Method for automatically regulating temperature of flame path of coke oven in heating and combusting procedures on basis of performance evaluation

A technology of fire channel temperature and combustion process, which is applied in control/regulation systems, temperature control by electric means, adaptive control, etc., can solve the problems of inability to automatically adjust, adjustment process dependence, affecting coking production efficiency and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0082] Taking the temperature adjustment of the coke side of the new 1# coke oven of a steel company as an example to describe the specific implementation mode, the temperature of the fire path of the steel company is measured every four hours.

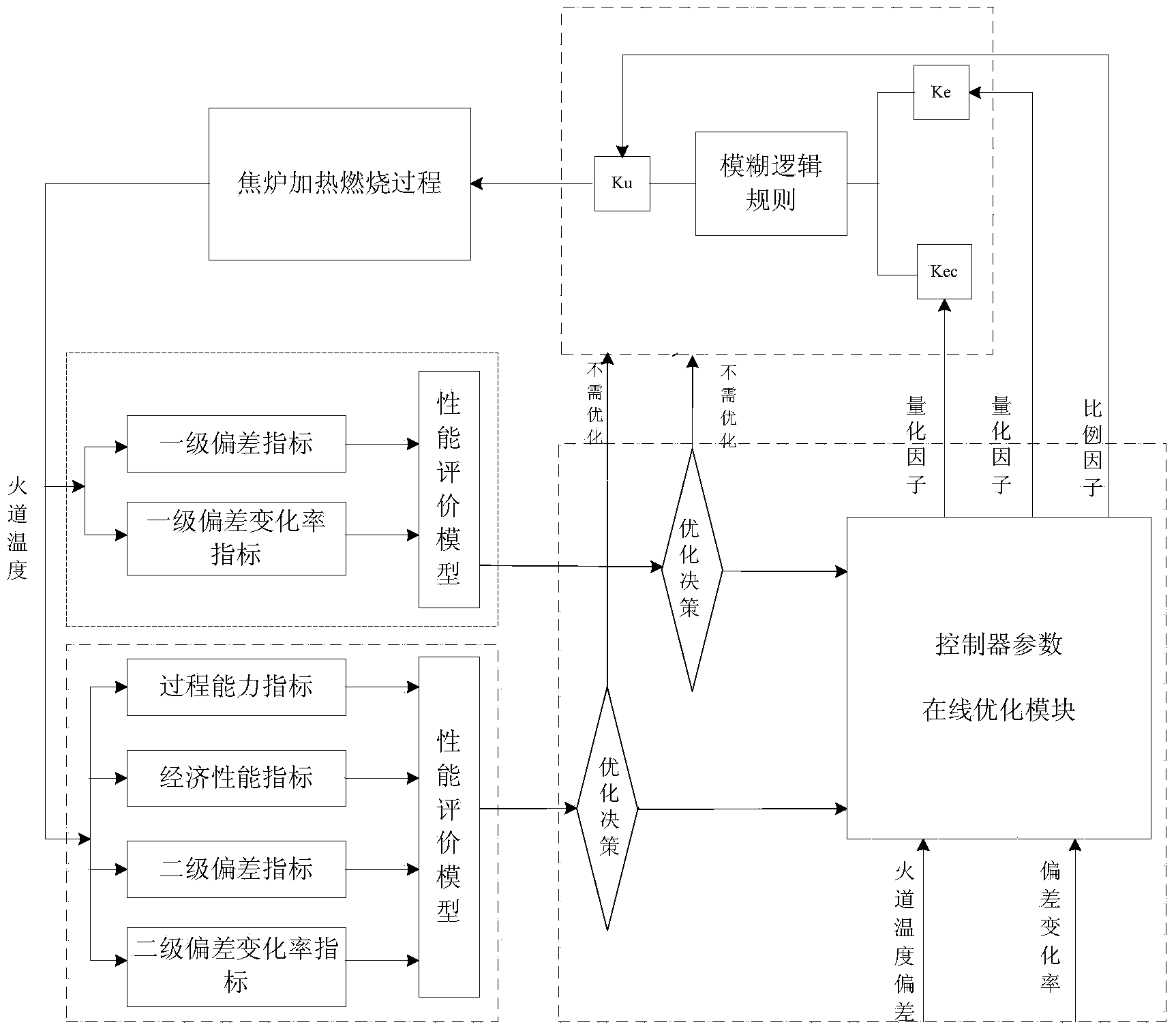

[0083] Such as figure 1 As shown, it is a flowchart of a method for automatically adjusting the flue temperature in the coke oven heating and combustion process based on performance evaluation according to the present invention. By collecting the historical data of the flue temperature operation, a multi-attribute performance evaluation model based on information entropy is established. Collect the data of the current flue temperature operation, use the multi-attribute performance evaluation model based on information entropy to judge the performance level of the current control system, establish a multi-object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com