Tail gas pipeline capable of generating electricity efficiently

An exhaust gas and pipeline technology, applied in exhaust devices, engine components, combustion engines, etc., can solve the problems of pollution, low heat exchange efficiency, small power generation equipment, etc., and achieve high market prospects, high cost performance, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

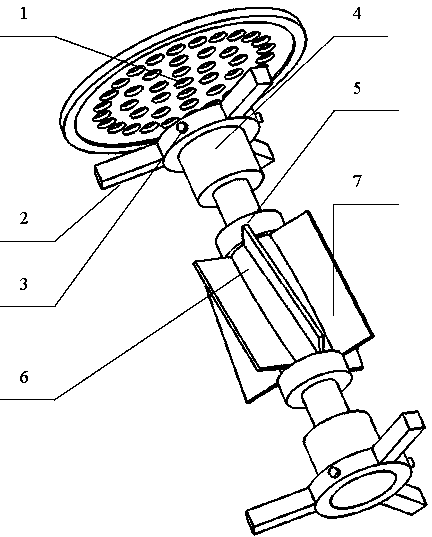

[0025] The present invention is an exhaust gas pipeline capable of generating electricity with high efficiency. There is a power generating device in the pipeline. The generator is vertically installed in the exhaust pipeline, and the blades are arranged obliquely. There is a spiral air-introduction channel in the pipeline, which can greatly improve the power generation rate of the exhaust gas, and Ordinary pipelines can be refitted, so they have excellent market prospects.

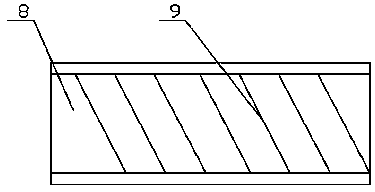

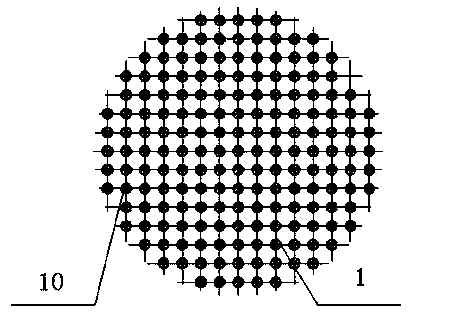

[0026] As an embodiment of the present invention, the present invention provides an exhaust gas pipeline that can efficiently generate electricity, including a mounting bracket 2, a generator 4, a rotating shaft 6, blades 7 and an exhaust gas pipeline 8, and the blades 7 are obliquely arranged on the outside of the rotating shaft 6, The blades 7 revolve around the rotating shaft 6 for one week, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com