Rear drive axle assembly

A technology of rear drive axle and assembly, which is applied in the field of rear drive axle assembly of mini-vehicles, can solve the problems affecting the reliability of the rear axle of mini-vehicles and the NVH performance of the whole vehicle, and achieve the effect of reducing abnormal vibration and solving abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

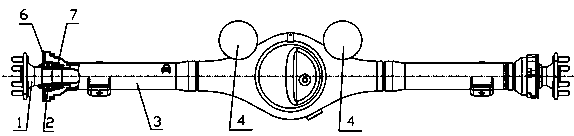

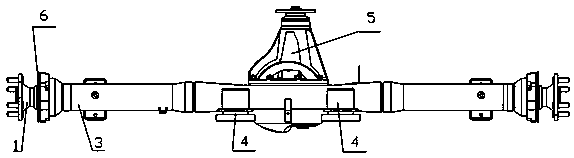

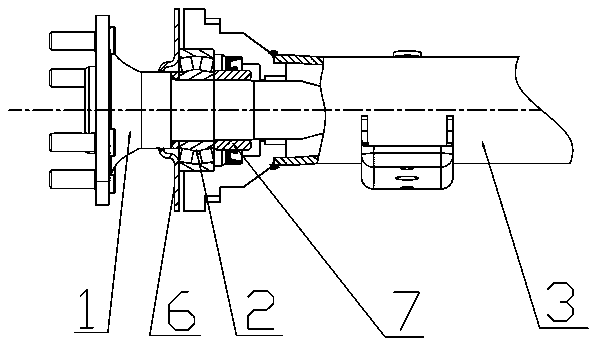

[0016] Such as figure 1 , 2 , the rear drive axle assembly shown in 3, including the axle housing 3, the final reducer 5, the half shaft 1 and the shock absorbing block 4, the half shaft 1 is supported in the axle housing through the spherical roller bearing 2 and assembled with the The main reducer 5 in the middle of the axle housing is connected, and the self-aligning roller bearing 2 is interference fit with the half shaft 1 . During assembly, the self-aligning roller bearing 2 is pressed on the axle shaft 1 through the bearing retaining ring 7, and then the axle shaft 1 is inserted into the axle housing 3, so that the spherical roller bearing 2 is supported in the axle housing 3, and then the bearing The pressure plate 6 is fixed on the axle housing.

[0017] Compared with deep groove ball bearings, double row ball bearings and tapered roller bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com