Tape casting membrane preparation production line

A technology of production line and casting method, which is applied in the field of film production line by casting method, which can solve the problems of difficult thickness reduction and poor film uniformity, and achieve the effects of reducing occupied space, high film production efficiency and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

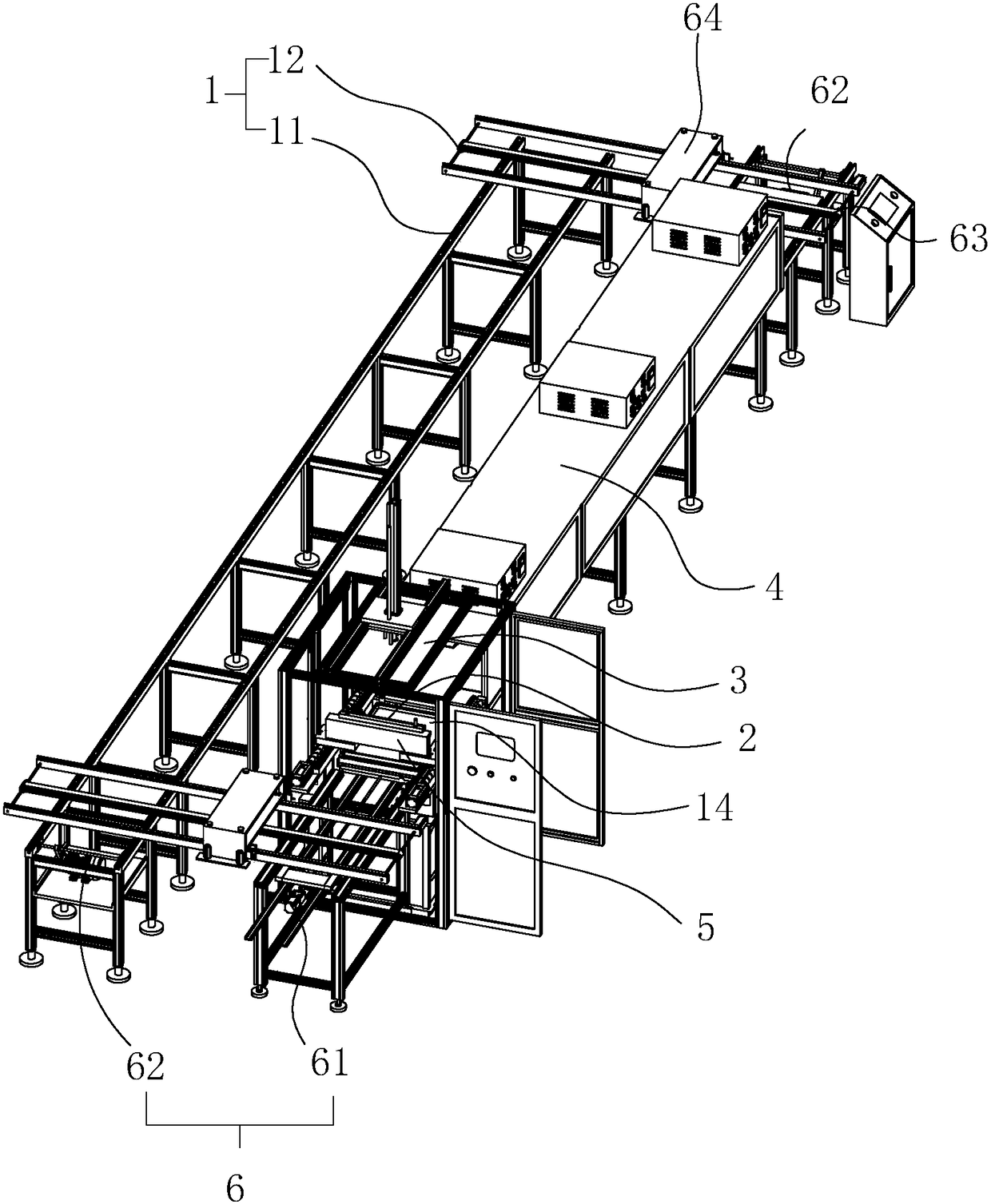

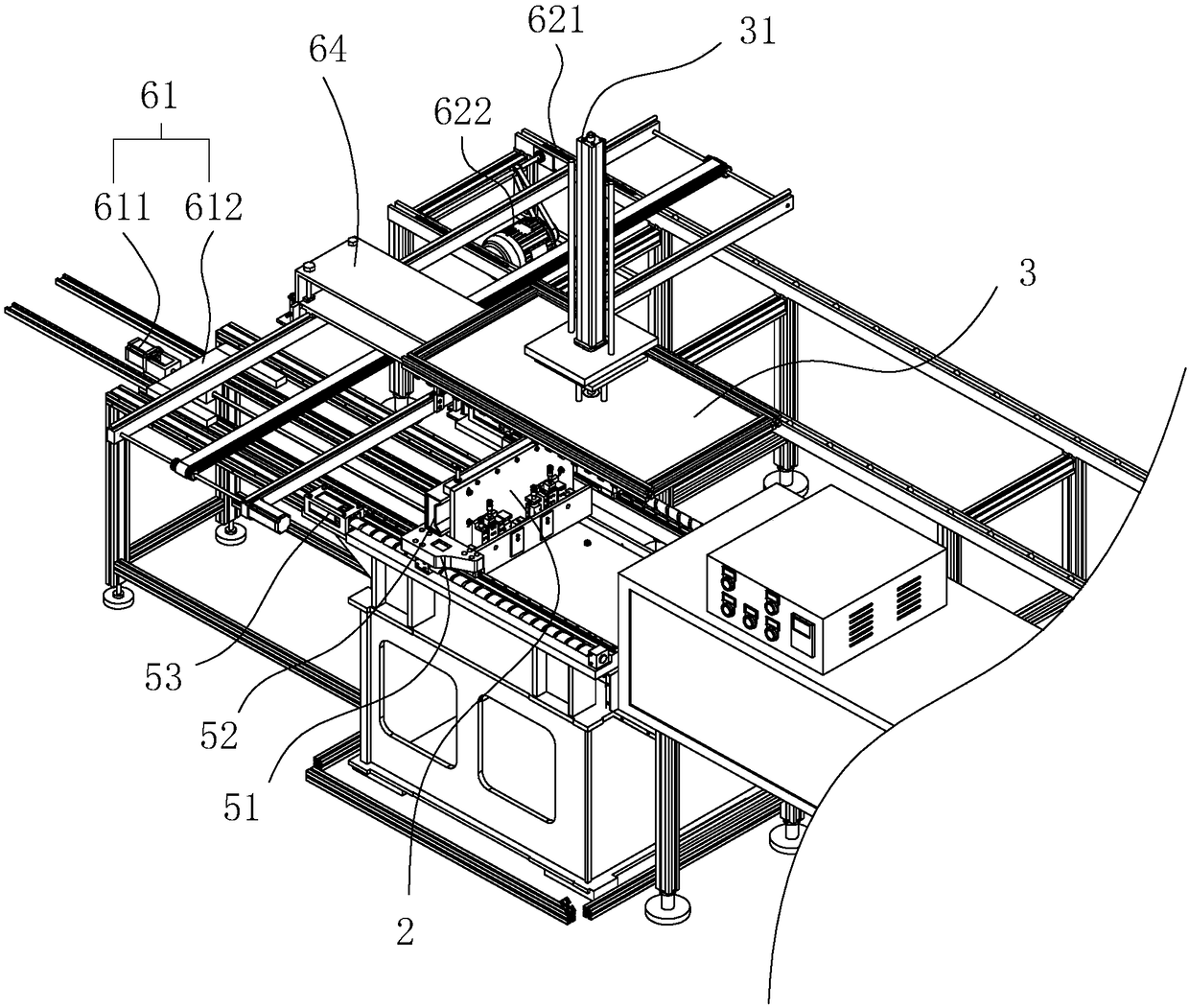

[0044] Embodiment 1: a kind of cast method film production line, such as figure 1 As shown, a frame 1 is included, and the frame 1 includes two transverse rails 11 and two longitudinal rails 12 connected to adjacent transverse rails 11, the longitudinal rails 12 are higher than the transverse rails 11 and part of the longitudinal rails 12 overlap with the transverse rails 11 above.

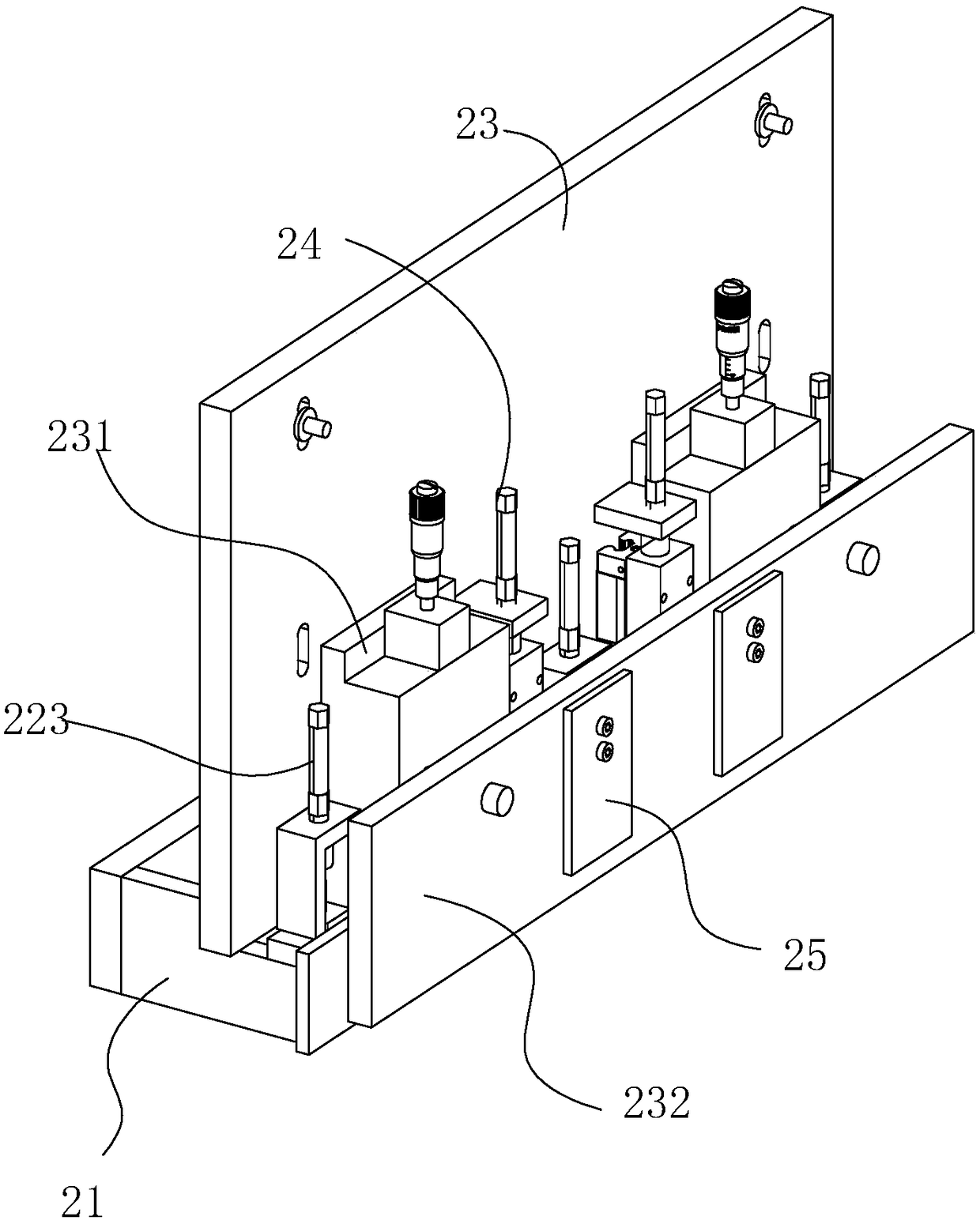

[0045] The horizontal track 11 is provided with a hard film-making plate, a carrying platform for carrying the film-making plate, a coating mechanism 2 for coating the film-forming solution on the film-making plate, a pre-baking mechanism 3 located above the carrying platform, and a driving pre-drying mechanism. The drying mechanism 3 lifts the first lifting assembly 31 and the oven 4 located downstream of the carrying platform. Wherein the film-making plate is generally glass, the coating mechanism 2 is arranged above the carrying platform, and the frame 1 is provided with a coating power mechan...

Embodiment 2

[0069] Embodiment 2: as Figure 9 As shown, the difference from Embodiment 1 is that the valve 22 also includes a second valve plate 225 that slides along the surface of the partition plate 215 to cover the connecting hole 2151 and is fixed on the base 21 to drive the second valve plate 225 moves the second push cylinder 22624.

[0070] The second valve plate 225 and the first valve plate 222 both can complete the opening and closing action at the same time, and can also complete the opening and closing action respectively; The amount of solution can be kept at a constant liquid level at the bottom, and can also be kept at a constant flow rate; quantitative coating can be completed when they are respectively opened and closed, that is, when the liquid outlet 216 is closed, the solution begins to accumulate in the casting tank 218, Then close the connection hole 2151 when coating.

Embodiment 3

[0071] Embodiment 3: as Figure 10 As shown, the difference from Embodiment 1 or 2 is that the end plate 214 abuts and closes with the bottom plate 211, the end plate 214 is lower than the other side walls of other casting grooves 218, and the ends of the end plates 214 are respectively provided with Inclined inner guide surface and outer guide surface; when closed, the end of the first valve plate 222 abuts against the inner guide surface and the outer guide surface at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com