Collophanite reverse flotation collecting agent and preparation method thereof

A technology of reverse flotation and collector, applied in flotation, solid separation and other directions, can solve the problems of difficult addition, poor fluidity, low freezing point, etc., to improve yield and recovery, simple synthesis process, easy to popularize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

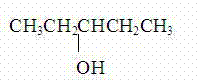

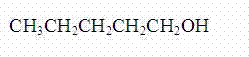

[0033] A collophosite reverse flotation collector, (1) 20 grams of stearic acid with a content greater than 90% as the main raw material; (2) 2.2 grams of mixed alcohol as the secondary raw material, mixed with the main raw material, of which the main The raw materials account for 90% of the total mass of the mixture, and the secondary raw materials account for 10% of the total mass of the mixture.

[0034] A preparation method of collophosite reverse flotation collector, which is characterized in that: the mixture is mixed with 10 grams of 30% liquid caustic soda and then reacted in a constant temperature reactor at 110°C for 1 hour to obtain 30°C) reverse flotation collector with good downflow mobility and dispersibility, good collection performance and selectivity.

[0035] When raw ore P 2 o 5 content of 21%, MgO content of 5%, add 400 g / ton of raw ore collector for reverse flotation operation, when the MgO content in the concentrate is 0.7%, and the MgO removal rate r...

Embodiment 2

[0047] A collophosite reverse flotation collector is characterized in that it is mainly due to: (1) 20 grams of stearic acid with a content greater than 90% as the main raw material; (2) 5 grams of mixed alcohol as the secondary raw material, Mix with the main raw materials, where the main raw materials account for 80% of the total mass of the mixture, and the secondary raw materials account for 20% of the total mass of the mixture.

[0048] A preparation method of collophosite reverse flotation collector, which is characterized in that: the mixture is mixed with 10 grams of 30% liquid caustic soda and then reacted in a constant temperature reactor at 110°C for 1 hour to obtain 30°C) reverse flotation collector with good downflow mobility and dispersibility, good collection performance and selectivity.

[0049] When raw ore P 2 o 5 content of 21%, MgO content of 5%, add 400 g / ton of raw ore collector for reverse flotation operation, when the MgO content in the concentrate ...

Embodiment 3

[0051] A collophosite reverse flotation collector is characterized in that it is mainly due to: (1) 20 grams of stearic acid with a content greater than 90% as the main raw material; (2) 8.6 grams of mixed alcohol as the secondary raw material, Mix with the main raw materials, where the main raw materials account for 70% of the total mass of the mixture, and the secondary raw materials account for 30% of the total mass of the mixture.

[0052] A preparation method of collophosite reverse flotation collector, which is characterized in that: the mixture is mixed with 10 grams of 30% liquid caustic soda and then reacted in a constant temperature reactor at 110°C for 1 hour to obtain 30°C) reverse flotation collector with good downflow mobility and dispersibility, good collection performance and selectivity.

[0053] When raw ore P 2 o 5 content of 21%, MgO content of 5%, add 400 g / ton of raw ore collector for reverse flotation operation, when the MgO content in the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com