High-precision, miniaturized, high-torque output deploying device

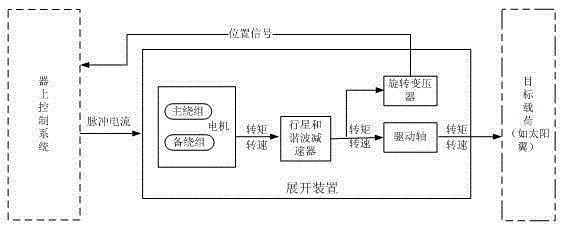

A high-precision, high-torque technology, which is applied in the power supply system of aerospace vehicles and other directions, can solve the problems of inability to meet the large-area solar wing deployment and large-torque requirements, inability to adapt to the high vacuum of the moon surface, large temperature difference, and high weight requirements of the drive mechanism , to achieve the effect of light weight, large output torque and stable deployment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

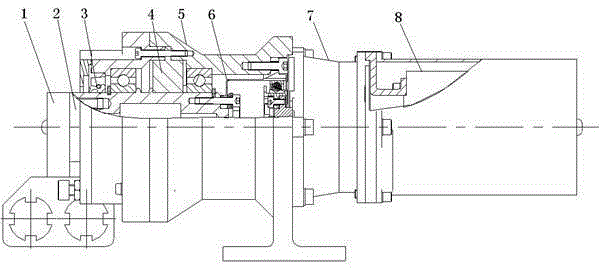

[0020] The present invention provides a high-precision, miniaturized, high-torque output expansion device, which includes a stepping motor 8, a planetary gear reducer 7, a harmonic reducer 6, a resolver 4, an output shaft 2, a male hinge 1, and a housing 5;

[0021] Stepper motor 8 is used to provide driving power, planetary gear reducer 7 and stepper motor 8 are integrated structure, planetary gear reducer 7 is connected with harmonic reducer 6, planetary gear reducer 7 and harmonic reducer 6 are used Reduce the speed provided by the stepper motor 8;

[0022] The output shaft 2 and the harmonic reducer 6 are an integrated structure, the output shaft 2 is connected with the male hinge 1, and the male hinge 1 is used to connect the target load;

[0023] The rotor of the resolver 4 is connected to the output shaft 2, the stator of the resolver 4 is connected to the housing 5, and the resolver 4 is used for high-precision control of the output shaft 2.

[0024] The high-precision, minia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com