Brushless DC (direct current) motor 180-degree square wave control method and module and converter

A technology of brushed DC motor and control method, which is applied in the direction of AC motor control, single motor speed/torque control, control system, etc., can solve the problem that SVPWM modulation cannot be used, and achieve the effect of reducing current harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

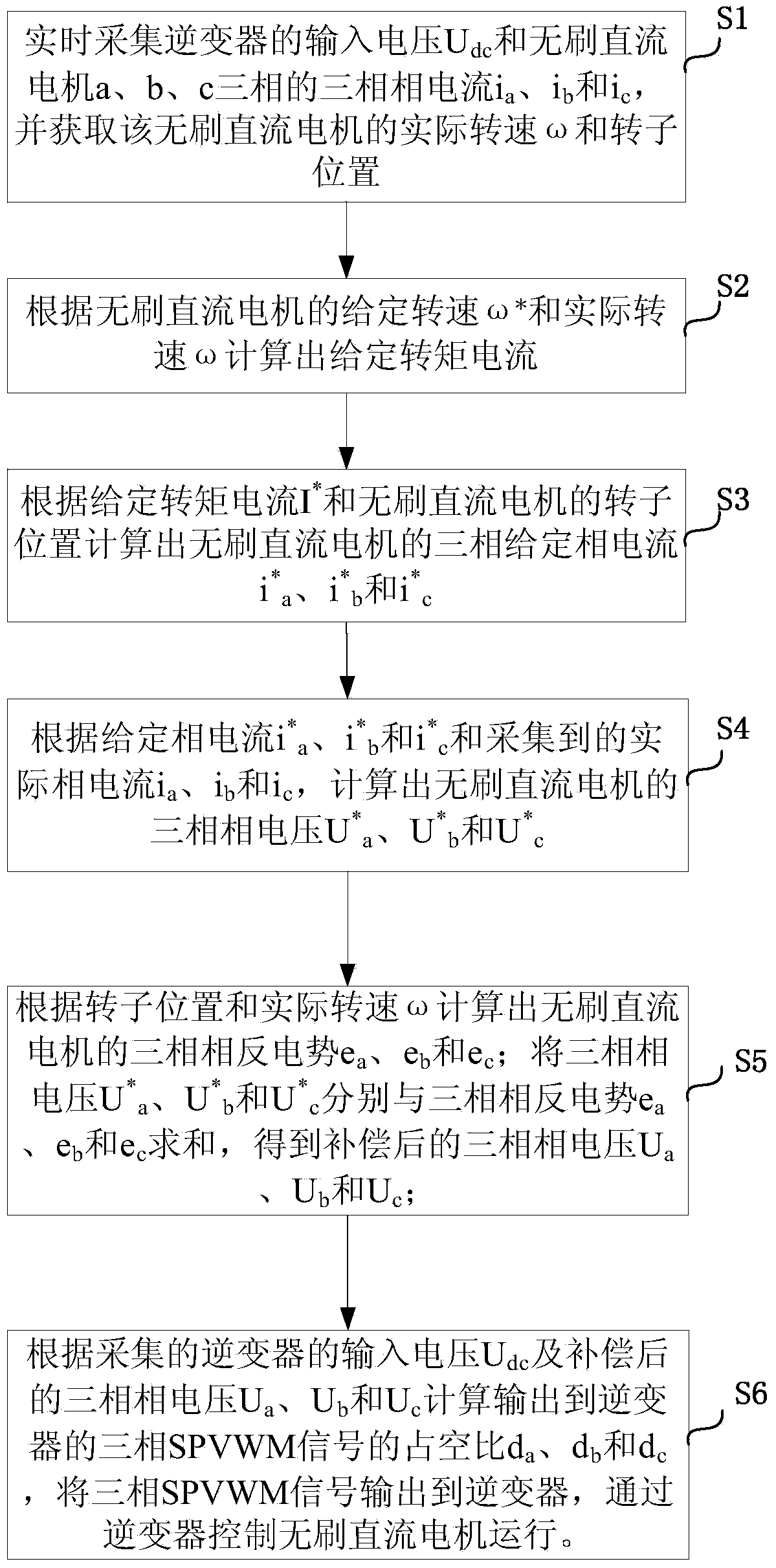

[0028] see figure 1 . A 180° square wave control method for a brushless DC motor according to an embodiment of the present invention includes the following steps:

[0029] Step S1: collect and control the input voltage U of the inverter of the brushless DC motor in real time dc and the three-phase phase current i of the brushless DC motor a, b, c three-phase a i b and i c , and obtain the actual speed ω and rotor position of the brushless DC motor.

[0030] Among them, the input voltage U dc , phase current i a i b and i c Sampling can be done using a sampling resistor or other sensor. The rotational speed can be measured by sensors such as encoders, or can be estimated based on voltage and current. There are also many ways to obtain the rotor position. For example, the continuous rotor position can be obtained by sensors such as absolute encoders, or the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com