Pneumatic compacting self locking type oil tank gas recycling and sealing device arranged on top of train

A technology of pneumatic pressing and sealing device, used in packaging, transportation, packaging, containers, etc., can solve the problems of poor sealing effect, poor sealing performance of sealing device, difficult operation, etc., and achieve reliable sealing, reliable sealing effect and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

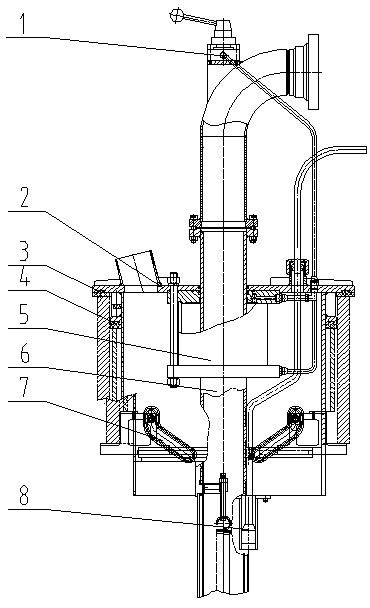

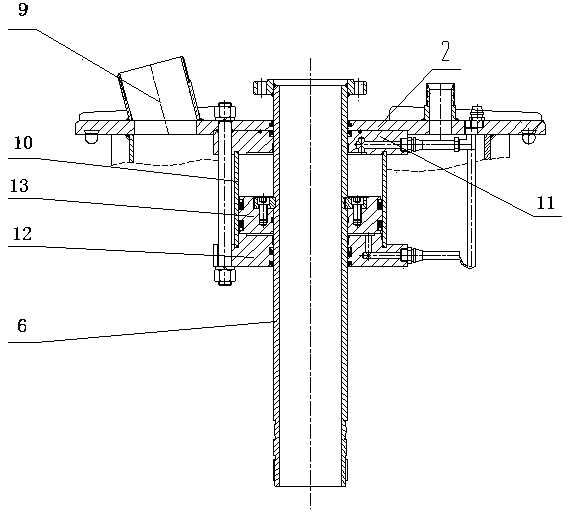

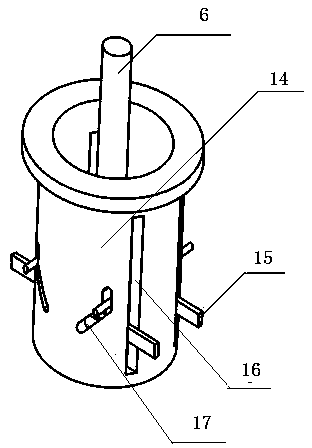

[0017] A pneumatic compression self-locking oil tank gas recovery sealing device on the top of a train, including a vertical pipe 6 and a sealing cover 2 matching with the tank opening on the top of the train tank car. 19 is provided with an oil and gas recovery port 9 on the sealing cover body next to the sealing cover, and a cover cylinder assembly is provided at the bottom of the sealing cover. The cover cylinder assembly is provided with an outer cylinder 14. The surface is docked, the oil and gas recovery port 9 is arranged on the sealing cover 2 in the outer cylinder, a rubber gasket is arranged on the sealing cover along the outer wall of the outer cylinder, a vertical pipe lifting cylinder 5 is arranged in the outer cylinder 14, and a There is a bottom withholding mechanism 7 matched with the inner edge of the tank mouth of the train tank car. The vertical pipe lifting cylinder 5 includes a cylinder block 10, an upper end cover 11 and a lower end cover 12 which are set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com