Semi-automatic isometric angle extrusion testing device

A technology of equal-diameter angular extrusion and experimental equipment, which is applied in the direction of metal extrusion dies, etc., to achieve the effect of avoiding excessive temperature drop, avoiding excessive temperature drop, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the drawings and embodiments.

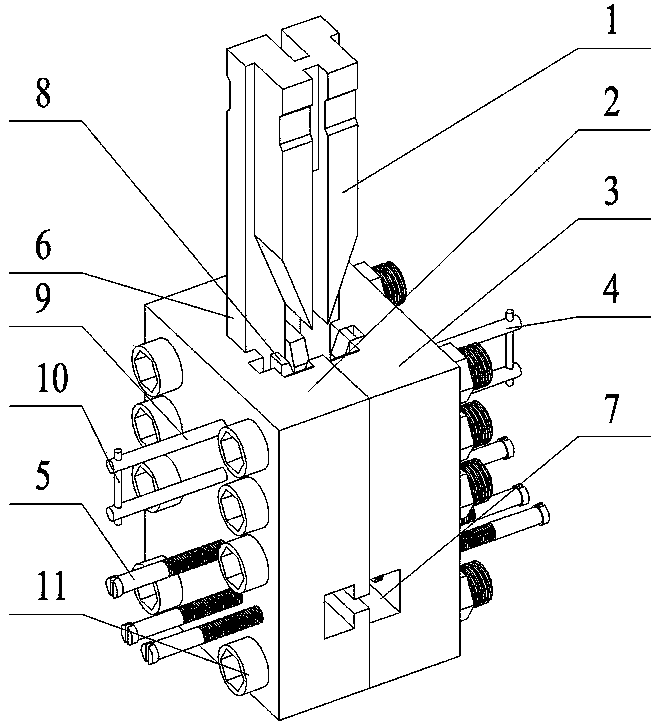

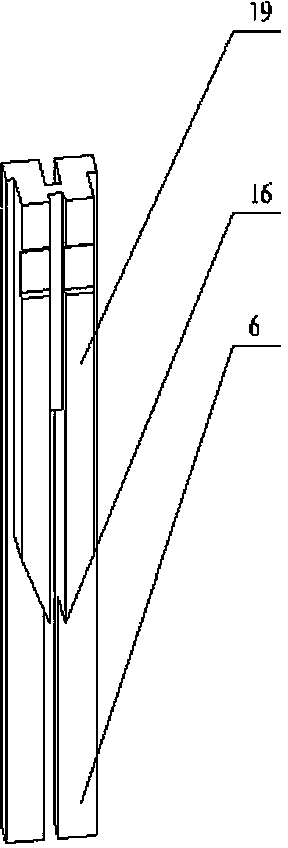

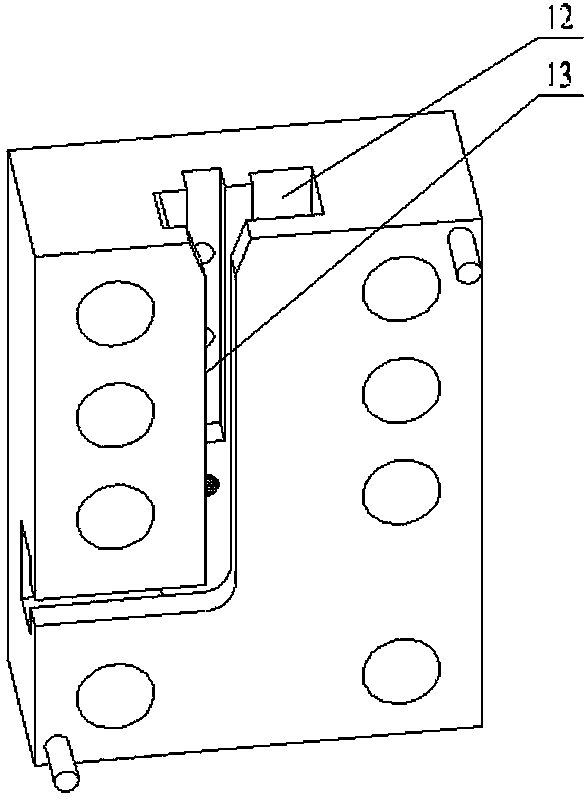

[0032] A semi-automatic equal channel angular extrusion experiment device, including ejector rod 1, lower die 2, upper die 3, sample enclosure device 4, sample ejection screw 5, guide post 6, sample outlet channel 7, sample Baffle 8, baffle stud 9, stud connecting rod 10, nut 11, ejector guide groove 12, equal channel angle channel 13, baffle groove 14, small slope 15, large slope 16, smooth hole 17, threaded hole 18 and the H-shaped upper part 19, the lower mold 2 and the upper mold 3 are fixed to each other through the cooperation of a plurality of nuts 11 and screws. The ejector rod 1 is installed in the upper gap between the lower mold 2, the upper mold 3 and the lower mold 2. Both sides of the upper mold 3 through the light hole 17 are equipped with a sample enclosure device 4, a sample ejection screw 5, the lower mold 2, and the upper mold 3 are equipped with a sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com