Oval Hole Cutting Technology of Wind Power Foundation Ring

A technology of wind power generation foundation and cutting technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as foundation ring deformation, achieve simple cutting, strong integrity, and ensure construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

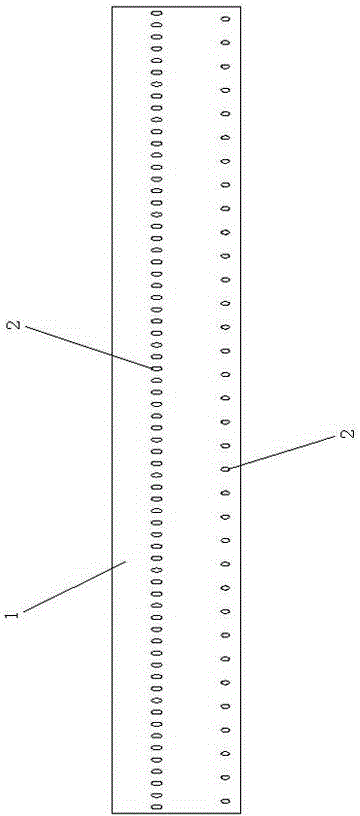

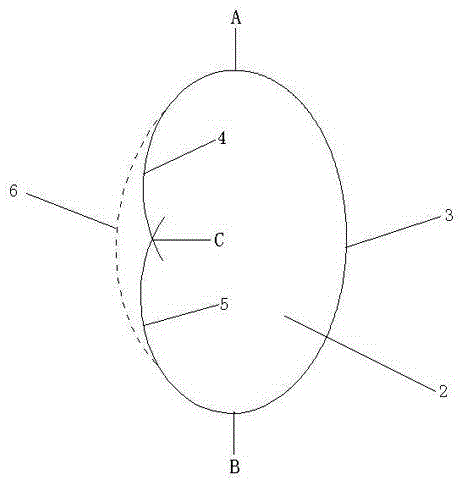

[0014] Example 1, such as figure 1 As shown, a wind power generation base ring elliptical hole cutting process is characterized in that: the basic ring 1 is an annular steel cylinder, and the elliptical hole 2 is arranged on the annular steel cylinder. The process includes the following steps:

[0015] Step 1), selection of steel: according to the weight of the fan tower, the weight of the base ring 1, the diameter of the base ring 1, the thickness of the tube wall, the number of elliptical holes 2, and the size of the elliptical hole 2, select steel types of different strength levels, to meet the strength requirements;

[0016] Step 2), cutting machine data programming: according to the number and size of the oval hole 2, data programming is performed on the CNC plasma cutting machine;

[0017] Step 3) Cutting rehearsal: According to the programmed data, perform cutting rehearsal on the base ring 1. The cutting rehearsal includes large ellipse arc cutting rehearsal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com