Method for producing a cylinder liner surface and cylinder liner

A cylinder liner and working surface technology, applied in the direction of cylinder, cylinder head, metal material coating process, etc., can solve the problems of material cost, manufacturing process cost disadvantage and influence, and achieve the effect of less coating material consumption and effective protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below.

[0018] According to the invention, the inner surface of the cylinder liner is machined from a commercially available cast iron material. For this purpose, the internal bore is firstly drilled in a known manner by means of a drilling tool. For this purpose, defined dimensions, defined cylindricity and roughness are provided for the inside diameter. This prepares the inner surface of the cylinder liner for the subsequent process steps.

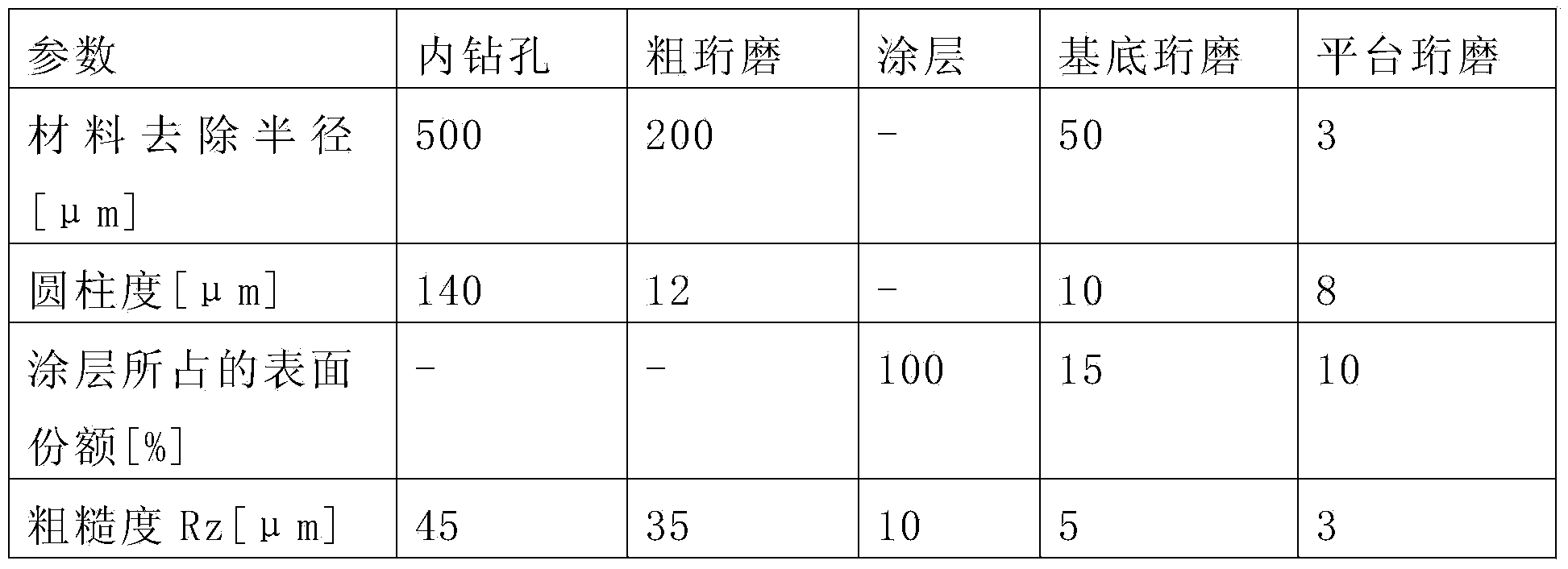

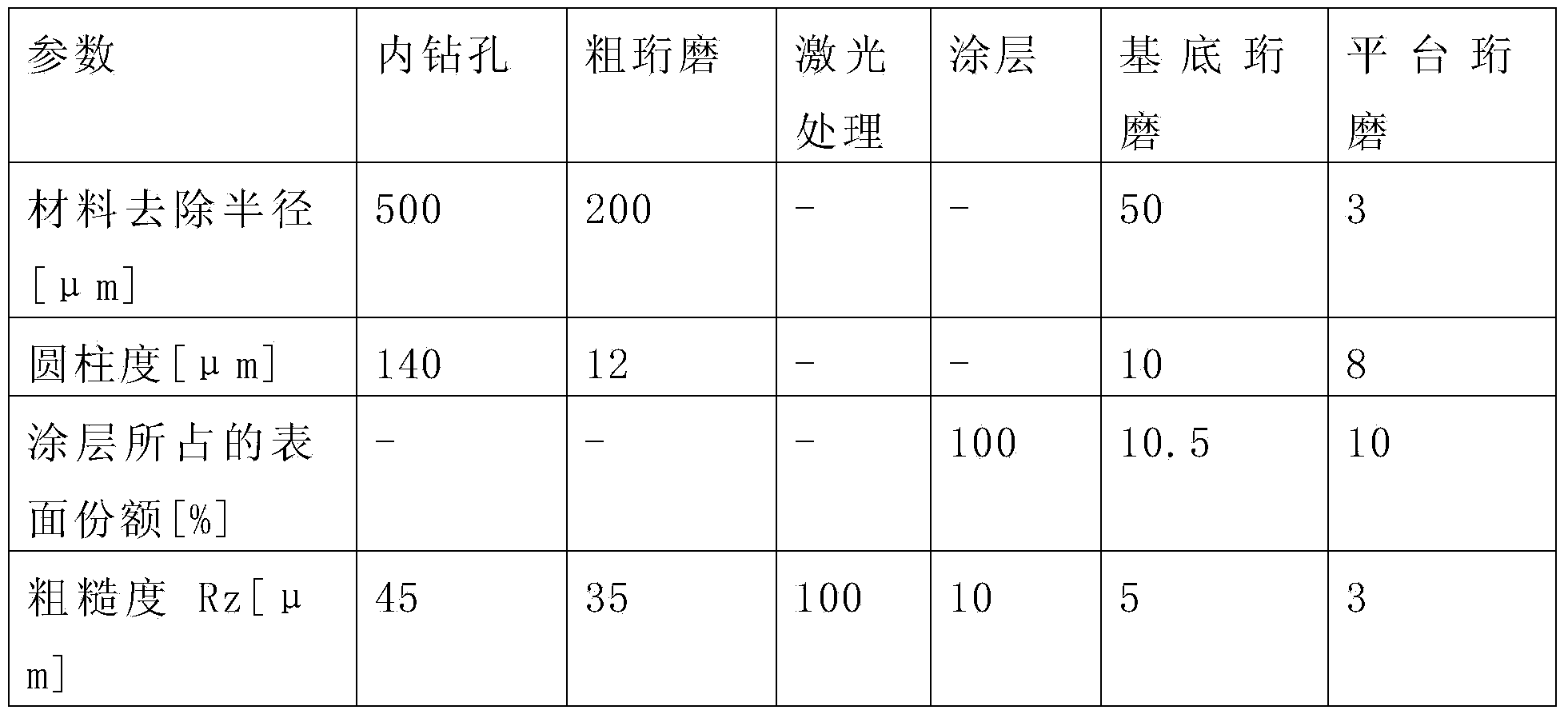

[0019] In a subsequent process step, the inner surface of the cylinder liner is machined by rough honing using a honing tool, the honing stones of the honing tool grinding away material from the inner surface of the cylinder liner. This improves the accuracy of the inner diameter in terms of size, cylindricity and roughness. At the same time, defined depressions (“honing grooves”) are introduced into the inner surface of the cylinder liner. The number, depth and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com