Material separating mechanism applied to welding line

A welding line and fixing bracket technology, applied in auxiliary devices, welding equipment, transportation and packaging, etc., can solve the problems of high maintenance cost, high cost, and inability to meet production management, so as to reduce maintenance costs, reduce equipment costs, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

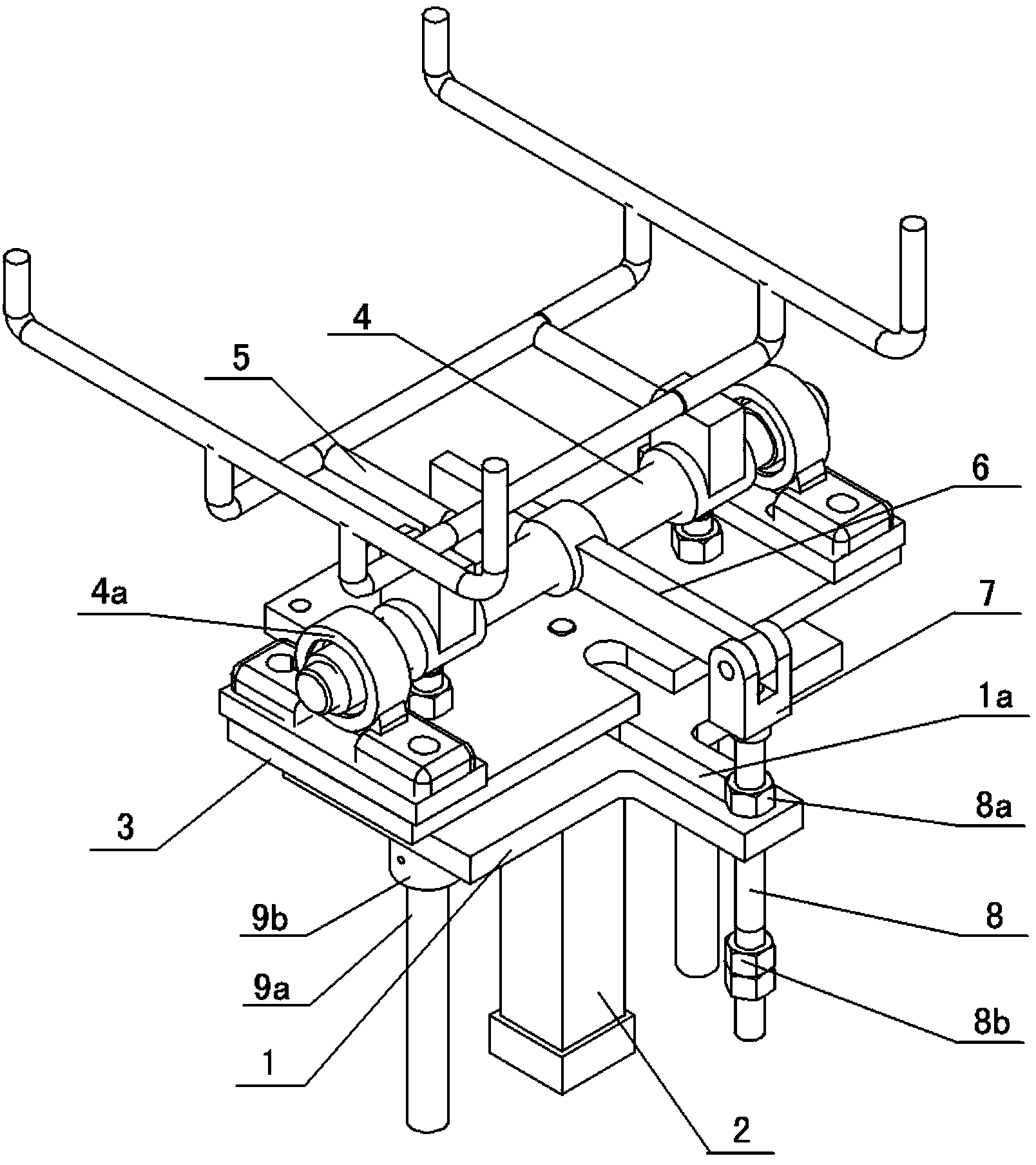

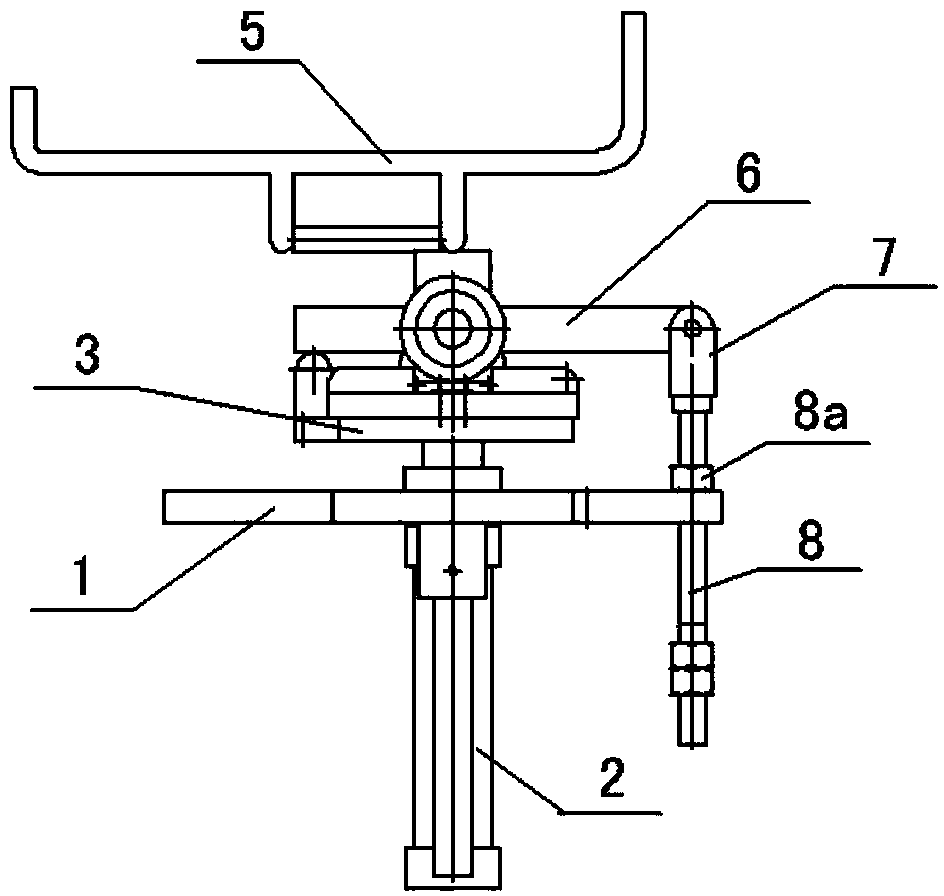

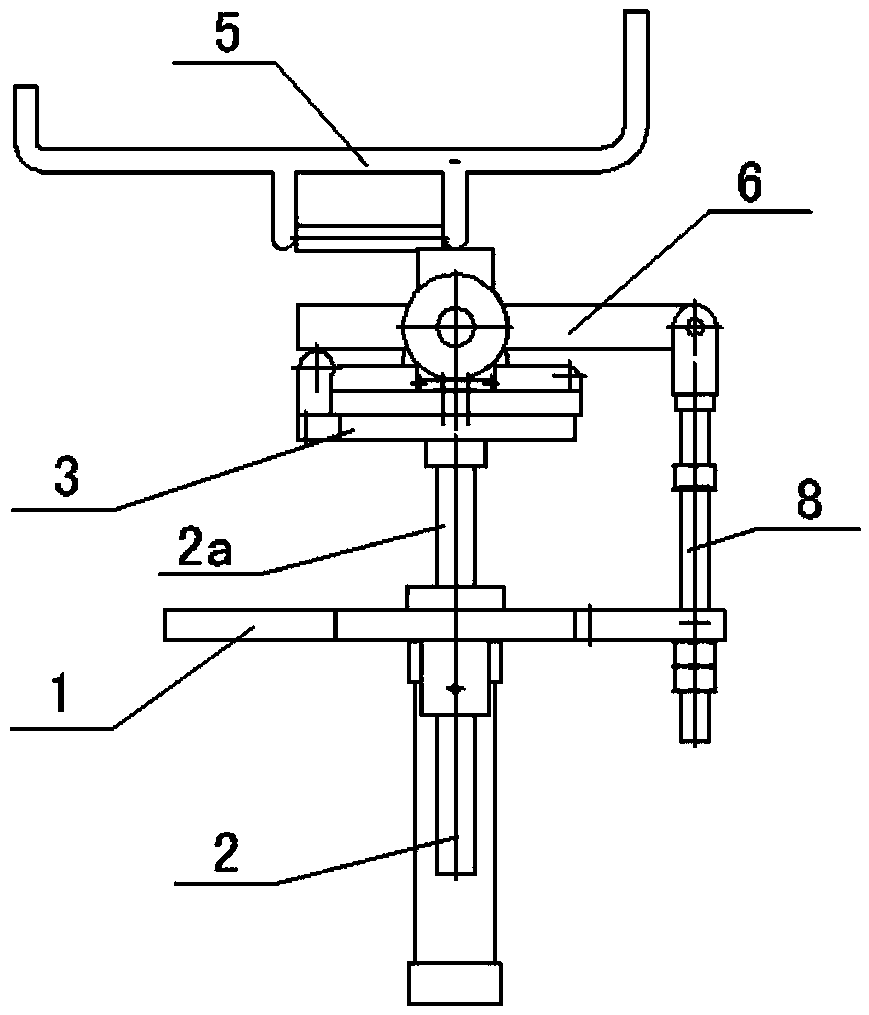

[0019] see figure 1 , figure 2 , the structural form of the stripping mechanism applied on the welding line in this embodiment is:

[0020] A fixed bracket 1 is arranged horizontally, and the jacking cylinder 2 is fixedly arranged on the fixed bracket 1. The piston rod 2a of the jacking cylinder 2 is vertically upward above the fixed bracket as a jacking rod, and the jacking platform 3 is fixedly arranged on the piston rod. The top of 2a is provided with a transverse guide slot 1a on one side of the fixed bracket 1;

[0021] A longitudinal horizontal strut 4 is fixedly arranged on the jacking platform 3, and the bracket frame 5 is horizontally fixedly connected to the longitudinal horizontal strut 4; One end of the rod 6 extends to the outside of the jacking platform, and is hinged with the connecting block 7, and the connecting block 7 is fixedly connected to the top of the vertical guide rod 8;

[0022] The vertical guide rod 8 runs through the horizontal guide long hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap