Semi-rigid solar battery wing of spacecraft

A technology for space vehicles and solar cells, which is applied to the power supply system of aerospace vehicles, etc., can solve the problems of circuit short-circuit failure mode, low power generation efficiency, unsuitable space use, etc., to achieve good atomic oxygen resistance, high bearing capacity, and power generation. high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] At present, the solar cell wings used in the space orbit environment in our country are all rigid solar cell wings. Due to the complex space environment of aircraft flight, the traditional rigid solar cell wings are gradually unsuitable as solar cell wings for space vehicles.

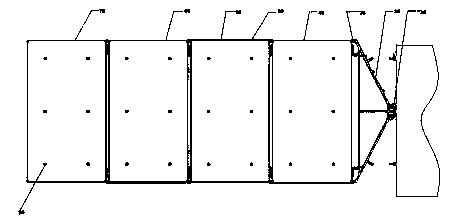

[0025] In view of the foregoing, the technical solution of the present invention provides a semi-rigid solar battery wing of a space vehicle, such as figure 1 The semi-rigid solar cell wing shown comprises:

[0026] A root deployment locking mechanism 19 connected to the spacecraft;

[0027] Inter-panel deployment locking mechanism 20;

[0028] A connecting frame 30 connecting the root deployment locking mechanism 19 and the inter-board deployment locking mechanism 20;

[0029] The inner semi-rigid battery board 40 , the middle inner semi-rigid battery board 50 , the middle and outer semi-rigid battery board 60 and the outer semi-rigid battery board 70 which are connected in sequence;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com