Ship lift nut column installation auxiliary adjustment method

An adjustment method and installation auxiliary technology, which are applied in the vertical lifting of ship machinery, ship lifting devices, construction and other directions, can solve the problems of large size and weight of a single piece of nut column of a safety locking structure, high installation quality requirements, and technical difficulty, etc. Solve construction difficulties, facilitate processing and production, and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

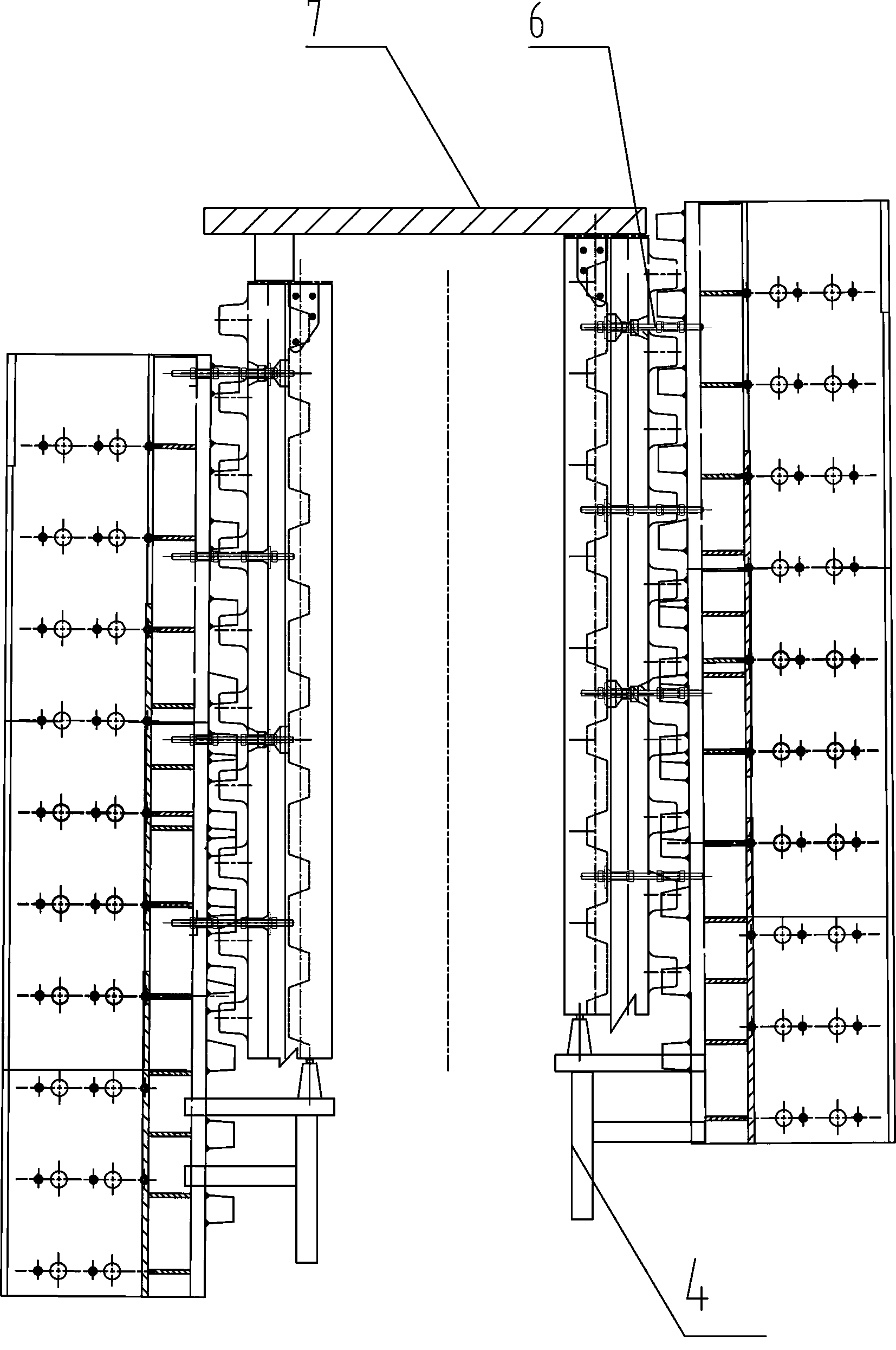

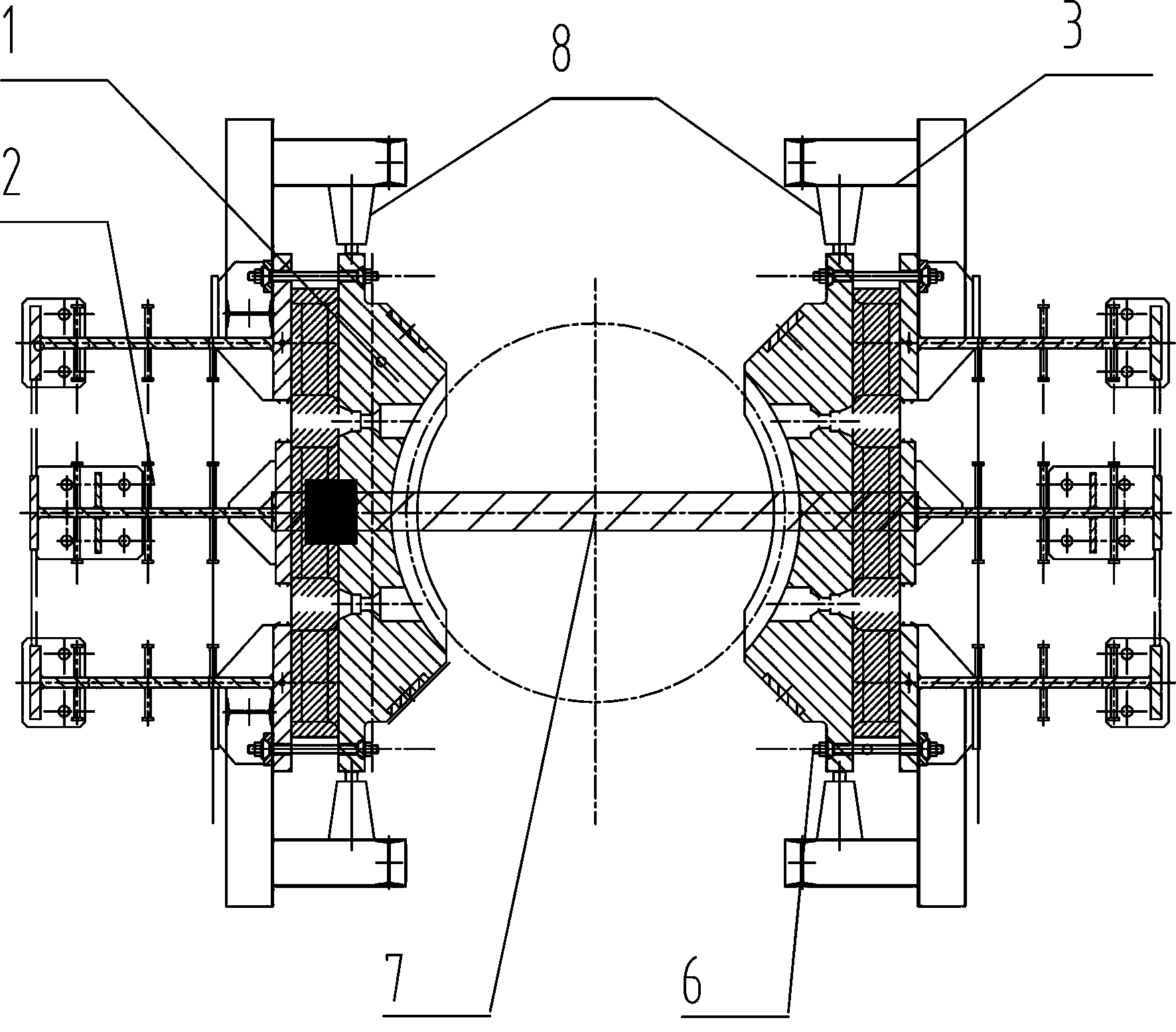

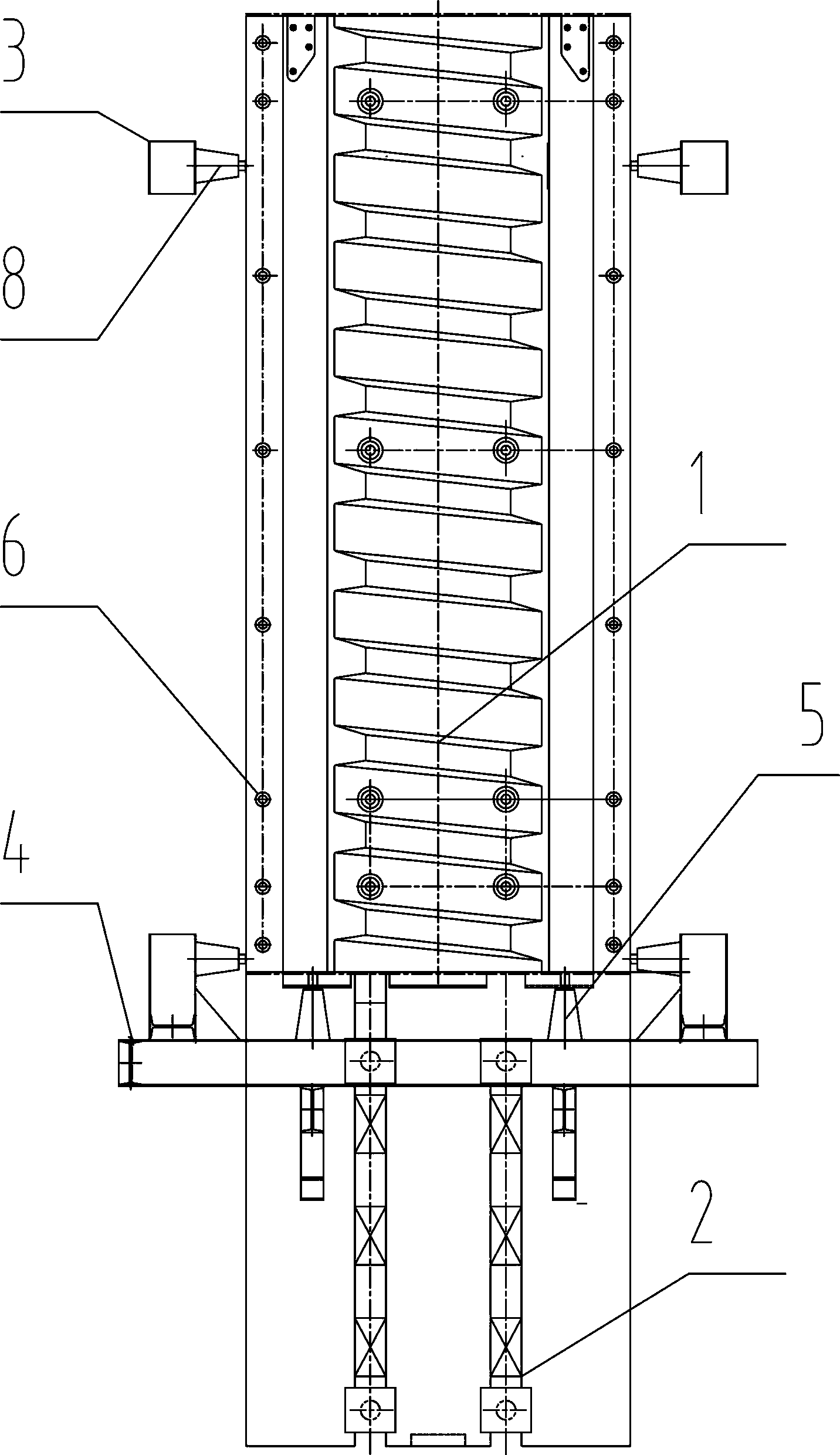

[0030] See attached Figure 1-3 As shown, a ship lift nut column installation auxiliary adjustment method includes the following steps:

[0031] 1) Weld the first section steel tooling 4 on the second-stage embedded part 2 at the bottom of the nut column;

[0032] 2) Arrange the bottom jack 5 on the first section steel tooling;

[0033] 3) Hoist and lower the nut column 1 onto the bottom jack;

[0034] 4) Weld 4 sets of second-shaped steel tooling 3 on the position of the second-stage embedded parts corresponding to the four corners of the nut column;

[0035] 5) Arrange lateral jacks 8 between 4 sets of second-shaped steel tooling 3 and nut columns;

[0036] 6) Arrange the 16 sets of process screw rods 6 through the nut columns and the bolt holes on the panel of the second-stage embedded parts;

[0037] 7) Complete the positioning of a pair of 2-piece nut columns through the above steps;

[0038] 8) Arrange the measuring tooling 7 on the top of the two nut columns;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com