Crossed annular aligning mark based on TSV (through silicon via) three-dimensional integration process

An alignment mark and cross-shaped technology, applied in the field of microelectronics, can solve problems such as inability to expose copper, small footprint of graphics, increase reliability of TSV three-dimensional integrated devices, etc., achieve high production efficiency, meet high-precision alignment requirements, Scientific and reasonable effect of graphic and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

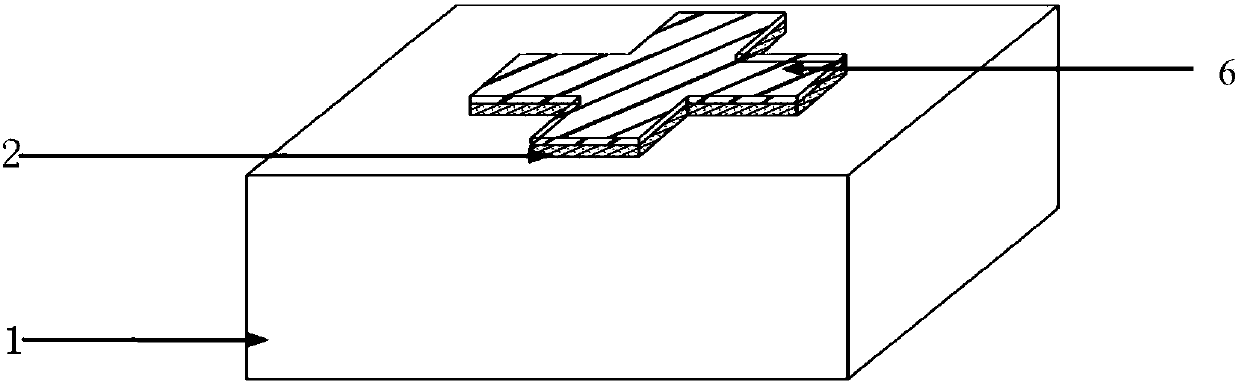

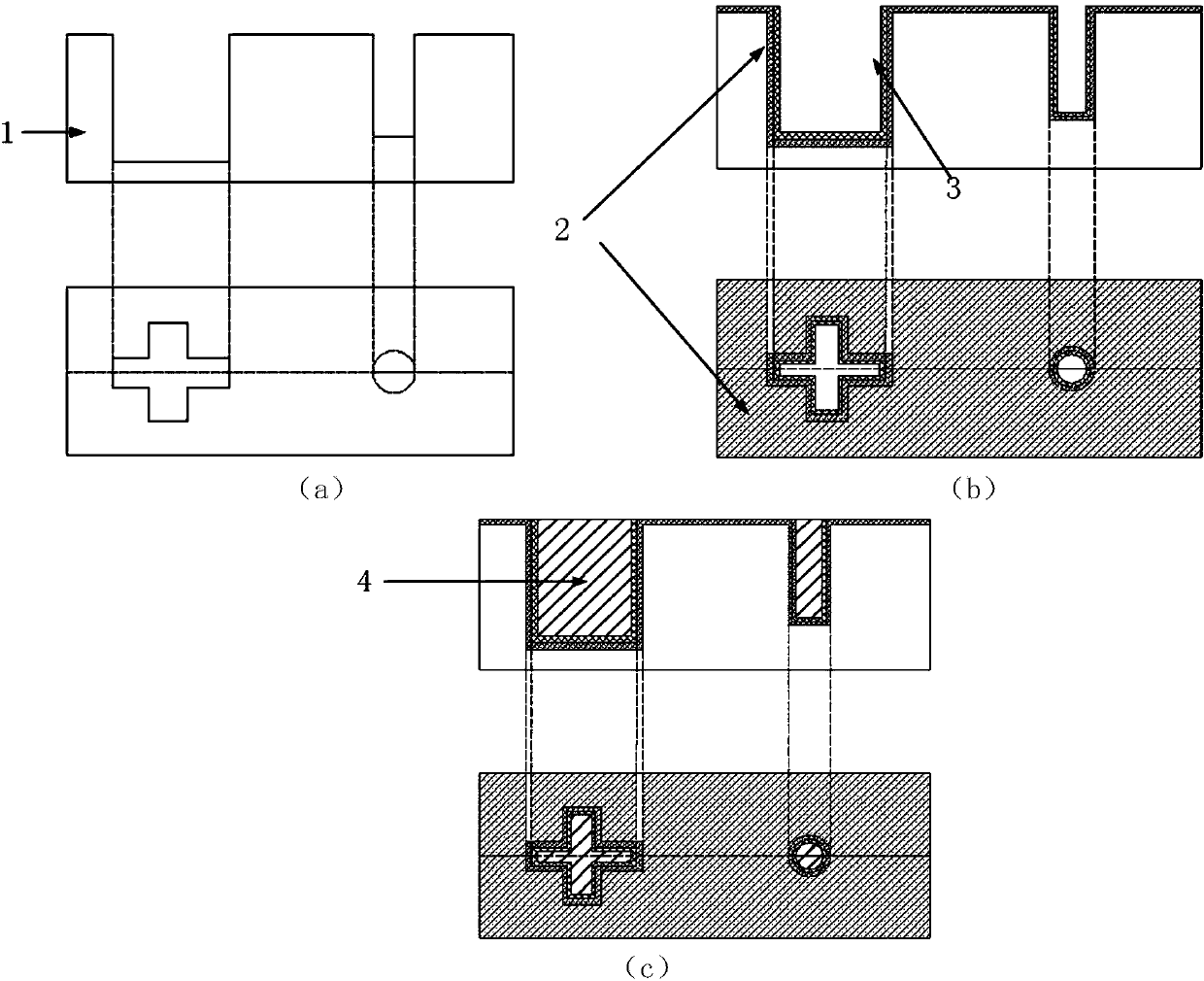

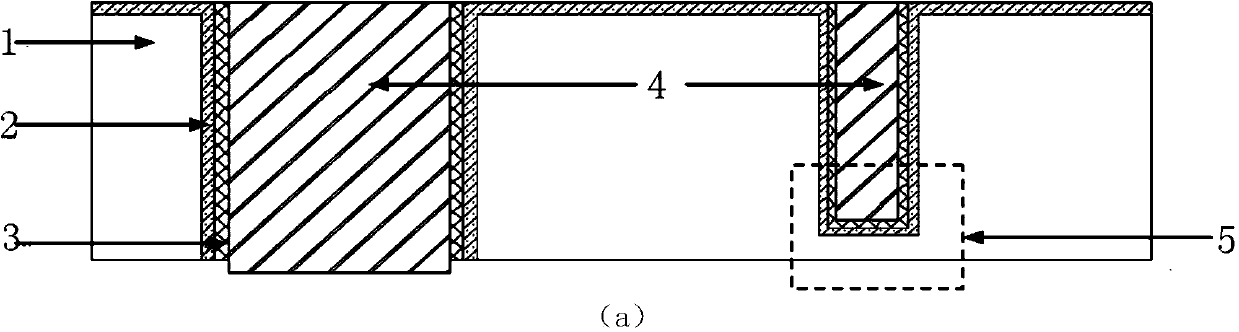

Embodiment 1

[0016] Such as Figure 4 As shown, when the TSV diameter W4 is 20 μm, the corresponding dimensions of the ring-shaped “ten” alignment mark are: L1 is 50 μm, L2 is 30 μm, W1 is 30 μm, and W2 is 30 μm. The size W3 of the annular "ten" opening is (L1-L2) / 2=10μm, the silicon dioxide insulating layer 2 filled inside is 1μm thick, and the tantalum nitride barrier layer / copper seed layer 3 is 0.5μm thick, of which tantalum nitride The thickness of the copper seed layer is 0.2 μm, the thickness of the copper seed layer is 0.3 μm, and the width of the filled copper pillar 4 is 8.5 μm.

[0017] Such as Figure 5 As shown in , when aligning, register the solid "ten" alignment mark on the lithography board with the "ten" annular alignment mark on the wafer, and manually adjust the distance between the above two alignment marks through a contact lithography machine Dimensions W5 and W6, when both W5 and W6 are less than or equal to the registration accuracy of 0.4 μm, the pattern alignme...

Embodiment 2

[0019] Such as Figure 4 As shown, when the TSV diameter W4 is 30 μm, the corresponding dimensions of the ring-shaped “ten” alignment mark are: L1 is 40 μm, L2 is 20 μm, W1 is 40 μm, and W2 is 40 μm. The size W3 of the annular "ten" opening is (L1-L2) / 2=10μm, the silicon dioxide insulating layer 2 filled inside is 1μm thick, and the tantalum nitride barrier layer / copper seed layer 3 is 0.5μm thick, of which tantalum nitride The thickness of the copper seed layer is 0.2 μm, the thickness of the copper seed layer is 0.3 μm, and the width of the filled copper pillar 4 is 8.5 μm.

[0020] When aligning, register the "ten" ring alignment mark on the photolithography board with the "ten" ring alignment mark on the wafer, and manually adjust the distance between the above two alignment marks W5 and W6, when W5 and W6 are less than or equal to the registration accuracy of 0.5 μm, the pattern alignment is completed.

Embodiment 3

[0022] Such as Figure 4 As shown, when the TSV diameter W4 is 40 μm, the corresponding dimensions of the ring-shaped “ten” alignment mark are: L1 is 60 μm, L2 is 30 μm, W1 is 30 μm, and W2 is 30 μm. The size W6 of the annular "ten" opening is (L1-L2) / 2=15μm, the silicon dioxide insulating layer 2 filled inside is 1μm thick, the tantalum nitride barrier layer / copper seed layer 3 is 0.5μm thick, and the tantalum nitride The thickness of the copper seed layer is 0.2 μm, the thickness of the copper seed layer is 0.3 μm, and the width of the filled copper pillar 4 is 13.5 μm.

[0023] When aligning, register the "ten" ring alignment mark on the photolithography board with the "ten" ring alignment mark on the wafer, and manually adjust the distance between the above two alignment marks W5 and W6, when W5 and W6 are less than or equal to the registration accuracy of 0.6 μm, the pattern alignment is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com