Inlet air intercooling device used for diesel engine and based on lower-pressure water evaporation heat absorption

A technology for cooling devices and diesel engines, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve problems such as inability to quickly absorb heat, large cooling water consumption, poor cooling effect, etc., and achieve low boiling point and large latent heat of vaporization , The effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

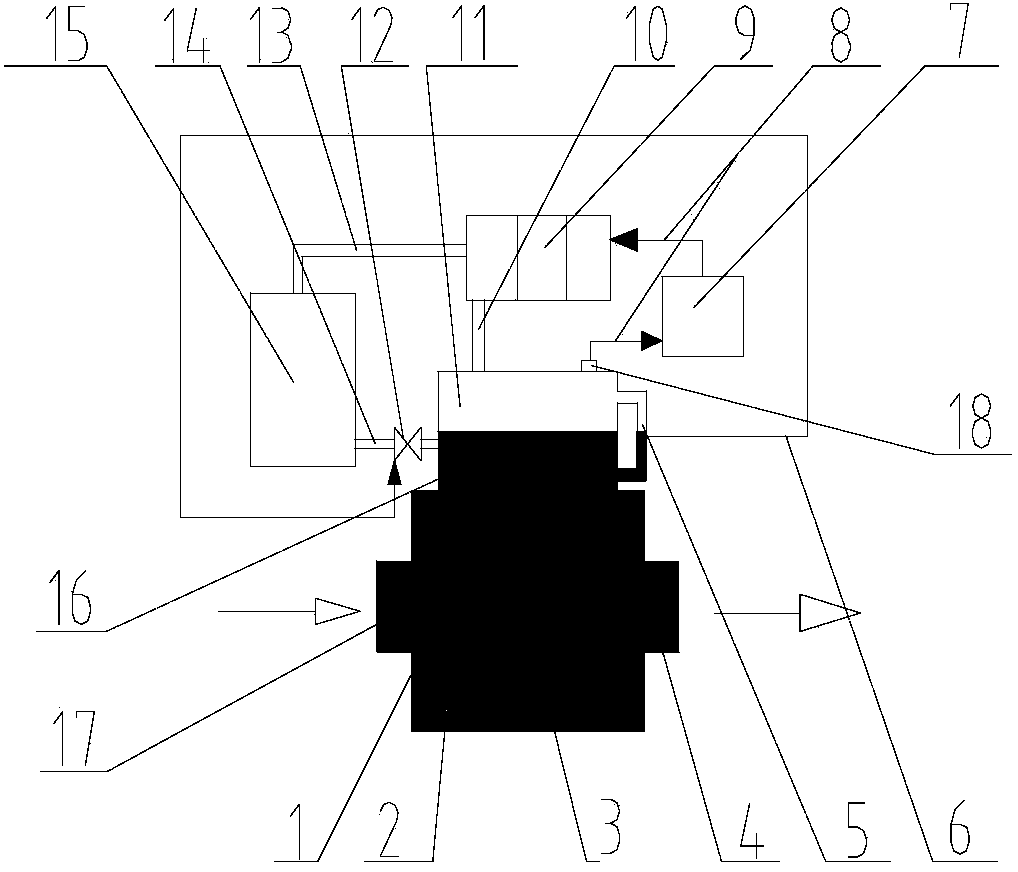

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

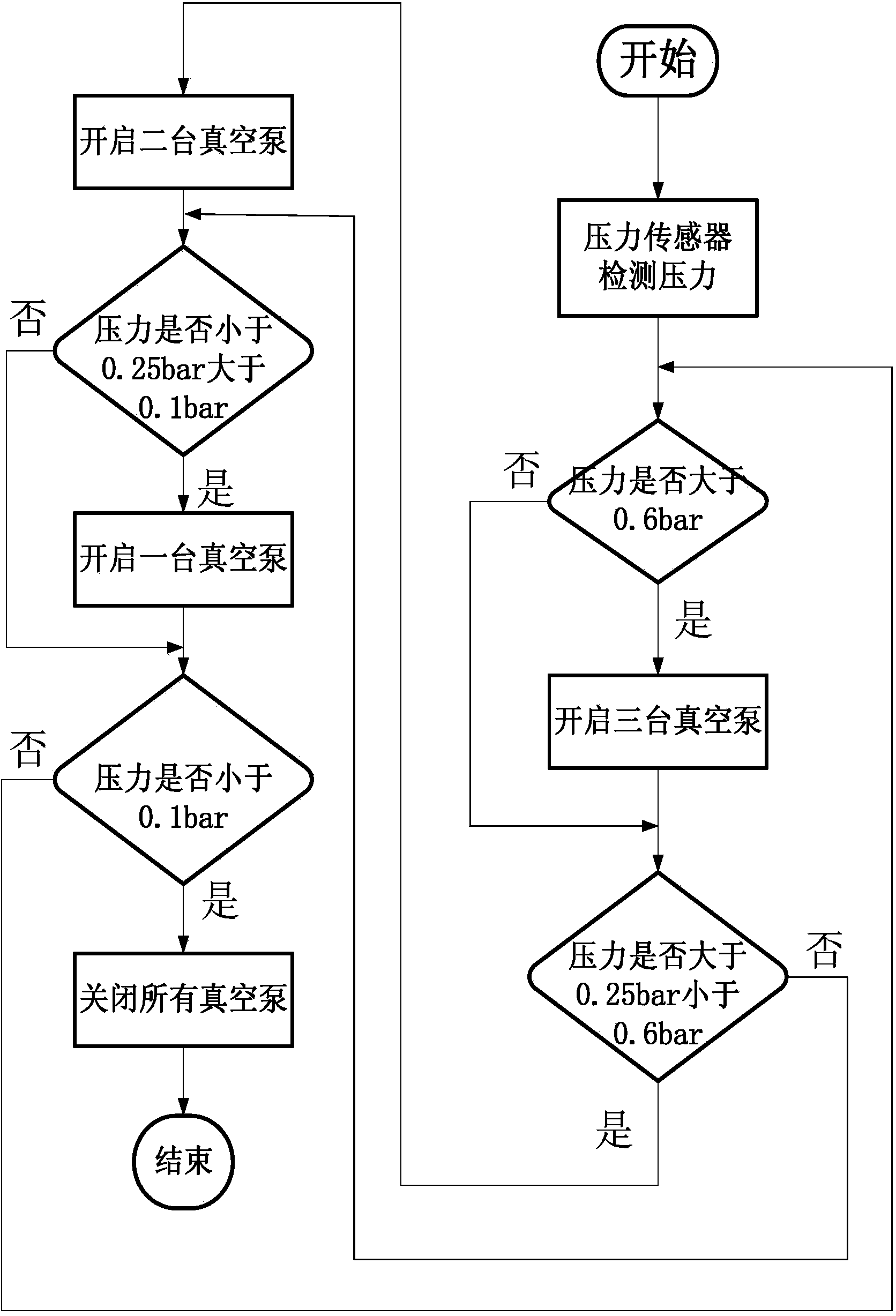

[0013] combine Figure 1~2 , the present invention is based on the low-pressure water vaporization endothermic cooling device for intercooling the intake air of the diesel engine, which consists of a cooler, a suction device, and a return system. The cooler starts from the air inlet 1, and the intake air of the diesel engine enters the cooler from the air inlet after passing through the supercharger, exchanges heat with the cooling jacket 2 and the cooling jacket 3 in the cooler, and then leaves the air outlet 4 for cooling appliances and cooling units. Wherein, the cooling jacket 3 and the cooling jacket 2 are welded together, the low-pressure water in the cooling jacket 3 is not in contact with the intake air, and there is no mass exchange but only heat exchange. The low-pressure water in the cooling jacket 3 comes from the low-pressure water storage tank 11 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap