Integrated processing system for industrial flue gas, wastewater, urban regenerated water and circulating cooling water

A technology of circulating cooling water and industrial flue gas, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as the impact of national fiscal revenue, and achieve a hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

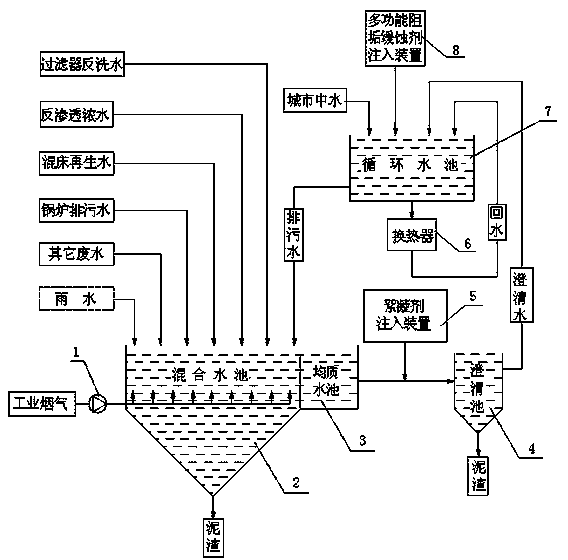

[0012] Integrated treatment system for industrial flue gas and waste water, urban reclaimed water, and circulating cooling water, consisting of heat exchanger 6, circulating pool 7, mixing pool 2, homogeneous pool 3 and clarification pool 4, heat exchanger 6 and circulating pool 7 The circulation is connected, the industrial flue gas is connected to the mixing pool 2 through the pipeline and the fan 1, the waste water pipeline and the rainwater pipeline are connected to the mixing pool, the homogeneous pool 3 is connected to the mixing pool 2, and the homogeneous pool 3 is connected to the clarified pool 4. The communication pipe between the pool 3 and the clarified pool 4 is provided with a flocculant injection device 5, the clarified pool 4 is communicated with the circulating pool 7 through a pipeline, and the bottom of the circulating pool 7 is communicated with the mixing pool 2 through a pipeline, and in the circulating pool 7 A multi-functional scale and corrosion inhibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com