Combined universal rolling production line and production method of profile steels

A universal rolling and production line technology, applied in metal rolling and other directions, can solve the problems of a large number of rolling mills, a large plant area, and many rolling passes, so as to reduce the workshop area, save investment, reduce rolling line The effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

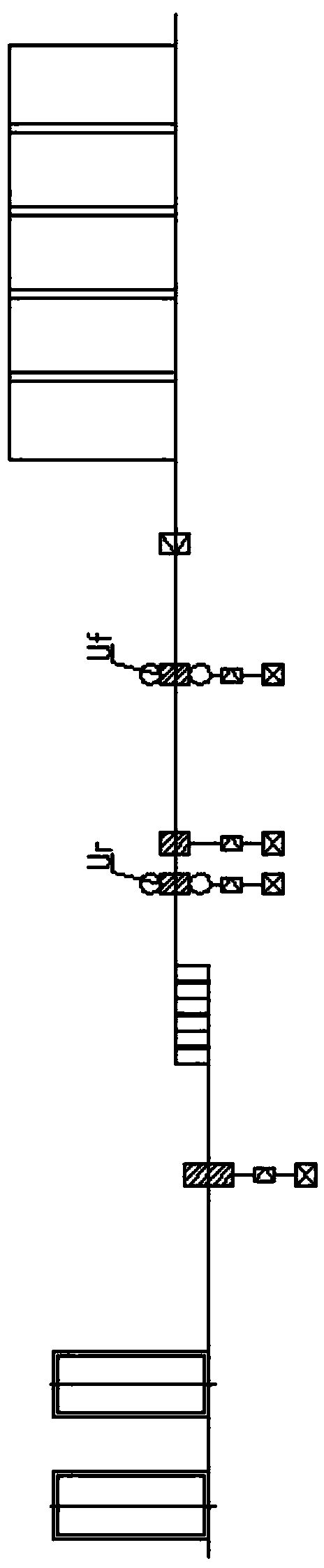

[0048] Figure 6 It is a schematic diagram of the process plane layout of the present invention. As shown in the figure, the combined section steel universal rolling production line of the present invention includes a heating furnace 1, a blanking machine rolling unit 2, an archway universal rolling mill rolling unit 3, Short stress line type universal rolling mill rolling unit 4 and cooling bed 5; the billet rolling mill rolling unit 2 includes at least one two-roll or four-roll universal rolling mill, and the rolling mill of the brand house type universal rolling mill rolling unit 3 The number is 3 stands, and the number of rolling mills in the rolling unit 4 of the short stress line universal rolling mill is 4 to 12 stands. The billet coming out of the heating furnace 1 is rolled through the rolling unit 2 of the blanking machine, the rolling unit 3 of the archway universal rolling mill and the rolling unit 4 of the short stress line universal rolling mill to obtain finishe...

Embodiment 2

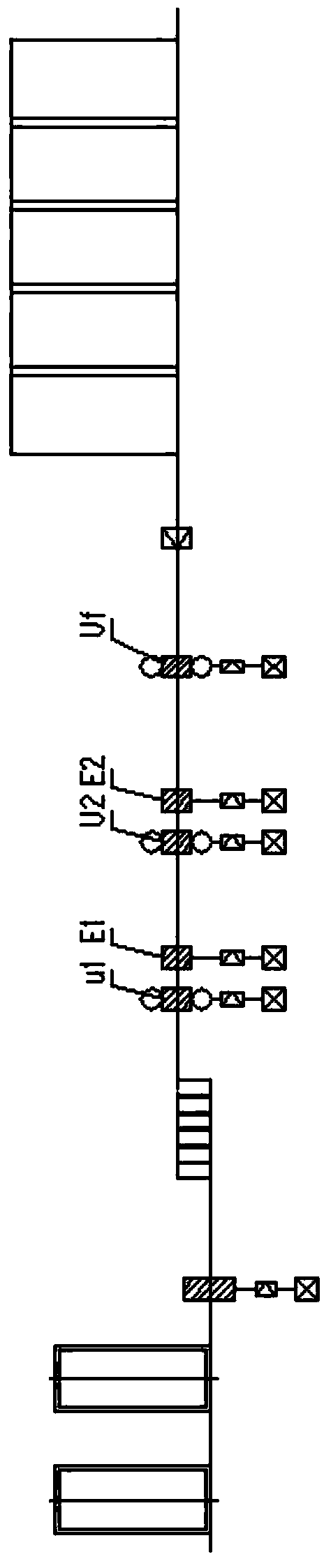

[0054] Figure 8 It is a schematic diagram of the pass system and the production process of Example 2 of the present invention. As shown in the figure, as an improved rolling method for producing section steel in the combined section steel universal rolling production line in Example 1, the billet coming out of the heating furnace 1 enters the opening The rolling unit 2 of the billet machine carries out reciprocating rolling of odd passes; the rolled piece is turned over and adjusted by the steel turning device 6 and centered, and the rolled piece adopts a vertical posture and enters the subsequent rolling unit for rolling, and then passes through the archway type universal The rolling unit 3 of the rolling mill performs reciprocating rolling for 6 to 18 passes, the elongation coefficient of each pass of the rolling unit 3 of the archway type universal rolling mill is 1.0 to 1.4 during the rolling process, and the short stress line universal rolling mill The rolling unit 4 doe...

Embodiment 3

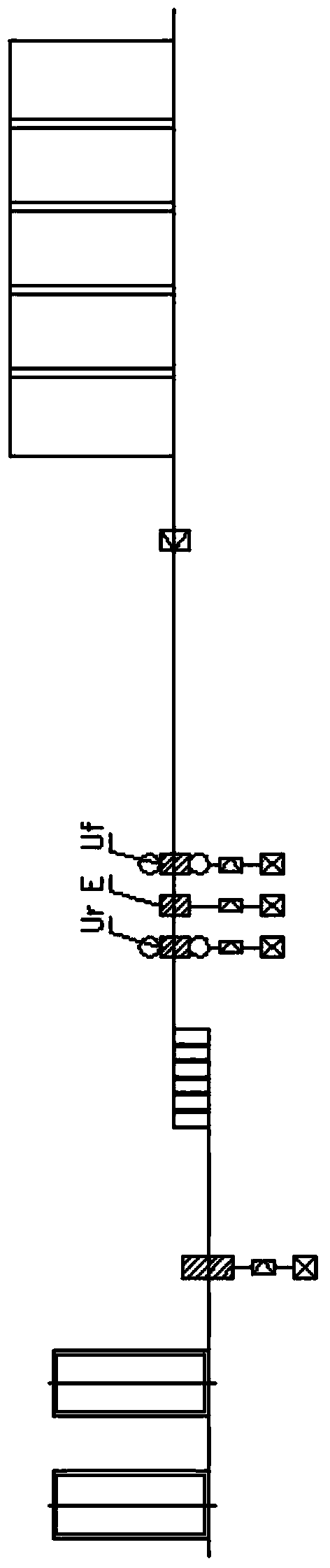

[0056] Figure 9 It is a schematic diagram of the pass system and production process of Embodiment 3 of the present invention. As shown in the figure, the method for producing profiled steel using the above-mentioned combined profiled steel universal rolling production line, the billet coming out of the heating furnace 1 enters the rolling unit 2 of the blanking machine Carry out reciprocating rolling of odd passes; the rolled piece adopts the traditional horizontal posture to enter the follow-up rolling unit for rolling, and then conducts continuous rolling for one pass through the short stress line type universal rolling mill rolling unit 4, the short stress line type The rolling unit 4 of the universal rolling mill has an elongation coefficient of 1.0 to 1.4 for each pass during the rolling process, and the rolling unit 3 of the archway-type universal rolling mill does not participate in rolling, and the rolling station moved out is filled by an empty roller table; The prod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap