Shearing unit automatic production line structure

An automated production line and unit technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

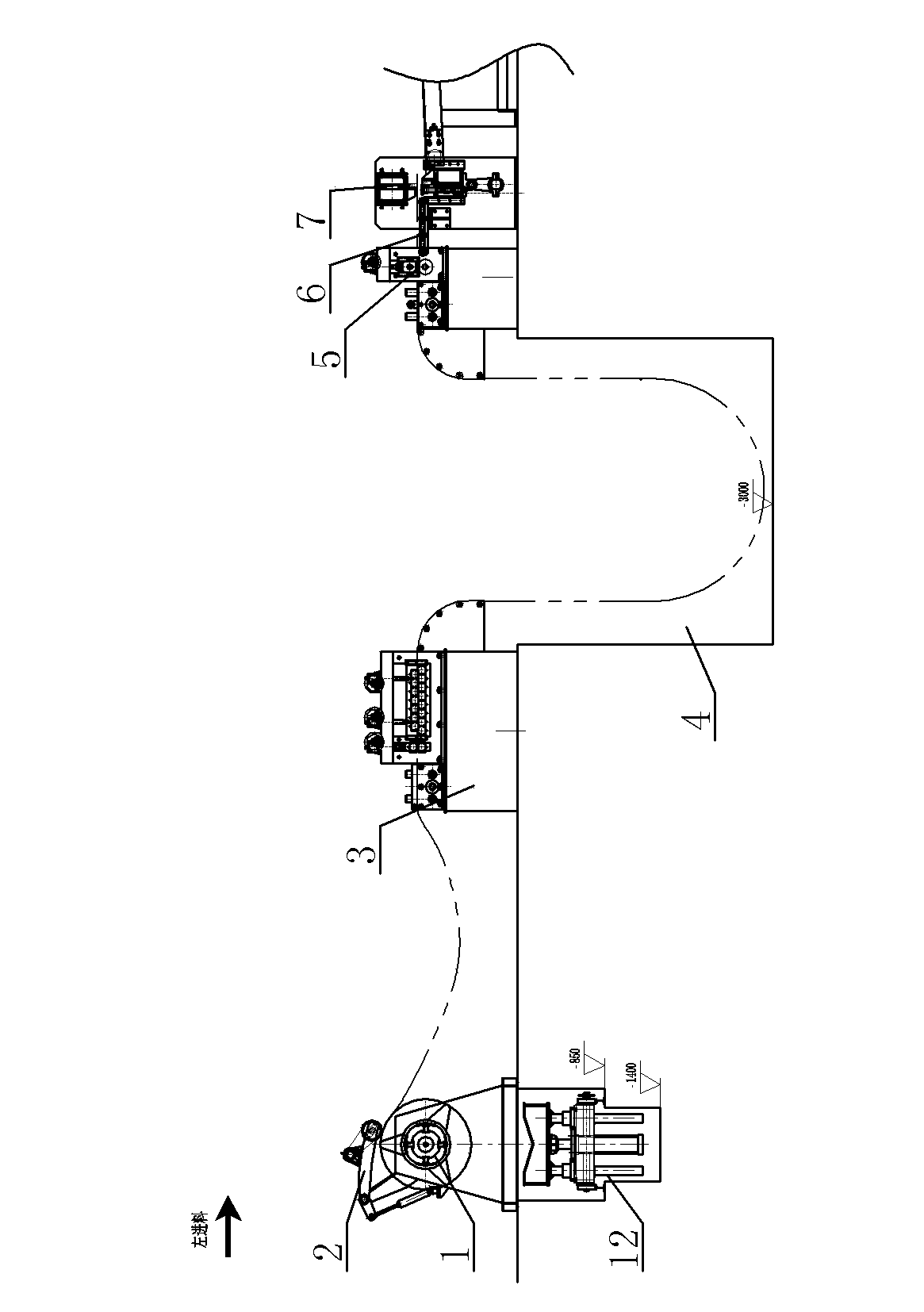

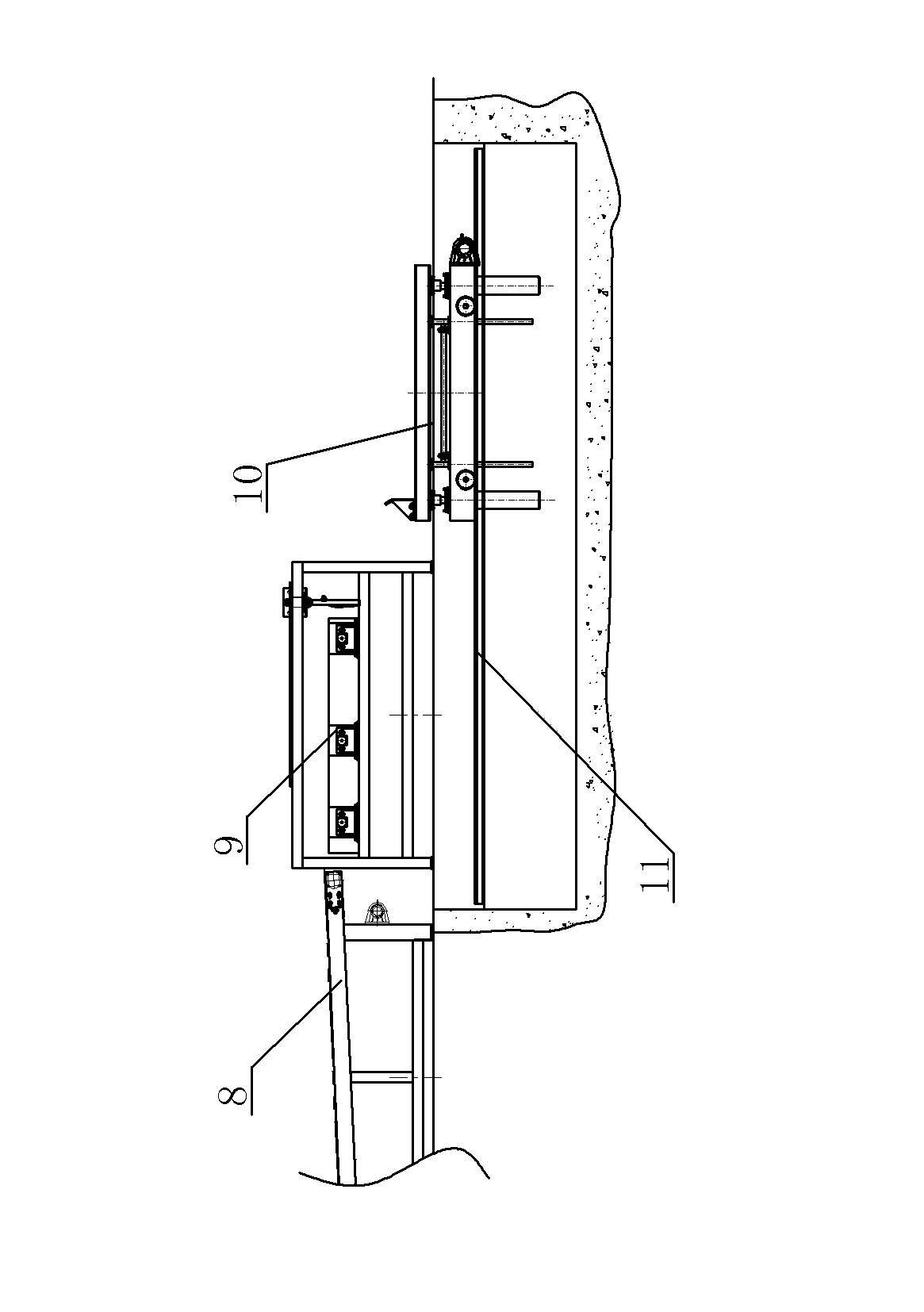

[0010] An automatic production line structure of a leveling unit: see Figure 1 ~ Figure 2 , Which includes an uncoiler 1, a lead structure 2 is arranged above the uncoiler 1, a leveler 3 is arranged behind the uncoiler 1, and a looper storage cavity 4 is arranged behind the leveler 3. A sizing machine 5 is arranged behind the output end. The output end of the sizing machine 5 is connected to the cross-cutting machine 7 through a guide roller 6. The output end of the cross-cutting machine 7 leads to the inlet side of the belt conveyor 8 and the outlet of the belt conveyor 8 The side leads to the collecting rack 9, and the lower exit of the collecting rack 9 is provided with a transport trolley 10, the transport trolley 10 is located on the guide rail 11, and the guide rail 11 leads to the station to be loaded. The leveling machine 3 is specifically a seventeen-roll leveling machine with two pinch rolls and fifteen leveling rolls, and a feeding trolley 12 is arranged under the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com