Bionic leakage-proof package bottle

A packaging bottle, bionic technology, applied in packaging, transportation and packaging, bottles and other directions, can solve the problems of high production cost, waste of users, complex structure, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

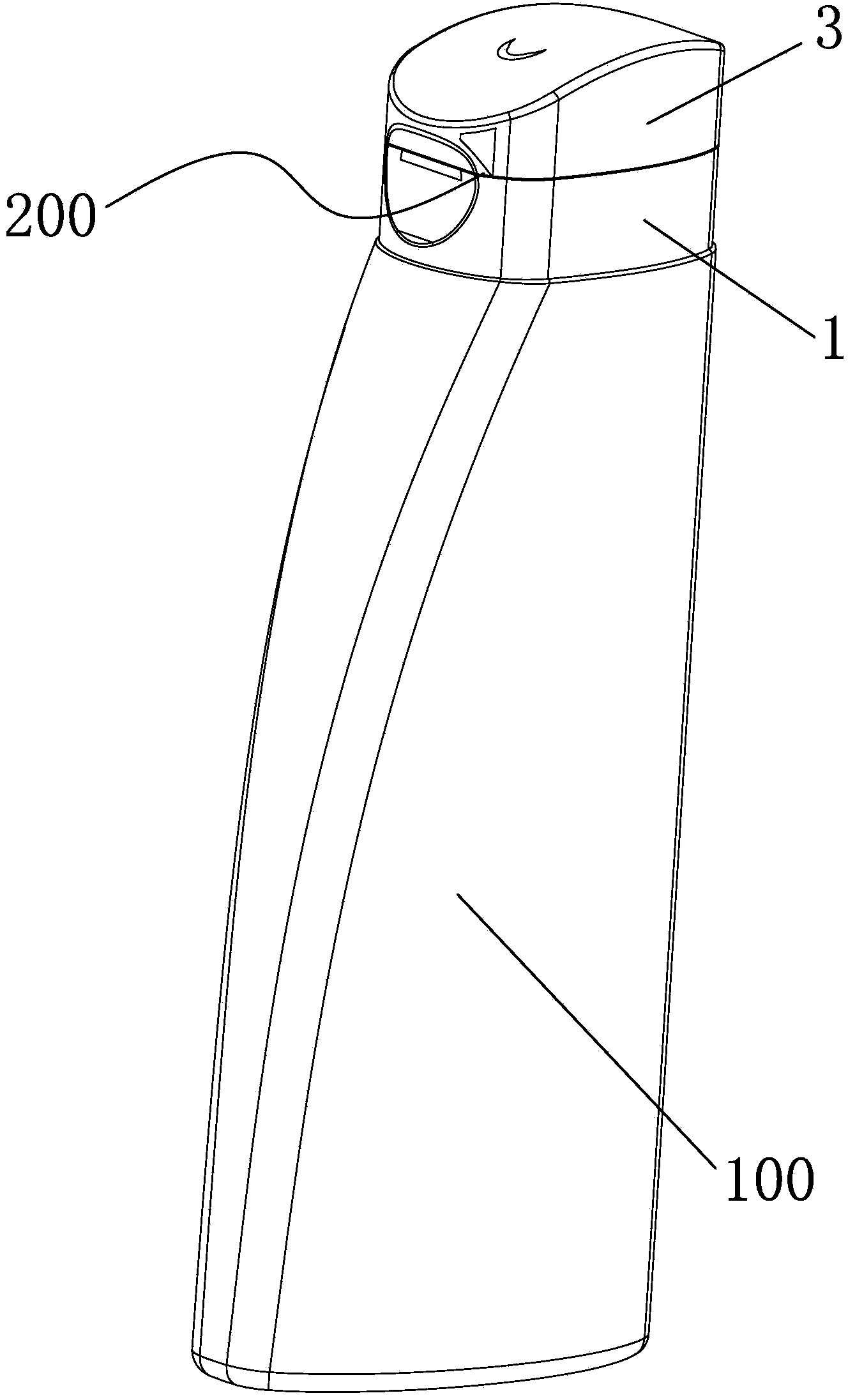

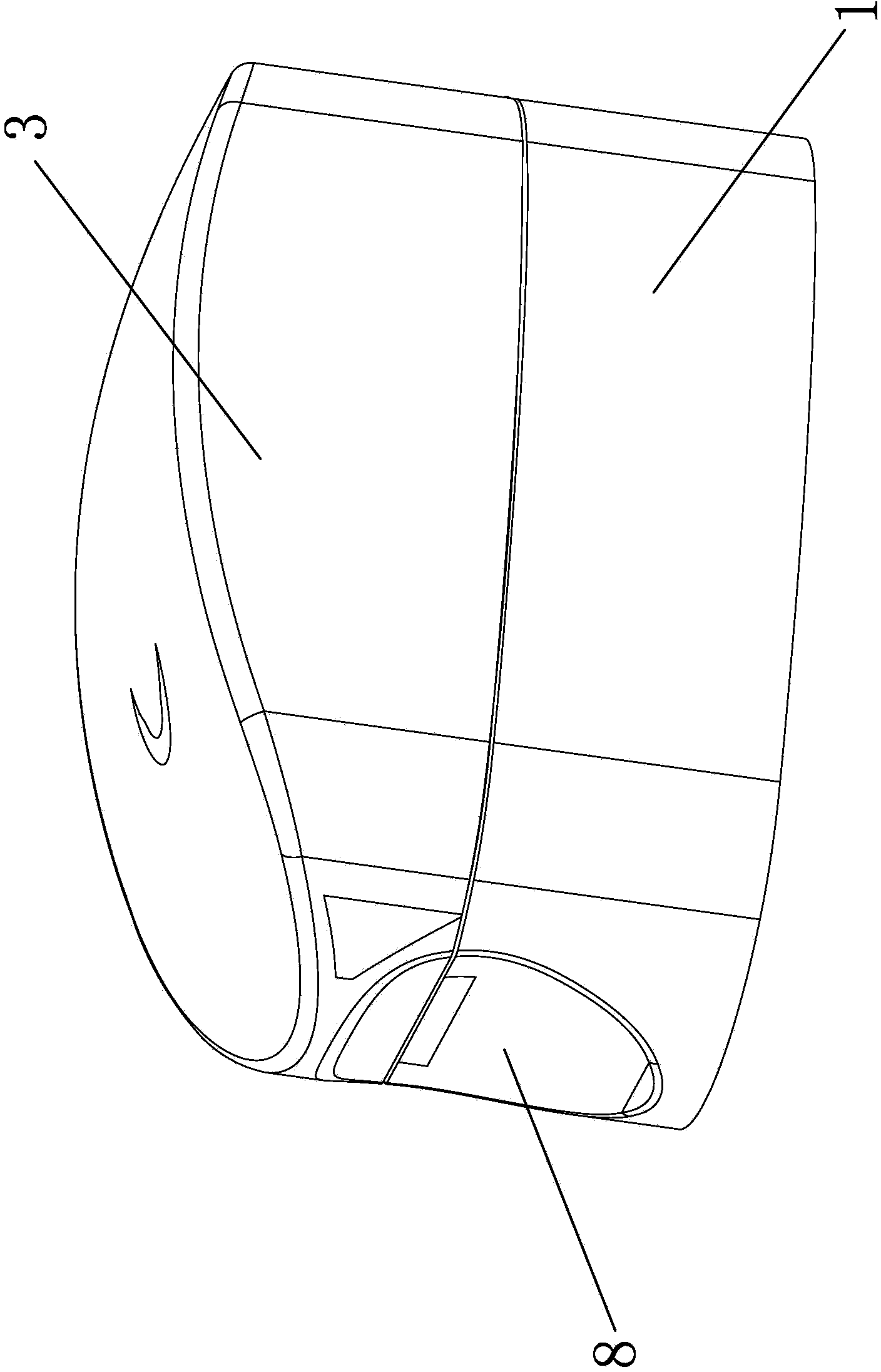

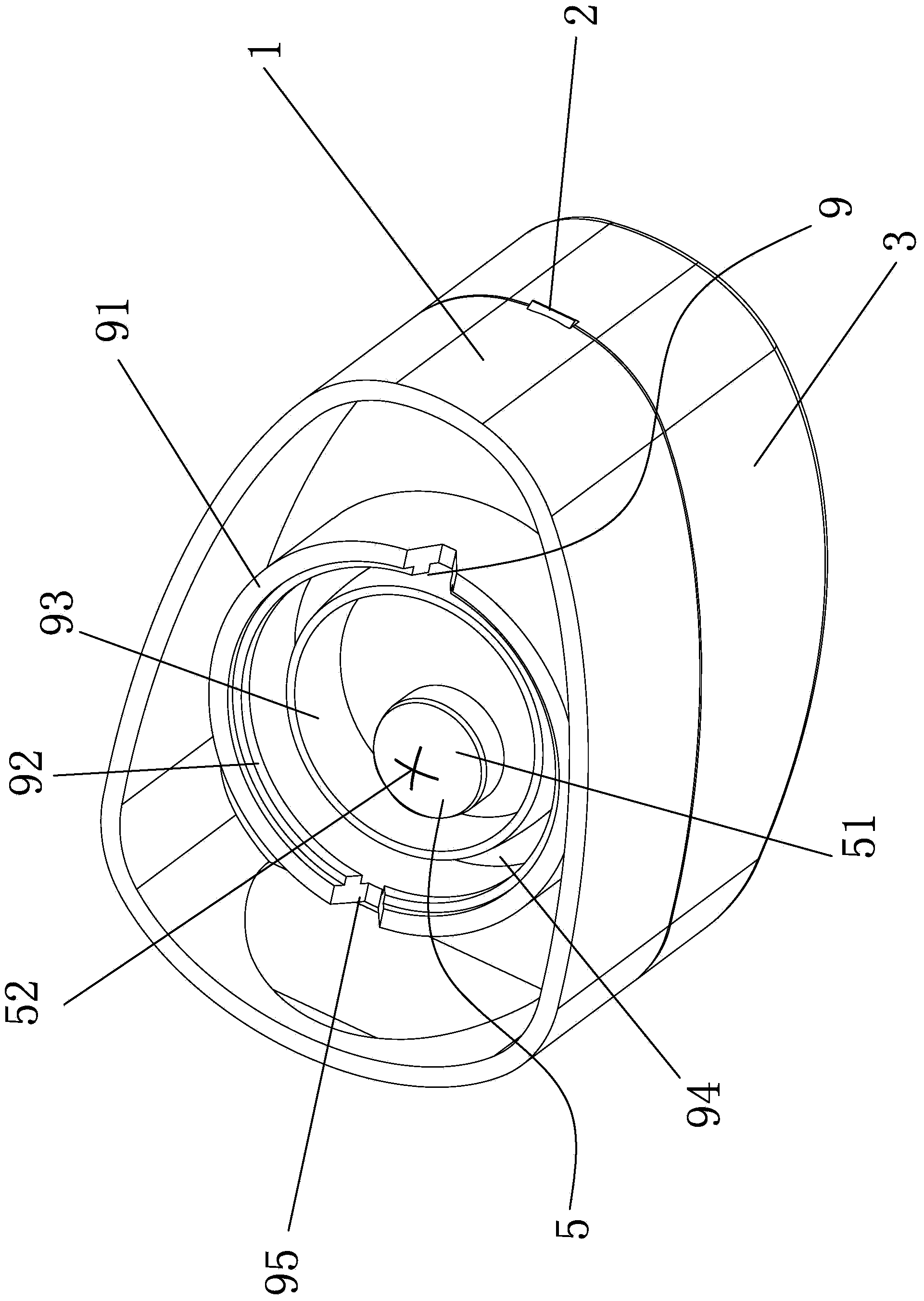

[0030] like Figures 1 to 8 The shown bionic leak-proof packaging bottle includes a bottle body 100 and a bottle cap 200. The bottle cap 200 includes a cap body base 1 on which is hinged through a hinge member 2 and can be turned over. The opened face cover 3 is provided with an opening 4 on the cover base 1. When the opening 4 is provided with a sealing switch device 5 that can be opened to form a channel when the cover base 1 is squeezed, the bottle body 100 includes a The bottle body 10, the bottle body 10 includes a PE inner layer 110, a PP outer layer 120 is arranged outside the PE inner layer 110, and a PP outer layer 120 is arranged on the upper end face of the bottle body 10 and communicates with the inner cavity of the bottle body 10. The bottle mouth 20 is provided with a limit bump 30 on the outer wall of the bottle mouth 20, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com