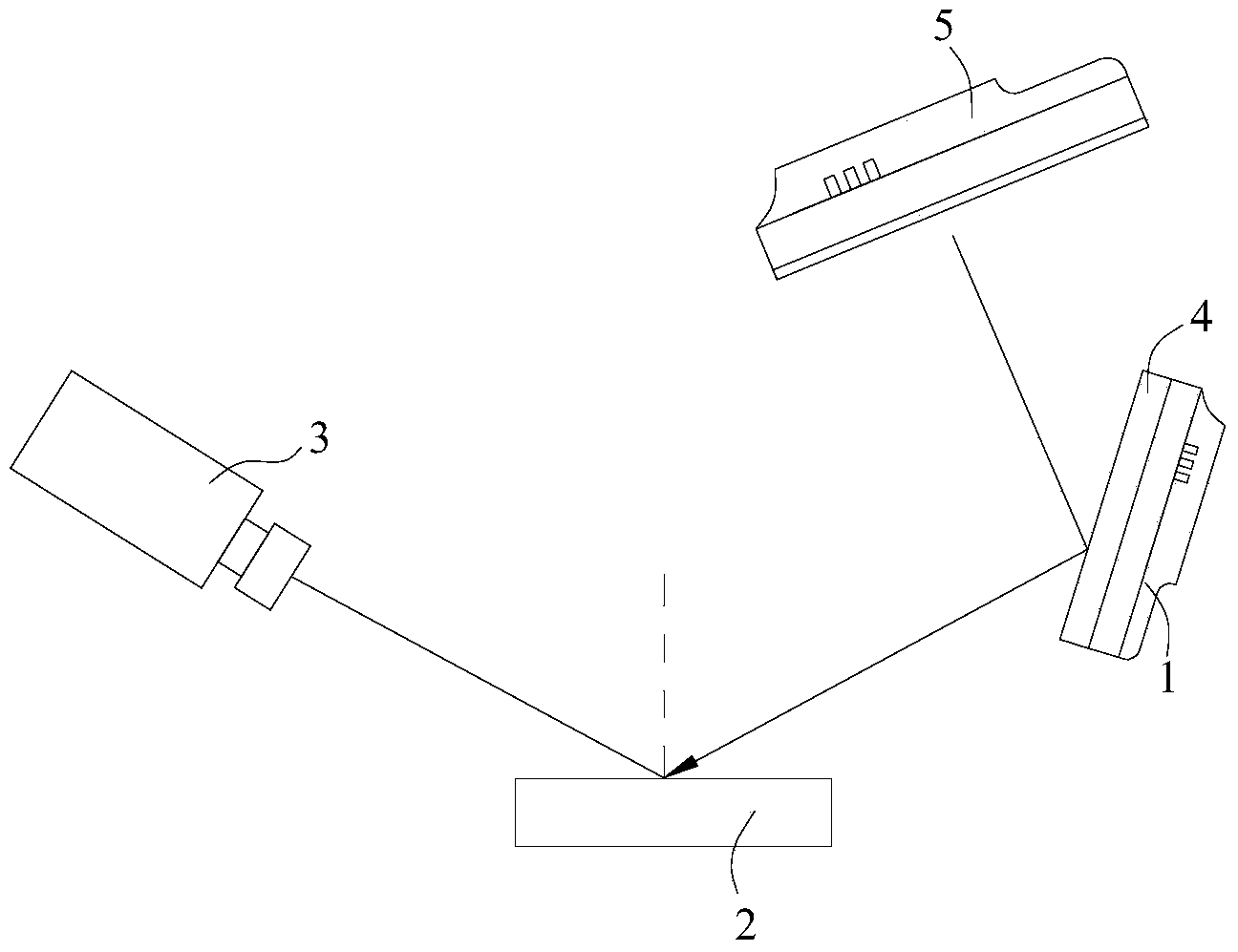

[0016] refer to Figure 1 ~ Figure 3 , the present invention provides a dual light source specular reflective surface measurement system, including a first point light source array 1 and a camera 3 that records the light emitted by the first point light source array 1 and reflected by the object to be measured 2, the first point light source A beam splitter 4 is provided between the array 1 and the object to be tested 2, and a second point light source array 5 is provided on one side of the beam splitter 4, and the light from the second point light source array 5 is reflected by the beam splitter 4 and the object to be tested 2 in turn, and then put into the camera3.

[0017] The working principle of the dual light source specular reflection surface measurement system is as follows:

[0018] When the second point light source array 5 is turned on and the first point light source array 1 is turned off, since the light splitter 4 has the ability of refraction (equivalent to tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com