A coal storage silo feeding device

A technology of feeding device and screw feeding device, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of uncontrollable high temperature zone in the center of silo, inert gas failure, and no disclosure of feeding device, etc. The effect of high sealing degree, good sealing performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

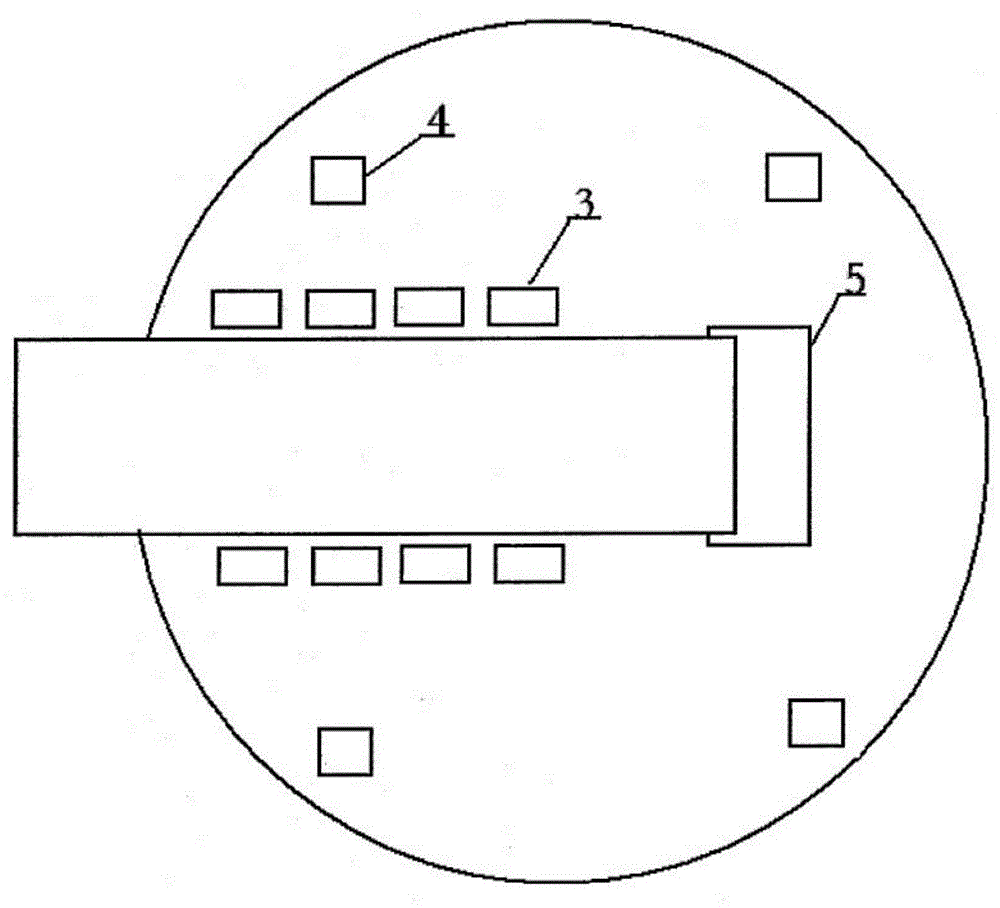

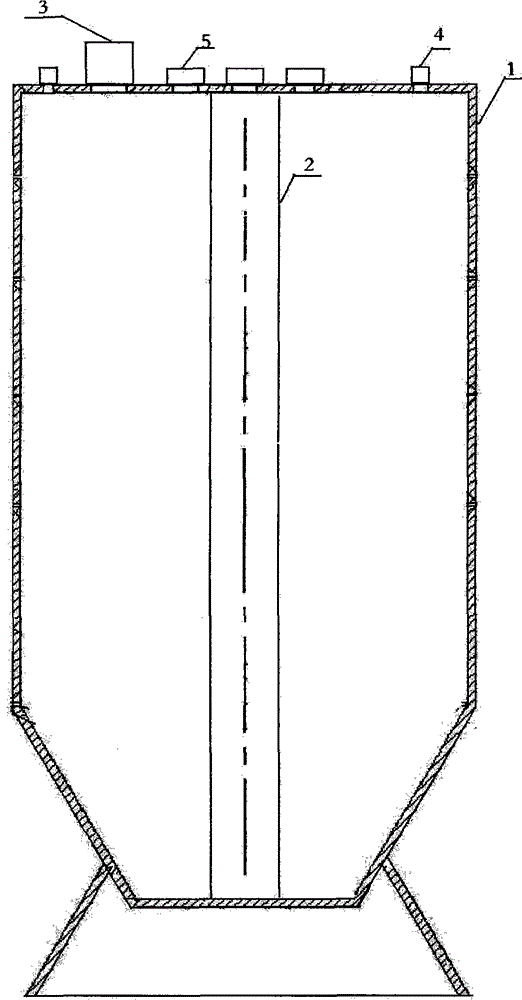

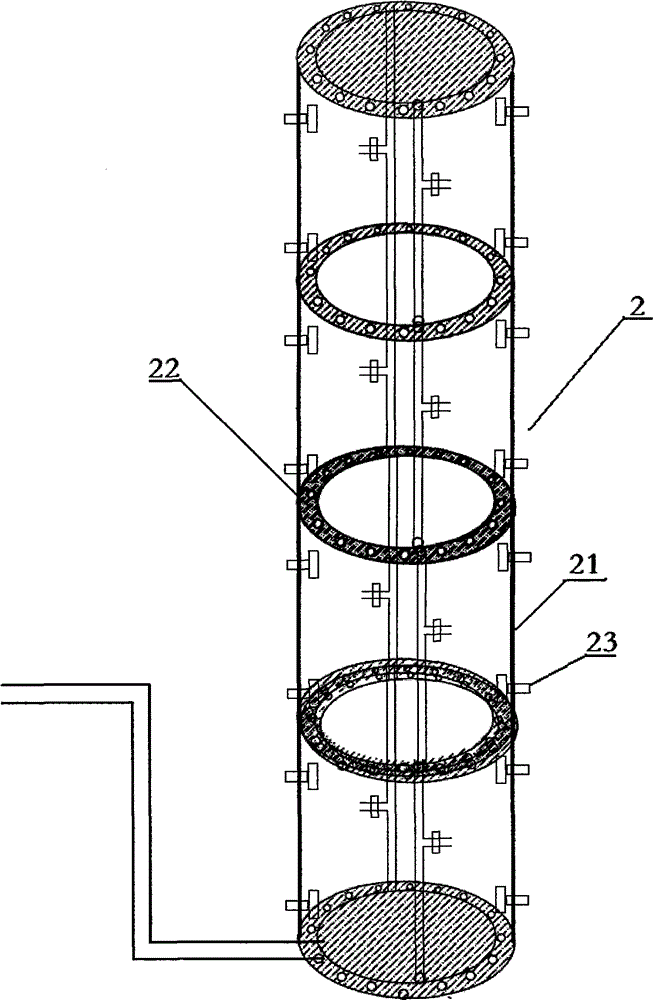

[0024] Figure 1 is a schematic diagram of a safety protection device for a central inerting tubular coal storage silo. Central inerting tubular coal storage silo 1 has a diameter of 10-20 meters and a height of 40 meters. An automatic air-locking funnel device 3, an automatic pressure relief device 4 and a sealing screw feeding device 5 are installed on the top of the silo, and a tubular aeration device 2 is installed at the center of the silo. Above the top of the silo, there is a belt conveyor BELT for transporting materials. The automatic air-locking funnel device is installed on both sides of the belt conveyor, and there are 3-4 on each side of each warehouse, which are used to receive the materials sent by the belt conveyor. The silo mainly relies on the automatic air-locking funnel for feeding. The sealed screw feeding device is set at the tail end of the belt transmission device, that is, under the belt roller, to receive the remaining materials on the belt. The autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com