Manufacture method of high-temperature resistant glass reinforced plastics mould

The technology of a glass fiber reinforced plastic mold and a manufacturing method, which is applied in the field of aviation material composite materials, can solve the problems of high cost of metal molds, too large difference in thermal expansion coefficients of materials, and high cost, and solve the problems of high temperature resistance and cost, high temperature resistance performance, and high temperature resistance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below.

[0021] A method for manufacturing a high-temperature-resistant glass fiber reinforced plastic mold, based on glass fiber-reinforced polymer-based composite material technology, comprising the following steps:

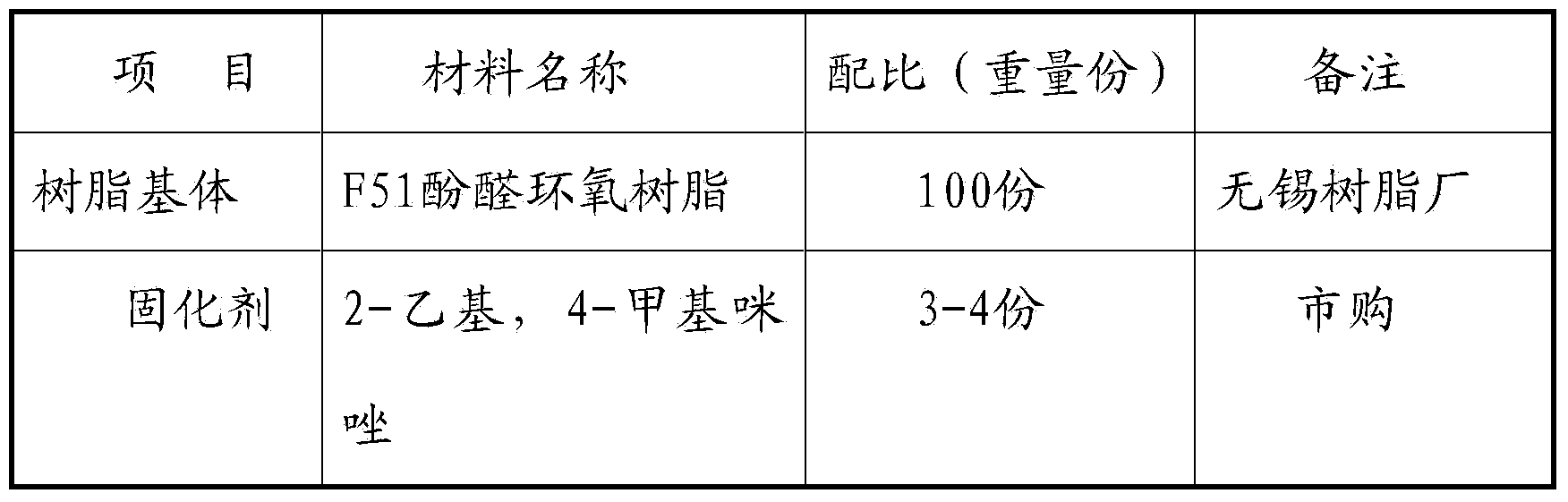

[0022] The first step: prepare the glue solution for FRP mold making. The formula is shown in Table 1. When preparing the glue, first preheat the F51 resin to 60°C-80°C, after the resin is completely softened, add 2-ethyl, 4-methylimidazole, and stir well. (The glue preparation materials are all commercially available)

[0023] Table 1 Resin Glue Formula for Mold Making

[0024]

[0025] The second step: FRP mold forming (for example: concave mold). Calculate the required glue solution according to the glue content of 68%. On the transition mold coated with the liquid release agent CHEMLEASE PMR (the transition mold selects a suitable material according to the demoulding temperature, such as: e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com