A method for performance analysis of LPG storage tank coating protection system under fire environment

A protection system, passive protection system technology, applied in the field of LPG storage tank coating passive protection system, can solve the problems that are rarely reported, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

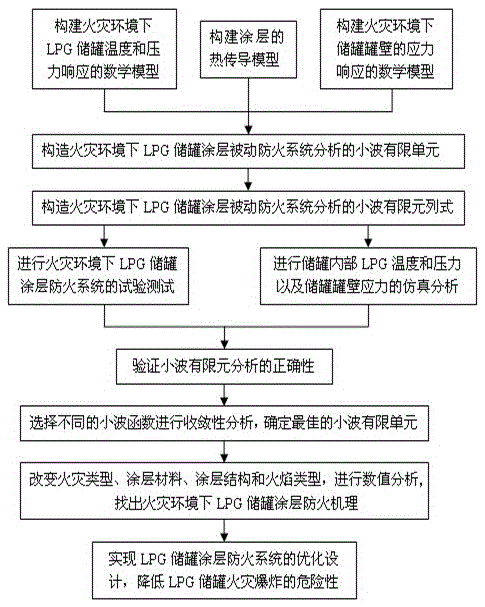

[0023] This study mainly uses the methods of simulation analysis and experimental testing to reveal the passive fire protection mechanism of LPG storage tank coatings under fire conditions.

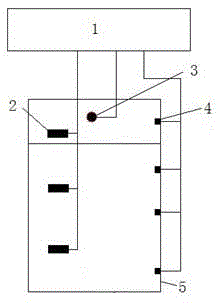

[0024] Step 1: Construct a wavelet finite element model for performance analysis of LPG tank coating passive protection system in fire environment

[0025] (a) Construct the mathematical model corresponding to the temperature and pressure of the LPG storage tank.

[0026] The RNGk-ε model is used to analyze the turbulent flow of LPG in the tank under the fire environment. The turbulent kinetic energy transfer model is as follows:

[0027] ∂ k ∂ t + ∂ ( k u i ) ∂ x i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com