Vacuum film formation device

A film forming device and vacuum technology, which are applied in vacuum evaporation plating, ion implantation plating, gaseous chemical plating, etc., can solve the problems of reduced film forming speed, difficulty in controlling the position of arc discharge arc, and reduced productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0033] [the whole frame]

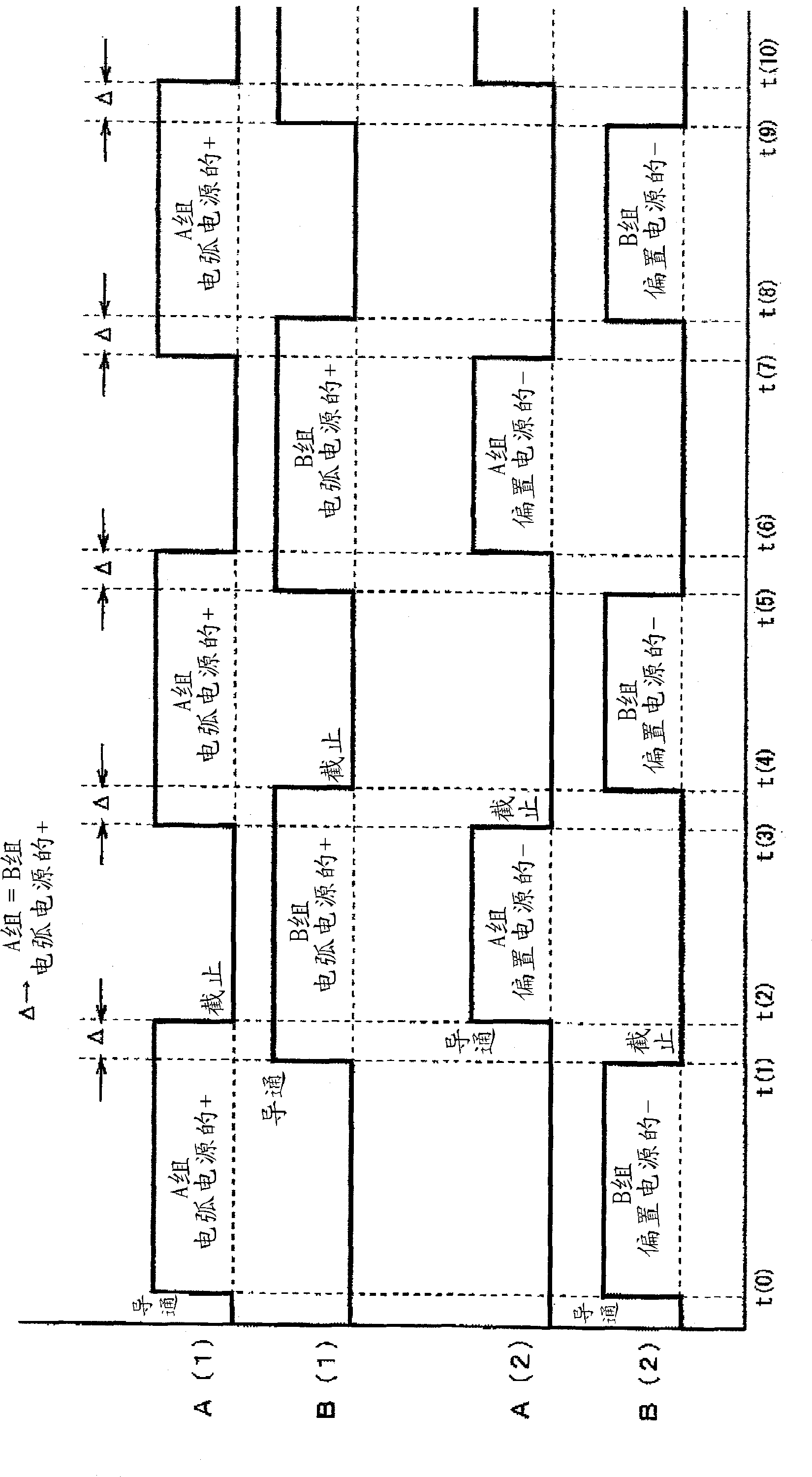

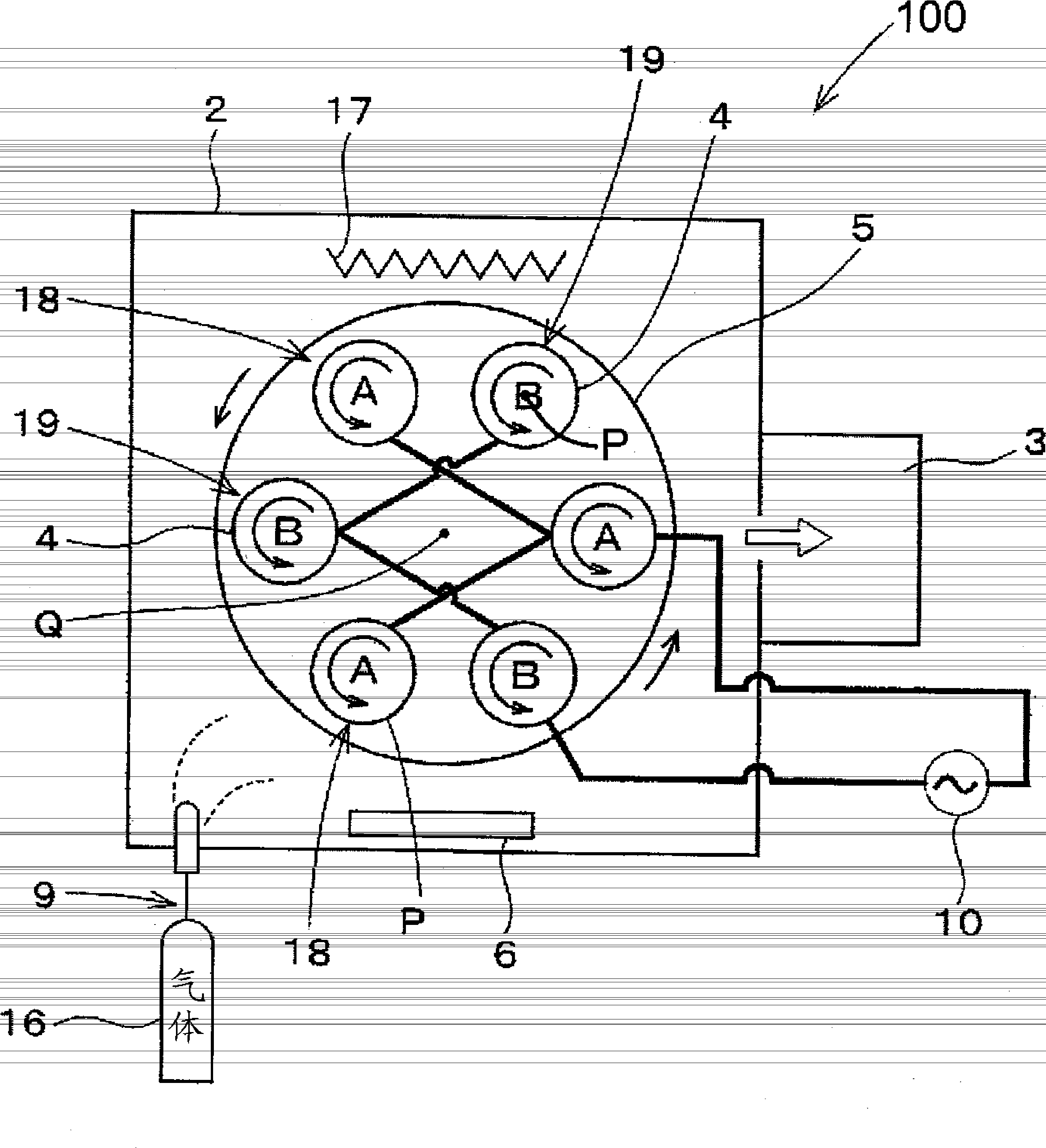

[0034] figure 1 The overall structure of a plasma CVD apparatus 100 as an example of the vacuum film forming apparatus of the present invention is shown. figure 2 This is an example of power connection of the plasma CVD apparatus 100 .

[0035] This plasma CVD apparatus 100 has a vacuum chamber 2 , a vacuum evacuation unit 3 , and a plurality of rotation holding units 4 . The evacuation unit 3 evacuates the inside of the vacuum chamber 2 . Each rotation holding unit 4 holds the substrate W to be film-formed. In addition, each rotation holder 4 rotates while holding the base material W. As shown in FIG. These plurality of rotation holders 4 are provided on the revolution table 5 so that the rotation axes of the respective rotation holders 4 are parallel to each other. This plasma CVD apparatus 100 includes a revolution mechanism 8 . This revolution mechanism 8 revolves the revolution table 5 provided with the plurality of rotation holding parts...

no. 2 approach

[0093] [the whole frame]

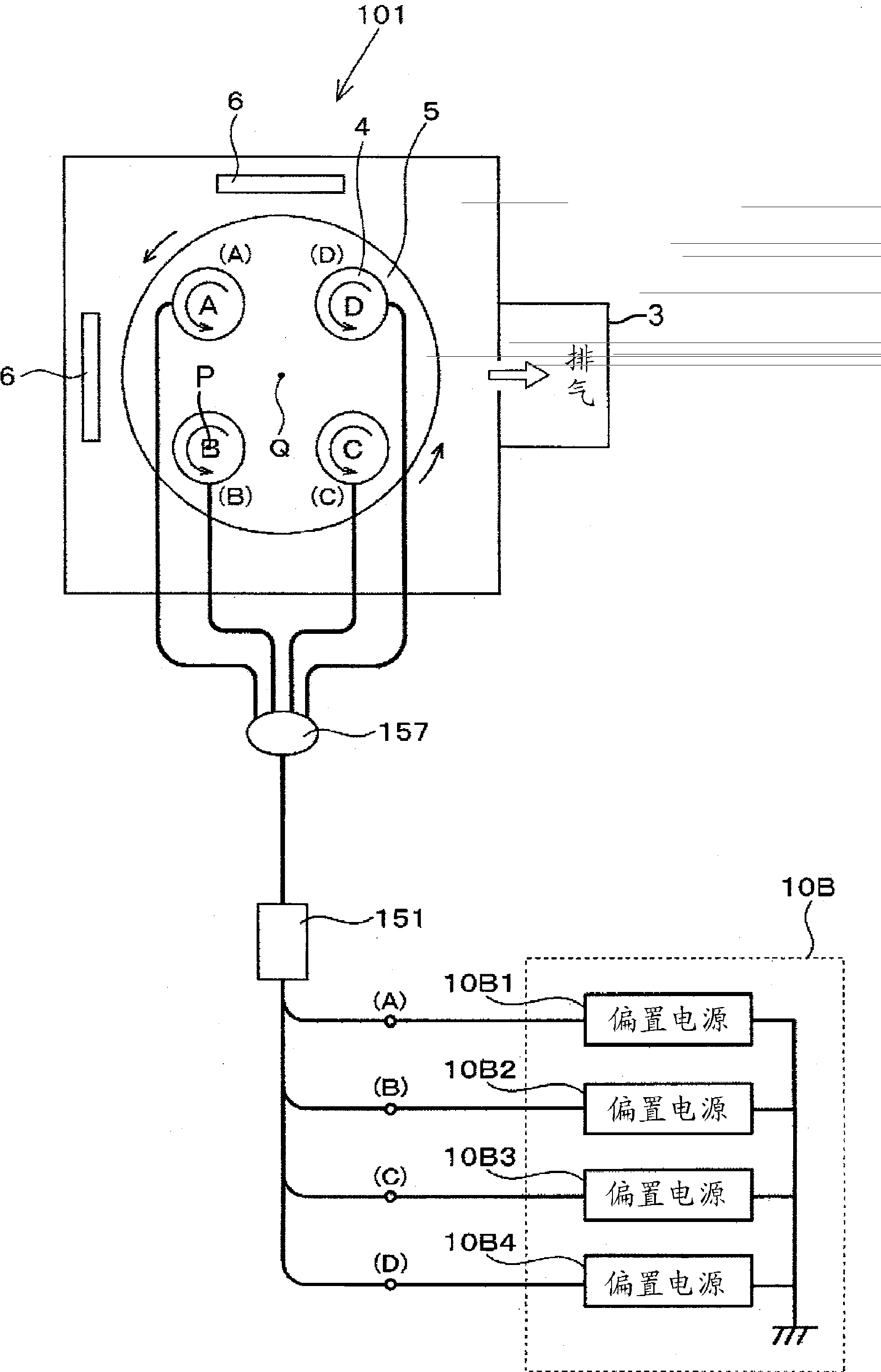

[0094] As follows, while referring to Figure 6 An AIP (Arc Ion Plating) apparatus as an example of the vacuum film forming apparatus of the present invention will be described. Also, since using image 3 (a) ~ Figure 4 The description given is the same as that of the first embodiment, so it will not be repeated here. In addition, the overall structure of the AIP device 101 is the same as that of the figure 1 same.

[0095] The AIP device 101 is equipped with an evaporation source 6 (herein an arc evaporation source: refer to Figure 7 ) and a power supply unit 10A having a plurality of outputs capable of supplying (applying) bias voltages to the respective rotation holding portions 4 so that the respective rotation holding portions 4 have potentials different from each other. This AIP apparatus 101 forms a film on the base material W held in each rotation holding part 4 in the same manner as in the first embodiment using the AIP method.

[0...

no. 3 approach

[0126] Hereinafter, the AIP apparatus 102 which is an example of the vacuum film-forming apparatus of this invention is demonstrated. Also, since using image 3 (a)~ Figure 4 The description is the same as that of the first embodiment, so it will not be repeated here. In addition, the overall structure of the AIP device 102 is the same as that of the figure 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com