Contactor electromagnetic system

An electromagnetic system and contactor technology, applied in the direction of electromagnetic relays, electromagnetic relay details, circuits, etc., can solve problems such as high production energy consumption, short service life, polluting the environment or poor effect of buffering vibration, etc., to achieve good buffering The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

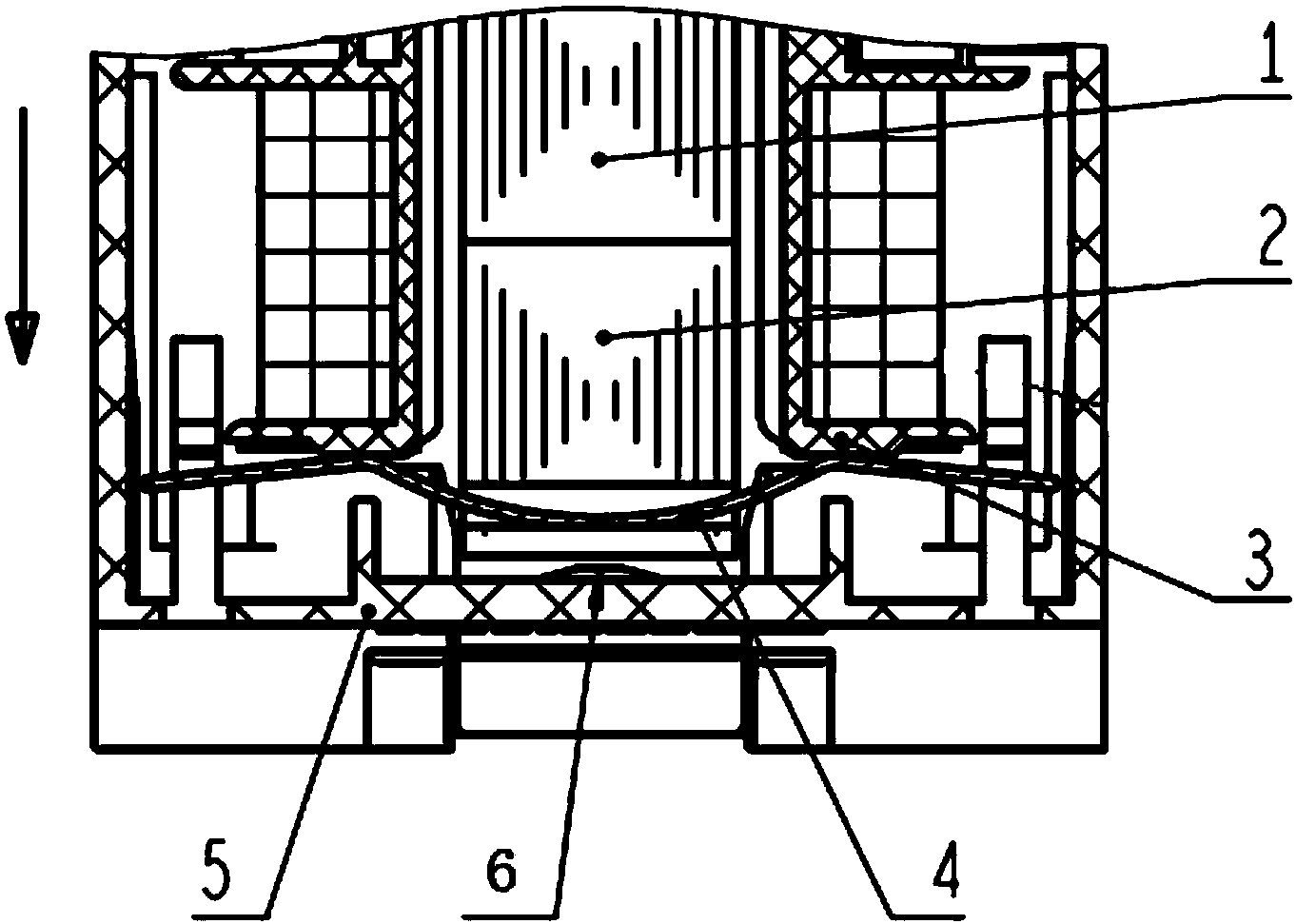

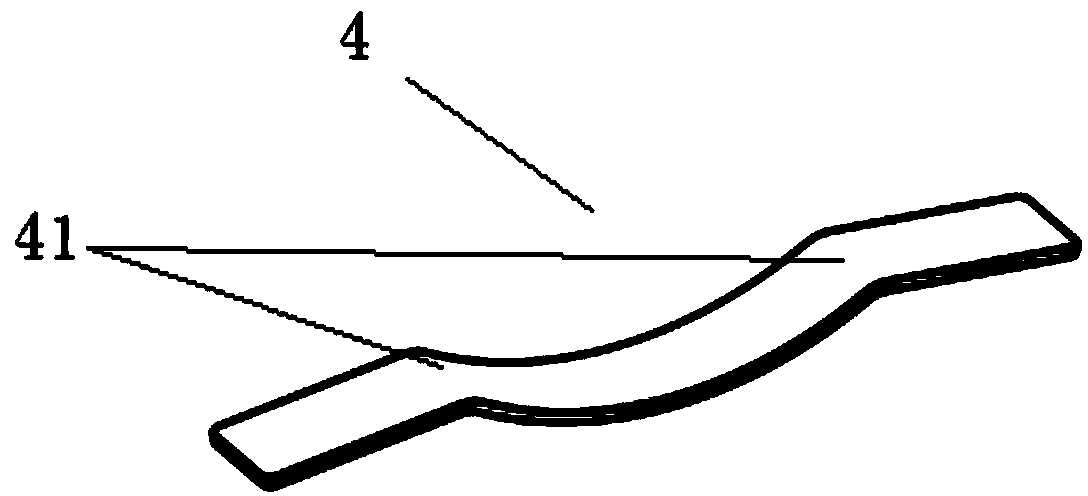

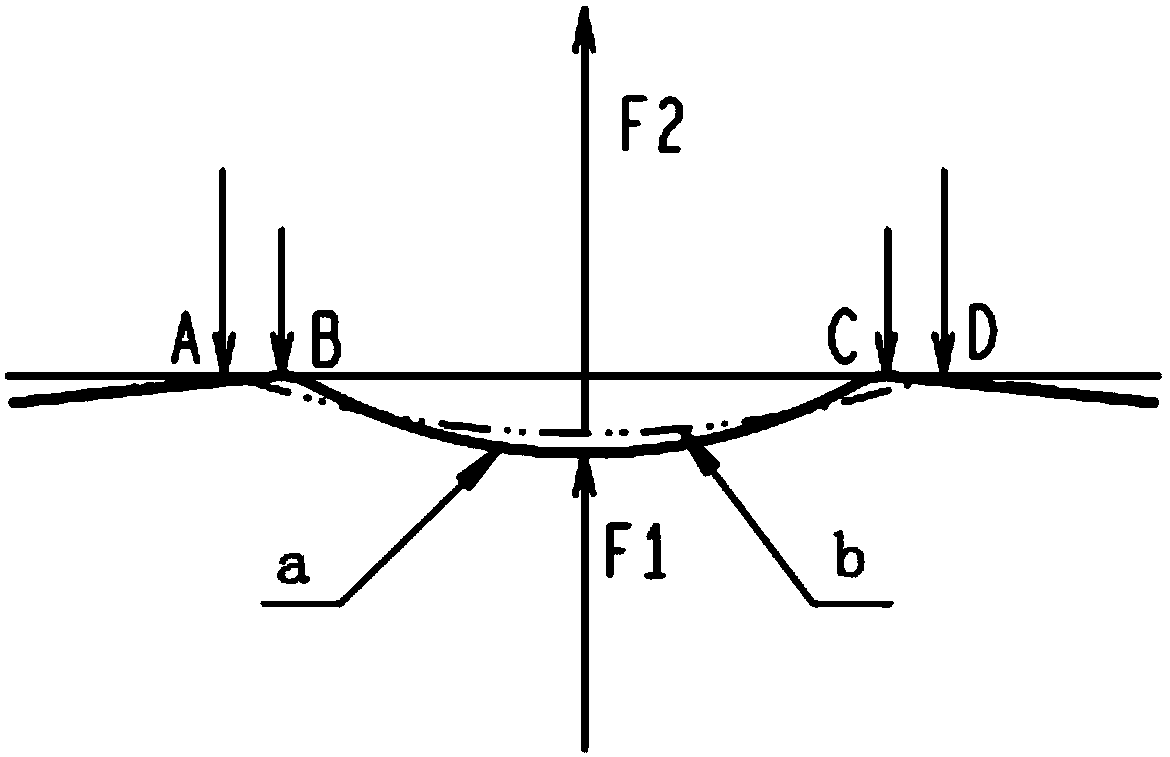

[0046] Such as figure 1 As shown, this embodiment provides a contactor electromagnetic system, including a base 5, a coil 3 disposed inside the base 5, a yoke 2, an armature 1, and an elastic buffer between the coil 3 and the base 5, and the coil is energized , a strong electromagnetic force is generated between the yoke 2 and the armature 1, and under the action of the electromagnetic force, the armature 1 and the yoke 2 are combined into one body and then move along the axial direction of the coil 3 hit the base, the elastic buffer buffers the vibration generated after the armature 1 and the yoke 2 hit the base 5; Vibration has a good buffering effect and will not cause a lot of pollution in the production process, such as figure 1 As shown, the yoke 2 of this embodiment is formed with installation holes penetrating from its two side walls, and the extension direction of the installation hole 21 is perpendicular to the axial direction of the coil 3, so that the extension ...

Embodiment 2

[0065] This embodiment provides a contactor electromagnetic system, which is a modification of Embodiment 1. The mounting holes 21 in this embodiment are formed into two, and are respectively formed between two adjacent vertical portions 23 On the horizontal part 22 between, the size of the two installation holes 21 is the same, and each of the installation holes 21 is inserted with the leaf spring 4 as described in the first embodiment.

Embodiment 3

[0067] This embodiment provides a contactor electromagnetic system, which is a modification of Embodiment 1 and Embodiment 2. In this embodiment, both ends of the leaf spring 4 are fixed relative to the base 5 .

[0068] Specifically, both ends of the leaf spring 4 are respectively fixed on the ends of the coil 3 that are opposite to the side wall of the base 5 that is hit.

[0069] As a modification of fixing the two ends of the leaf spring 4, the two ends of the leaf spring 4 in this embodiment can also be fixed on the two side walls of the base 5, or the base 5 The two ends of the leaf spring 4 corresponding to the impacted side walls are respectively formed with bosses protruding towards the two ends of the leaf spring 4, and the two ends of the leaf spring 4 can be fixed on the two ends of the leaf spring 4. on the boss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com