Double stator high power density flux switching permanent magnet motor

A technology of high power density and magnetic flux switching, applied in motors, electric vehicles, electrical components, etc., can solve the problems of difficult installation of permanent magnets, difficult heat dissipation of permanent magnets, and poor structural reliability, so as to reduce the risk of irreversible demagnetization and reduce costs. and weight, benefits for production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

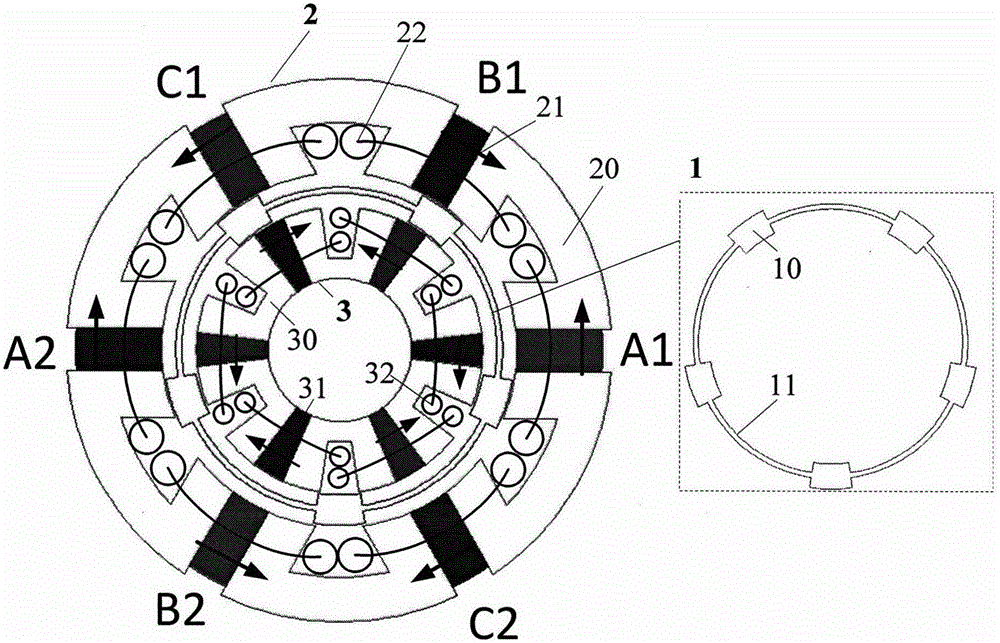

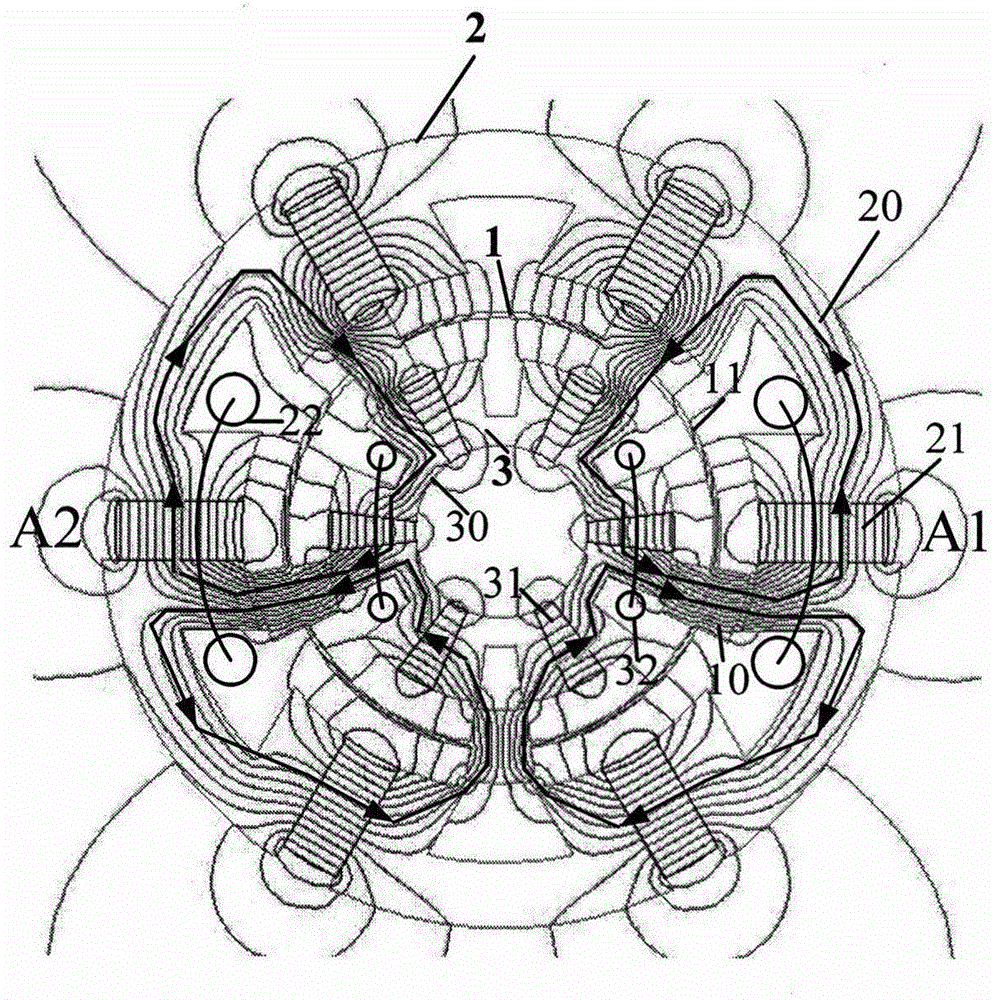

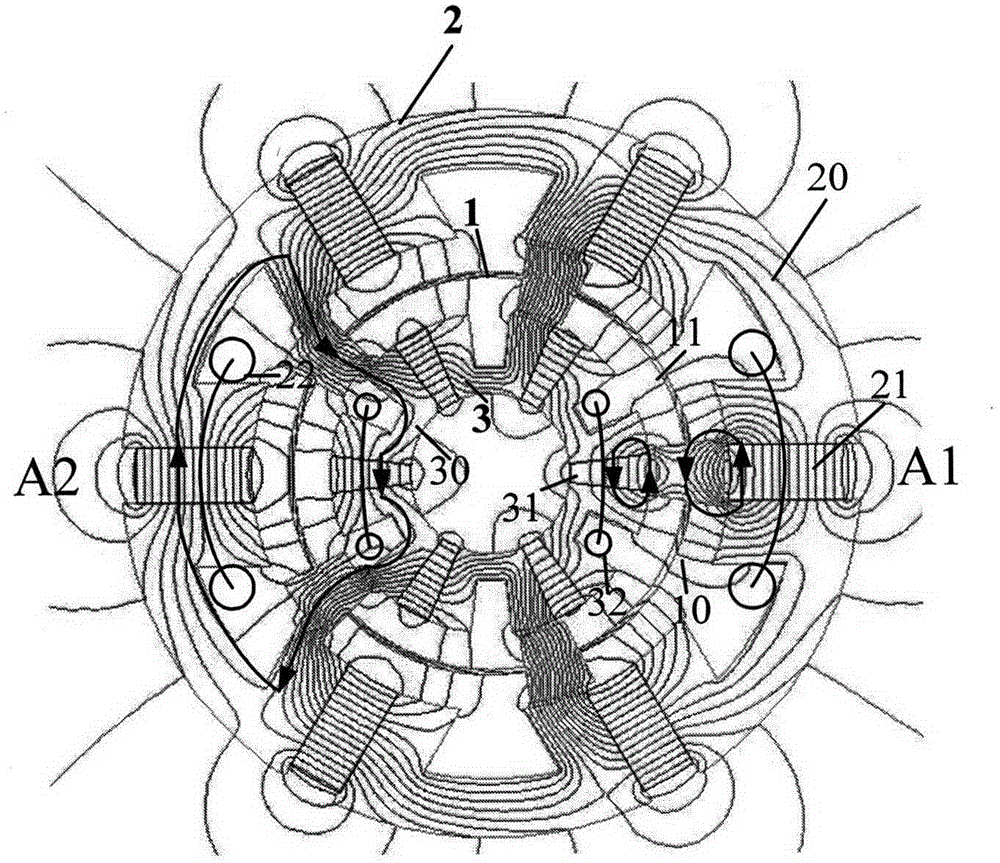

[0028] Such as figure 1 As shown, the present invention includes a double-sided stator and a rotor, with an air gap between the rotor 1 and the outer stator 2 and inner stator 3 . The outer stator 2 includes 2km=6 U-shaped magnetic permeable blocks 20, 2km=6 permanent magnets 21 and 2km=6 sets of concentrated windings 22, k=1, m=3 are all positive integers, and m represents the number of motor phases. The embodiment is a three-phase motor; each permanent magnet 21 is sandwiched between two adjacent U-shaped magnetic blocks 20, and the concentrated winding 22 is arranged in the groove of the U-shaped magnetic block and encases the permanent magnets 21; adjacent permanent magnets The magnets are alternately magnetized tangentially. The inner stator 3 also includes 6 U-shaped magnetic blocks 30, 6 permanent magnets 31 and 6 sets of concentrated windings 32. The radial axes of the inner stator 3 and the magnetic blocks of the outer stator 2 coincide with each other, and the magne...

Embodiment 2

[0034] Figure 4 It is a three-phase double-stator high power density flux switching permanent magnet motor. The outer stator 2 of the present embodiment comprises 2km=12 pieces of U-shaped magnetic permeable blocks 20, 2km=12 pieces of permanent magnets 21 and 2km=12 sets of concentrated windings 22, get k=2, m=3, because the rotor magnetic permeable blocks 10 The number Nr=2km±n (n / m is not an integer), when n=1 and 2, Nr can be 10,11,13,14, and present embodiment gets Nr=2km+n=14 (n= 2), m represents the number of motor phases, and this embodiment is also a three-phase motor; each phase winding in the outer stator 2 in this embodiment is composed of four concentrated windings A1, A2, A3 and A4 connected in series or in parallel. The relative positions of concentrated windings A1 and A3 to rotor 1 are the same, and the relative positions of A2 and A4 to rotor 1 are also the same, but the relative positions of A1 and A3 and A2 and A4 to rotor 1 differ from each other by half...

Embodiment 3

[0036] Figure 5 Also for a three-phase dual-stator high power density flux switching permanent magnet motor. The difference between this embodiment and the motor of Embodiment 2 is that the number of magnetic conductive blocks of the rotor 1 is Nr=2km+n=13 (n=1), k=2, m=3, and this embodiment is also a three-phase motor. Each phase winding in the outer stator 2 is composed of four concentrated windings A1, A2, A3 and A4 connected in series or in parallel. The relative positions of concentrated windings A1 and A3 and the rotor differ by half a rotor 1 pole pitch, and the relative positions of A2 and A4 and the rotor also differ by half a rotor 1 pole pitch, but the relative positions of A1 and A3 and A2 and A4 and rotor 1 The positions are relatively close. When the concentrated windings A1, A2, A3 and A4 are connected in series to form the A-phase winding, the amplitude of the back EMF of the A-phase winding is slightly less than four times the fundamental amplitude of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com