Liquid distributor with two stages of runners for chromatographic column

A liquid distributor and two-stage distribution technology, which is applied in the field of chromatography columns, can solve problems such as uneven distribution of liquids and affect chromatography efficiency, and achieve the effects of shortening the longest distance, improving chromatography efficiency, and rational distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

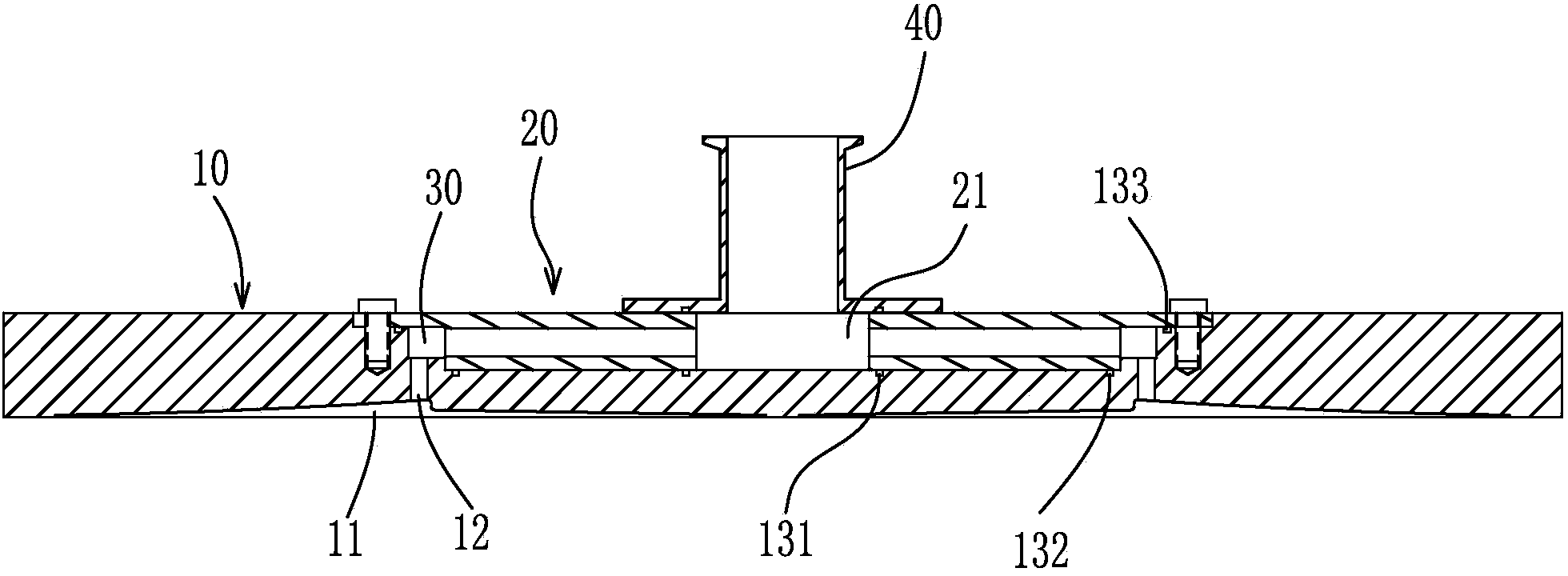

[0016] refer to figure 1 , The liquid distributor of the chromatographic column with the secondary flow channel of the present invention includes a main distribution plate 10 , a secondary distribution plate 20 , an annular flow channel 30 and a liquid outlet or inlet pipe 40 .

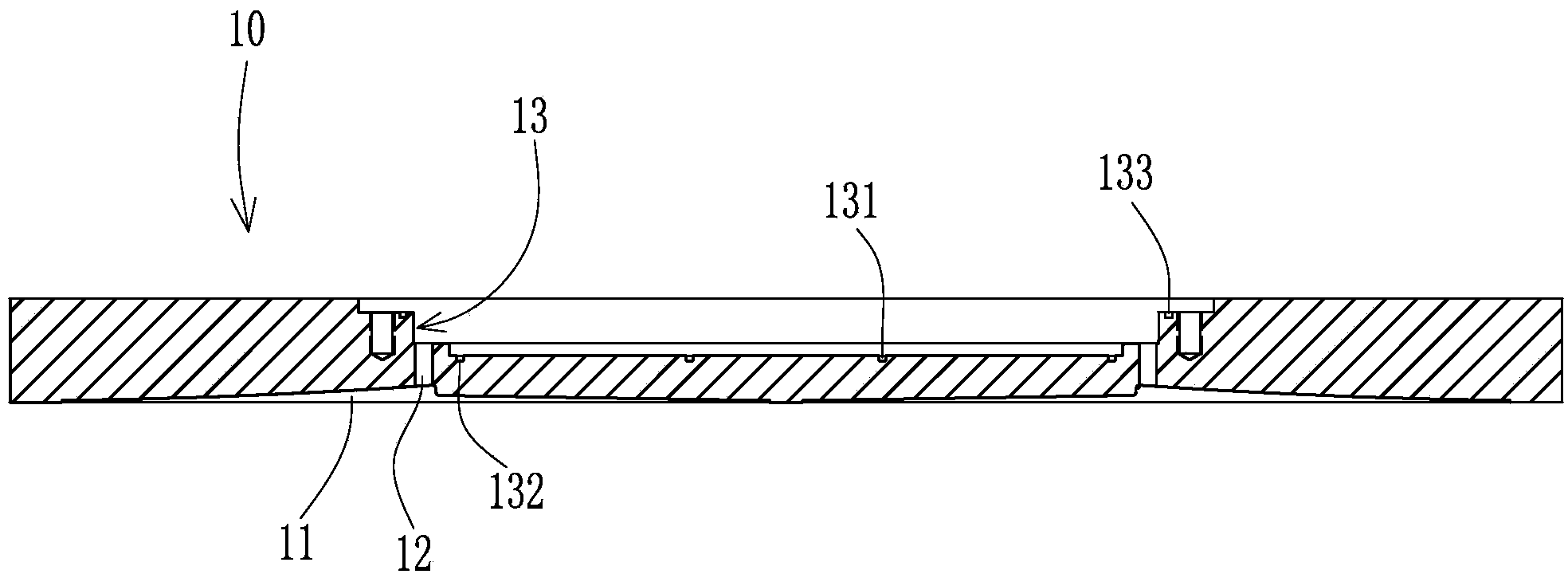

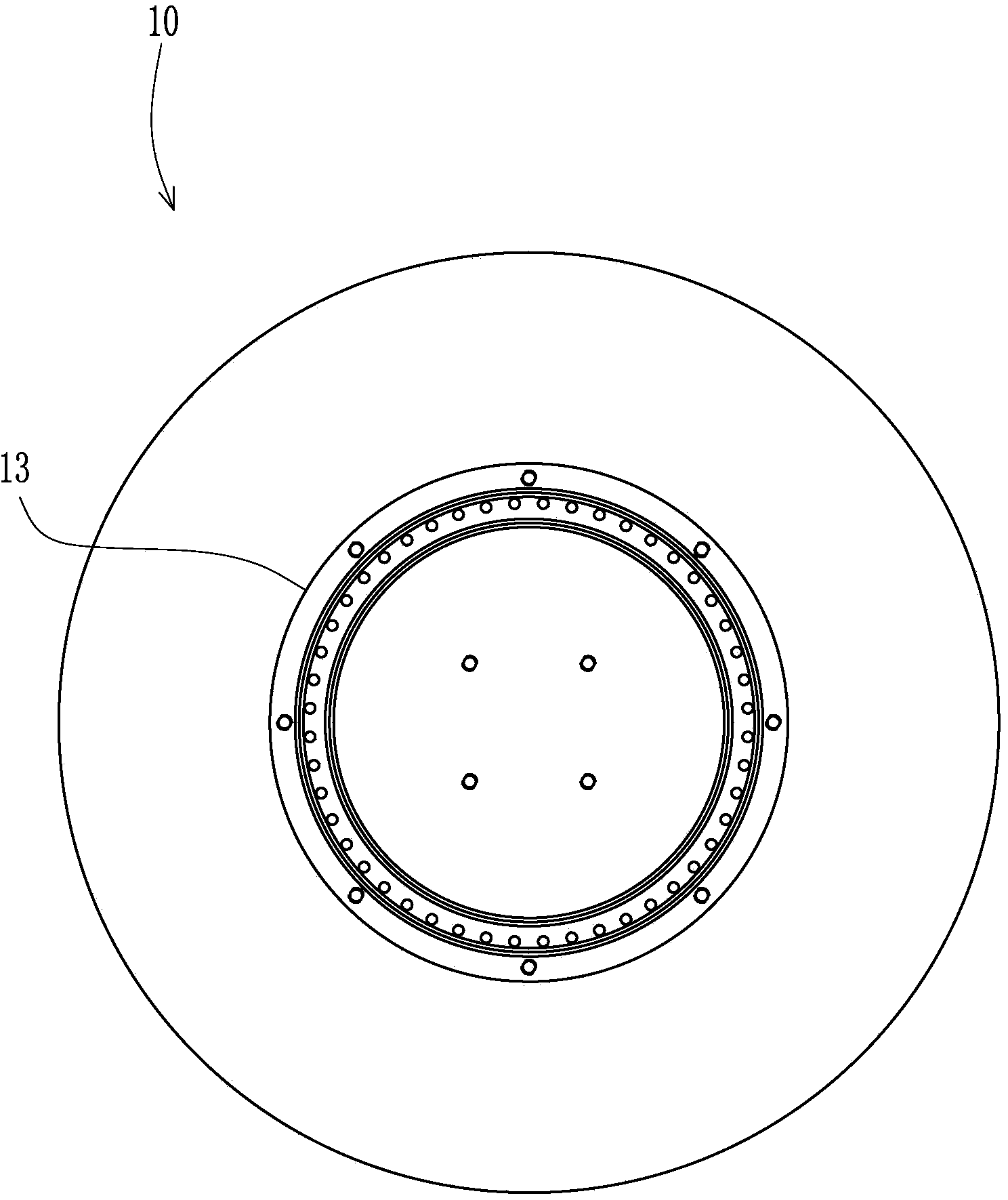

[0017] Such as Figure 2 ~ Figure 4 As shown, the main distribution plate 10 is a circular disc-shaped body, which can be arranged at both ends of a chromatography column (not shown in the figure) in actual application. In this embodiment, a plurality of flow channels 11 are arranged on the lower surface of the main distribution plate 10, and the plurality of flow channels 11 are radially spaced along the circumferential direction of the main distribution plate 10. Each flow channel 11 is composed of two sections of different groove types....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com