Control device capable of real time monitoring of extractor hood operating state and control method

A range hood and operating state technology, which is applied in the field of control devices for real-time monitoring of the operating state of the range hood, can solve problems such as inability to eliminate oil fume, heat accumulation, fire, etc., to avoid equipment damage or fire, and the hardware structure is simple and accurate sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

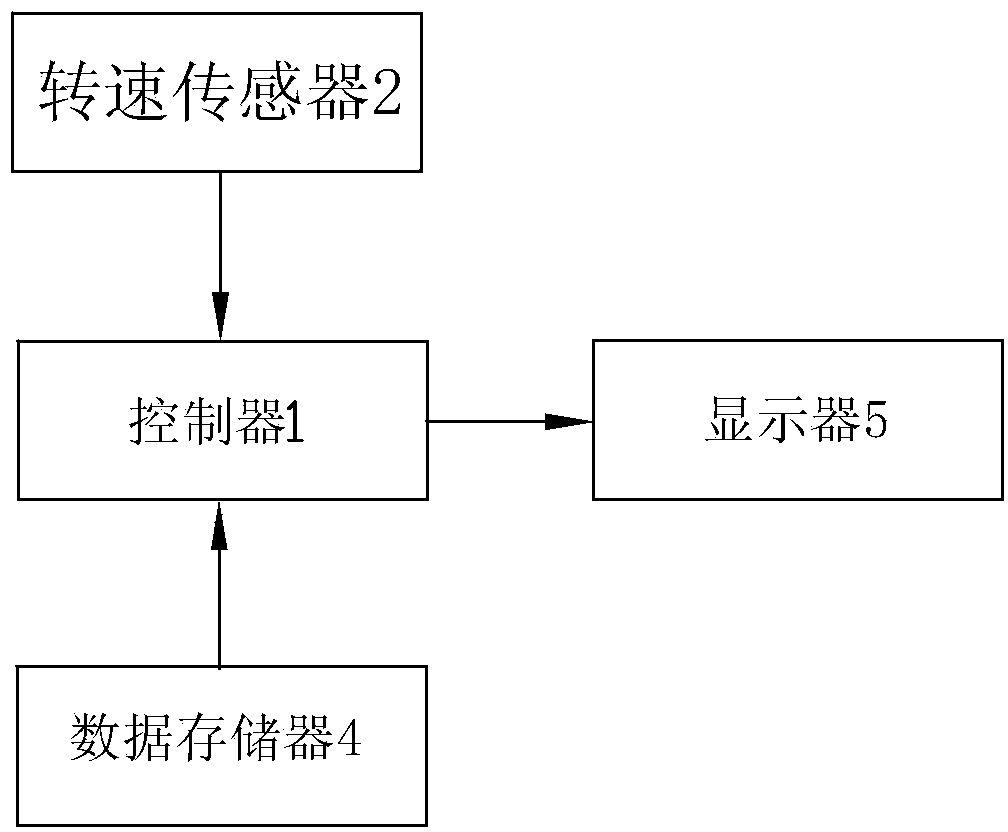

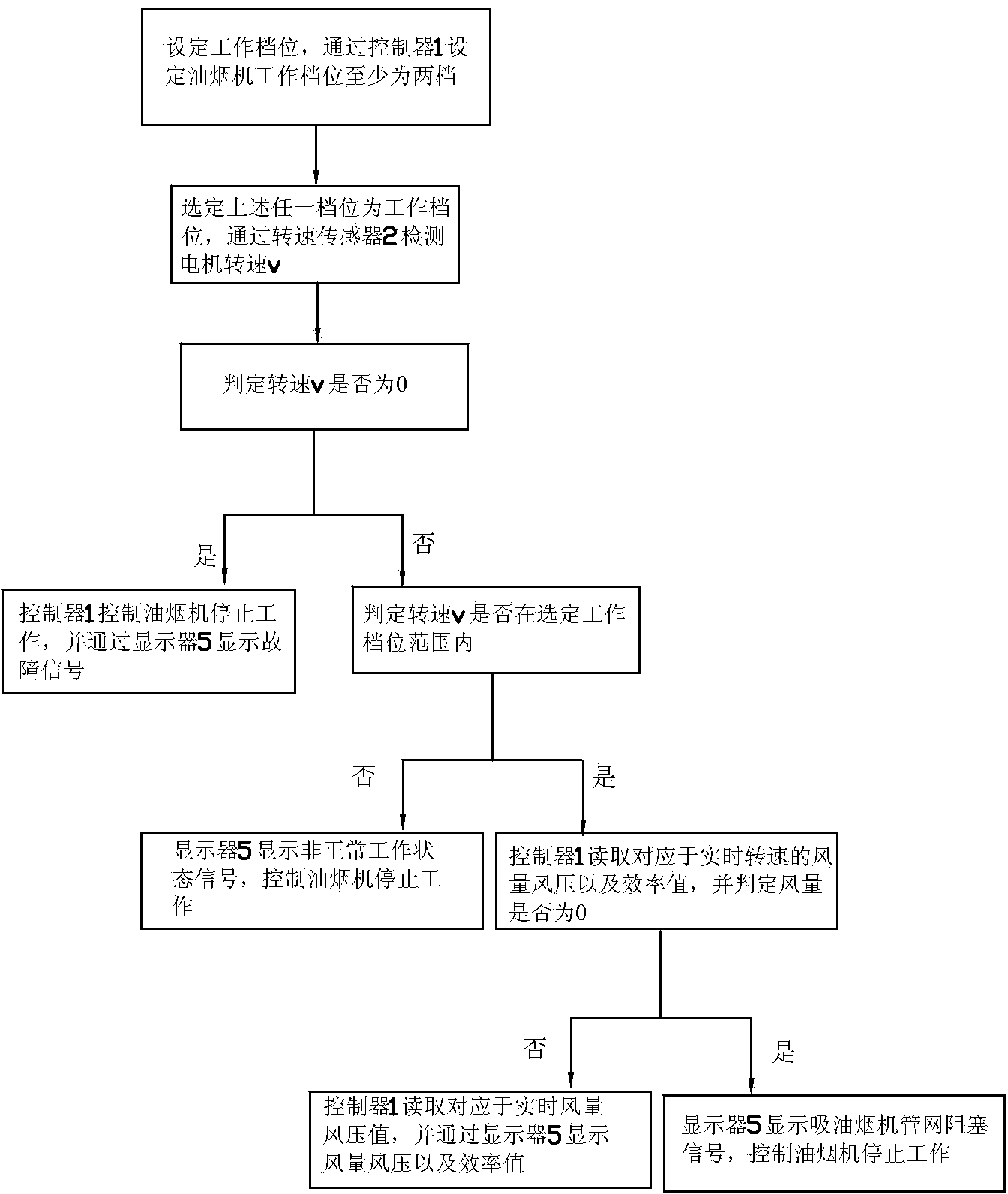

[0049] A control device capable of real-time monitoring of the operating state of a range hood, characterized by comprising a controller 1, wherein the controller 1 has at least two working gears, and the speed range A of the first gear is <A<A2 , the rotational speed range B of the second gear is B1<B<B2, wherein 0 revolutions / second<A1<B1<A2<B2<2000 revolutions / second, and the controller 1 is connected with a rotational speed sensor 2 for detecting the rotational speed of the motor , a data memory 4 for storing air volume and pressure values corresponding to the speed and efficiency value data, a display 5 for displaying air volume and pressure information, and the controller 1 judges whether the motor speed v detected by the speed sensor 2 is in the working gear In the speed range of the speed, when the speed v is within the speed range of the working gear and the air volume is not 0 cubic meters per hour, the air volume, wind pressure and efficiency value are displayed on...

Embodiment 2

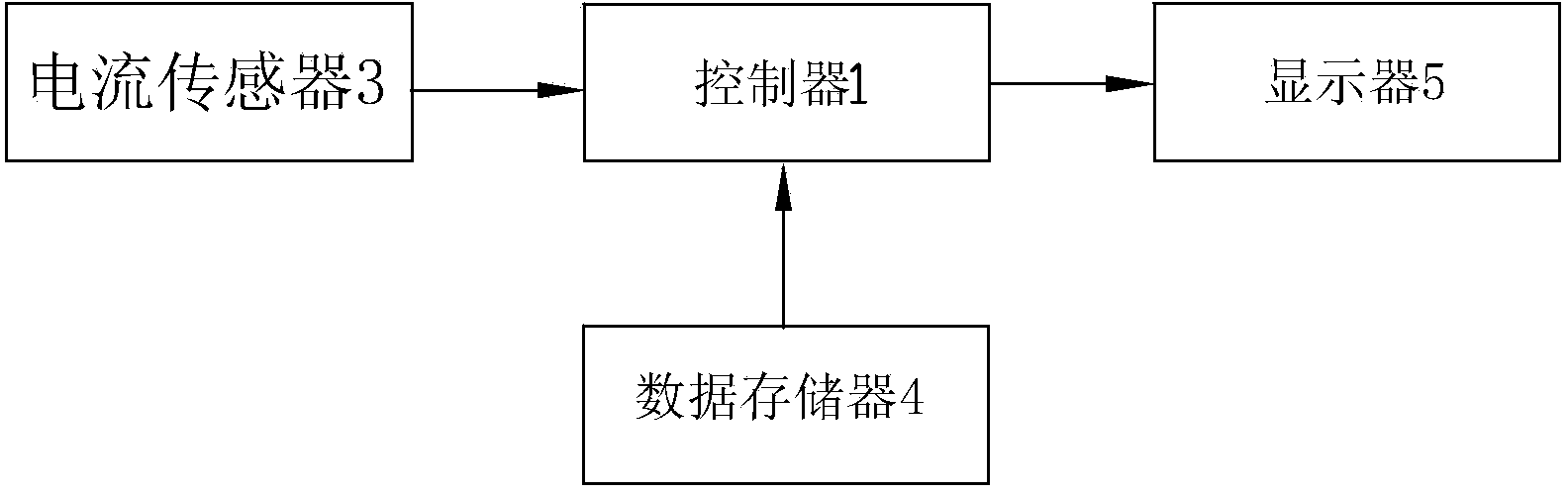

[0062] A control device capable of real-time monitoring of the operating state of a range hood, including a controller 1, the controller 1 has at least two working gears, the current range D of the first gear is D1<D<D2, the second The current range E of the second gear is E1<E<E2, wherein 0A<D1<E1<D2<E2<2A, the controller 1 is connected with a current sensor 3 for detecting the motor current, which is used to store the current corresponding A data memory 4 for air volume, wind pressure and efficiency value data, a display 5 for displaying air volume, wind pressure and efficiency value information, and the controller 1 judges whether the motor current i detected by the current sensor 3 is within the current range of the working gear , when the current i is within the current range of the working gear and the air volume is not 0 cubic meters per hour, the air volume, wind pressure and efficiency values are displayed on the display 5 .

[0063] A control method capable of real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com