Dispersing head for silicone adhesive high-speed dispersing machine

A technology of high-speed dispersing machine and dispersing head, which is applied to mixers, mixer accessories, dissolving, etc., can solve the problems of less than 50% of high-quality product rate, increase of high-speed shaft resistance, waste of power and manpower, etc., to reduce glue production time, Reduced resistance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

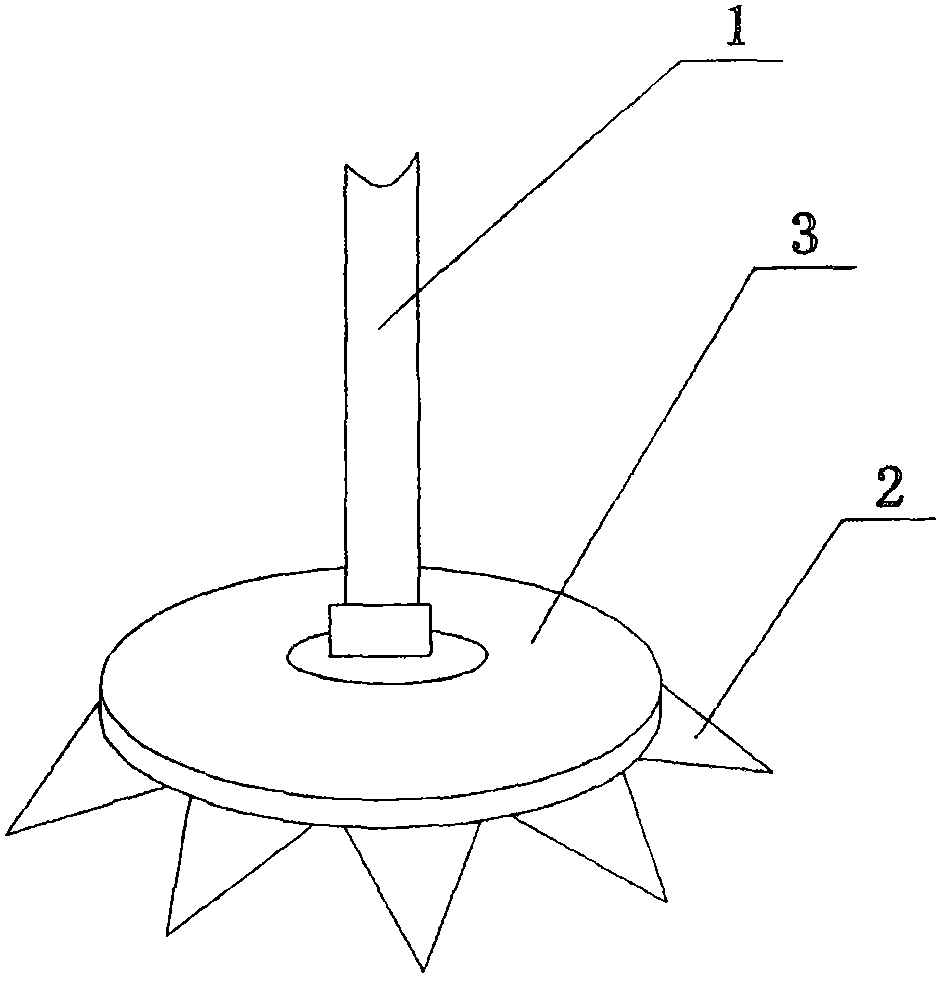

[0014] Example 1: see figure 1 As shown, a dispersing head for a silicone rubber high-speed dispersing machine includes a dispersing shaft 1, a disc 3, and a stirring tooth 2. The dispersing shaft is fixedly installed in the center of the disc, and a row of evenly arranged Stirring teeth, the disc is a hollow structure.

[0015] The stirring teeth are zigzag and evenly arranged on the edge of the disc.

Embodiment 2

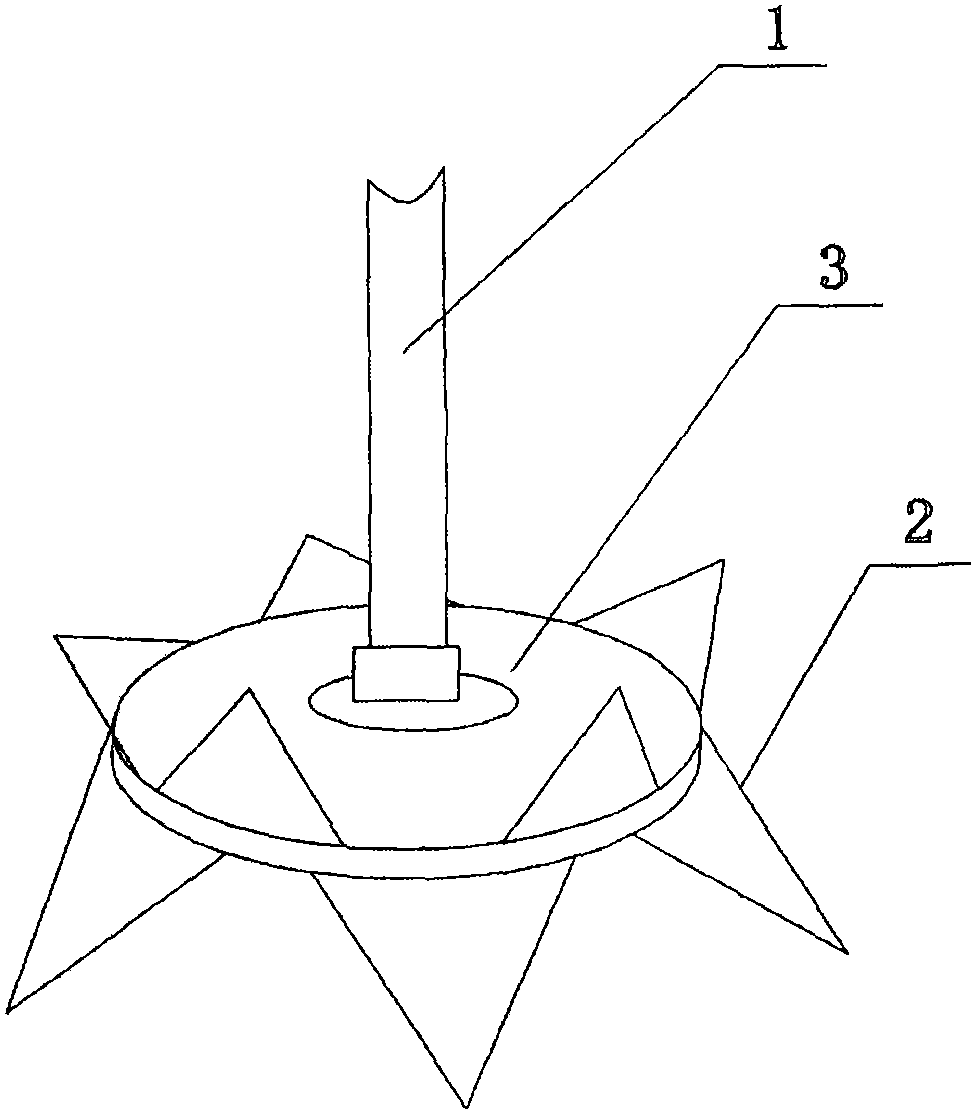

[0016] Example 2: see figure 2 As shown, the meanings represented by the symbols in the figure are the same as those represented in Embodiment 1, and the same parts as in Embodiment 1 will not be repeated. The upper edge and the lower edge of the disc, and the upper and lower layers of stirring teeth respectively form an included angle of 45°-60° with the horizontal plane.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap