Processing technology for tempered glass protection screen

A technology of tempered glass and processing technology, applied in glass/slag layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of inability to meet the needs of consumers, short service life, low light transmittance, etc. , to achieve the effect of good impact resistance, super scratch resistance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

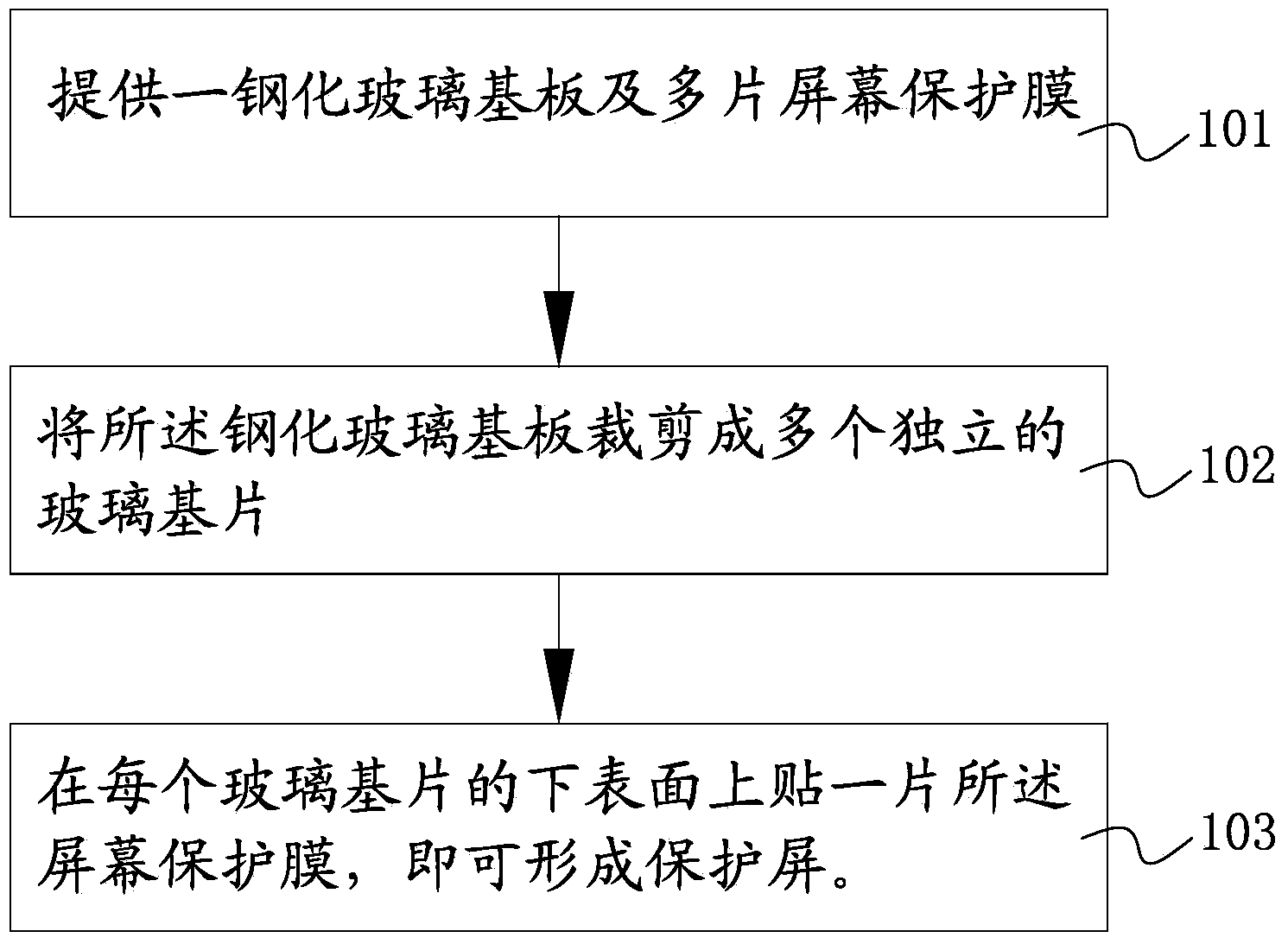

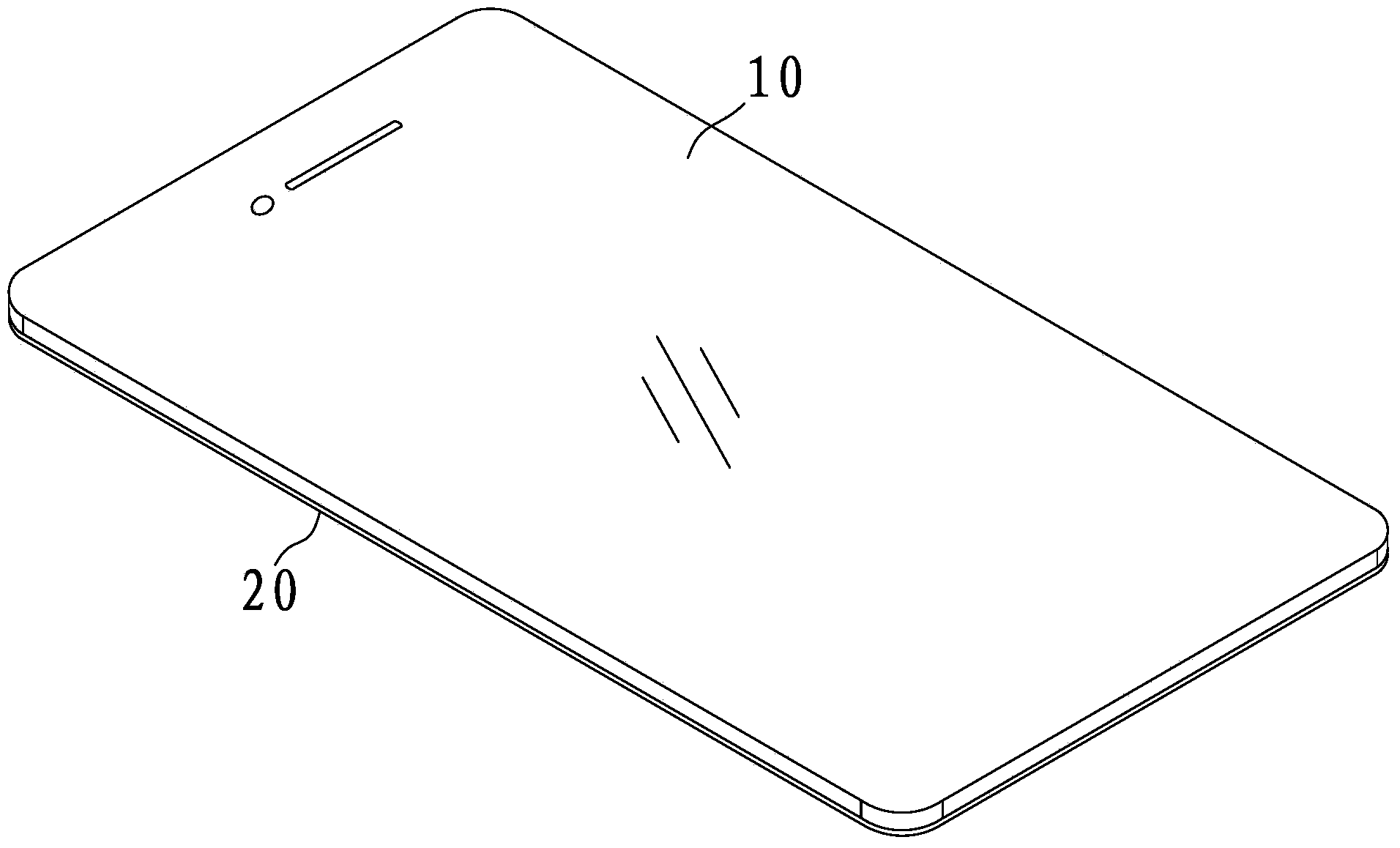

[0044] refer to Figure 1 to Figure 3 As shown, the present embodiment provides a kind of processing technology of tempered glass protective screen, and it comprises the following steps:

[0045] Step 101: Provide a tempered glass substrate and multiple pieces of screen protection film 20, the thickness of the tempered glass substrate is 0.1-1.0MM, the screen protection film 20 includes a substrate, the substrate has an upper surface and a lower surface, the The upper surface of the substrate is covered with an optical adhesive layer for bonding with the tempered glass substrate, and the lower surface of the substrate is covered with a silica gel layer, which is used for contact with display terminals such as mobile phones and tablet computers during the use of the protective screen. The display snaps together.

[0046] Step 102: Cut the tempered glass substrate into a plurality of independent glass substrates 10, the shape and size of each glass substrate 10 are adapted to t...

Embodiment 2

[0060] refer to Figure 4 to Figure 6 As shown, the processing technology of the tempered glass protective screen provided in this embodiment includes steps:

[0061] Step 101: Provide a tempered glass substrate and multiple pieces of screen protection film 20, the thickness of the tempered glass substrate is 0.1-1.0MM, the screen protection film 20 includes a base material, the base material has an upper surface and a lower surface, the The upper surface of the substrate is covered with an optical adhesive layer, and the lower surface of the substrate is covered with a silica gel layer. This step is the same as in Embodiment 1.

[0062] Step 102: cutting the tempered glass substrate into a plurality of independent glass substrates 10, the shape and size of each glass substrate 10 are adapted to the shape and size of the display screen of the display terminal. In addition, if there is a speaker hole or the like at the corresponding position of the display screen of the displ...

Embodiment 3

[0068] refer to Figure 7 to Figure 9 As shown, the processing technology of the tempered glass protective screen provided in this embodiment includes steps:

[0069] Step 101: Provide a tempered glass substrate and multiple pieces of screen protection film 20, the thickness of the tempered glass substrate is 0.1-1.0MM, the screen protection film 20 includes a base material, the base material has an upper surface and a lower surface, the The upper surface of the substrate is covered with an optical adhesive layer, and the lower surface of the substrate is covered with a silica gel layer. This step is the same as in Embodiment 1.

[0070] Step 102: cutting the tempered glass substrate into a plurality of independent glass substrates 10, the shape and size of each glass substrate 10 are adapted to the shape and size of the display screen of the display terminal. In addition, if there is a speaker hole or the like at the corresponding position of the display screen of the displ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com