Detachable horizontal machining centre spindle box and manufacturing method

A machining center and spindle box technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient installation, inflexible precision adjustment, and difficult processing of parts, so as to reduce the difficulty of assembly and save The effect of eliminating the scraping process and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and examples.

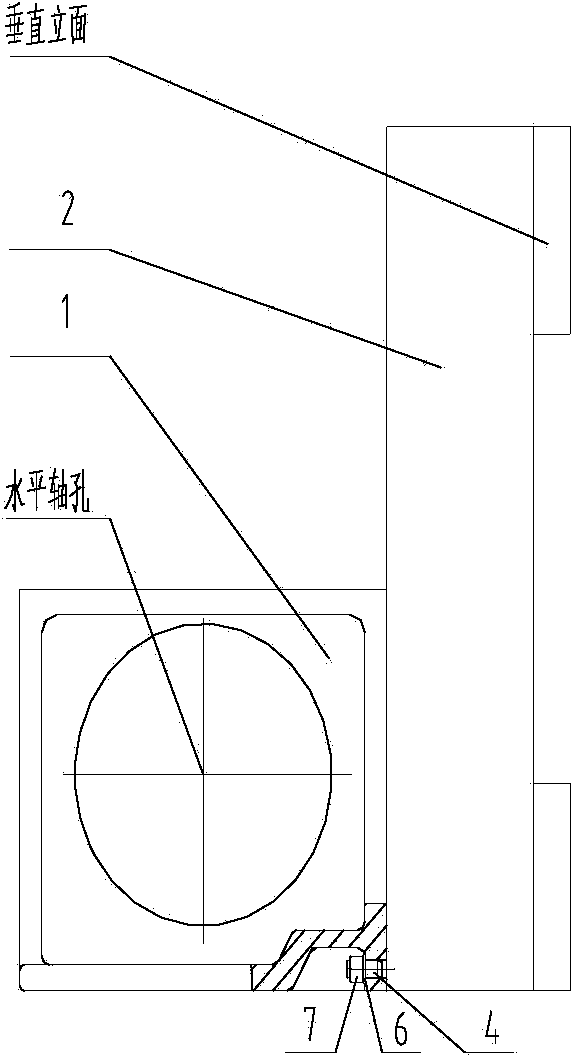

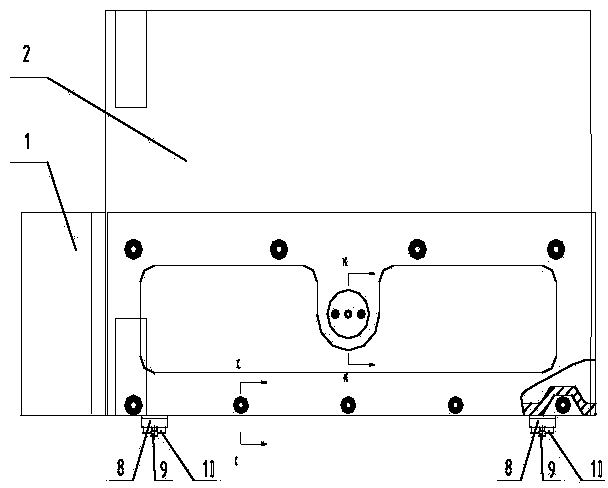

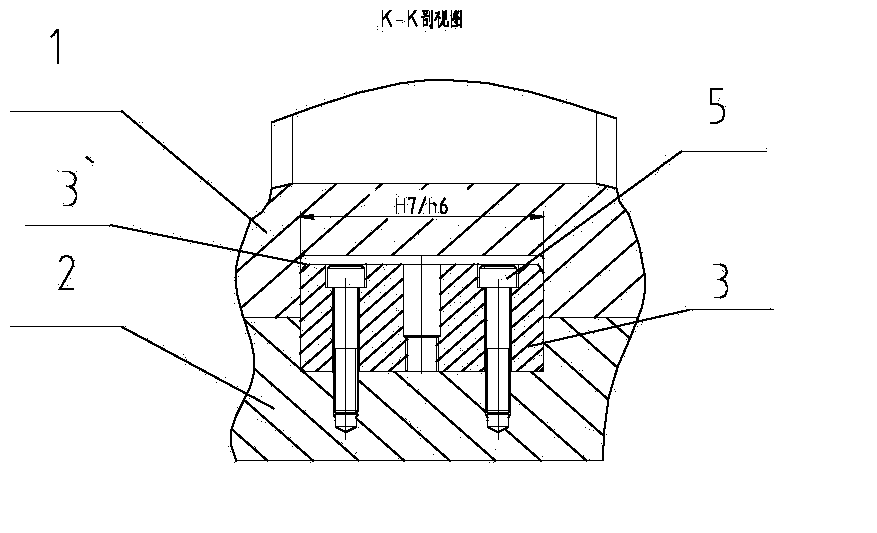

[0015] Such as figure 1 , figure 2 The detachable spindle box of the horizontal machining center shown, the spindle box includes two parts: the box body 1 and the slide plate 2, and its characteristic lies in the structure: the facade part connected with the column and the main part of the spindle box are separated into two parts The two parts are respectively a box body 1 with a horizontal shaft hole and a slide plate 2 with a vertical facade, and the contact surfaces of the box body 1 and the slide plate 2 are respective processing surfaces. Finishing the plane where the two parts are in contact with each other. The finishing of the contact surface of the two parts can be done by milling or grinding. This process can be completed by using a three-axis machine tool. After the contact surface is processed, the CNC boring machine can be used for the machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com