Technology for treating and recycling fracturing flow-back fluid of oil and gas field

A technology for fracturing flowback fluid and oil and gas fields, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of reducing the amount of sewage, avoiding secondary pollution, and reducing degradation products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fracturing fluid flowback fluid waste in the Hailaer block of Daqing Oilfield is transported to the fracturing flowback fluid treatment station by tank truck. The specific process is as follows:

[0025] Step S1: Recover the waste fluid of the fracturing flowback fluid through oil separation to obtain recovered waste fluid.

[0026] The waste liquid of fracturing flowback fluid is unloaded in the waste oil recovery tank, and the waste oil continuously settles and separates to float on the liquid surface. After being recovered by the oil skimmer, the recovered waste liquid is obtained, and transported by the liquid tanker to the combined station for treatment. The oil separation recovery time is 55min.

[0027] Step S2: Degrading the recovered waste liquid to obtain degraded waste liquid.

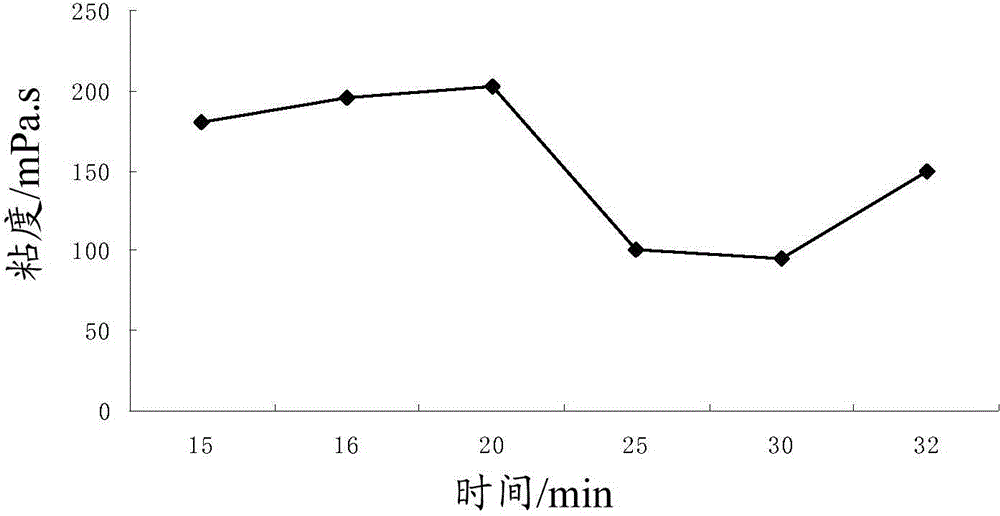

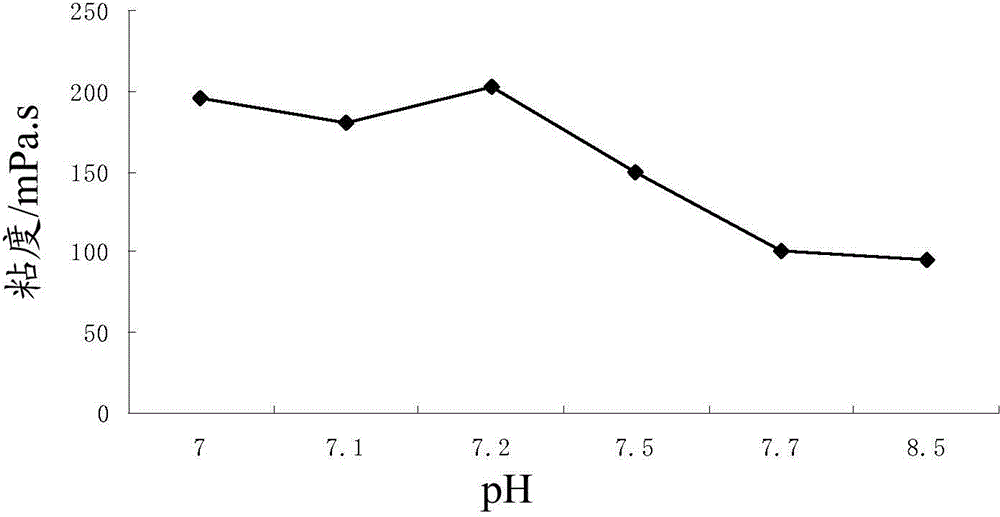

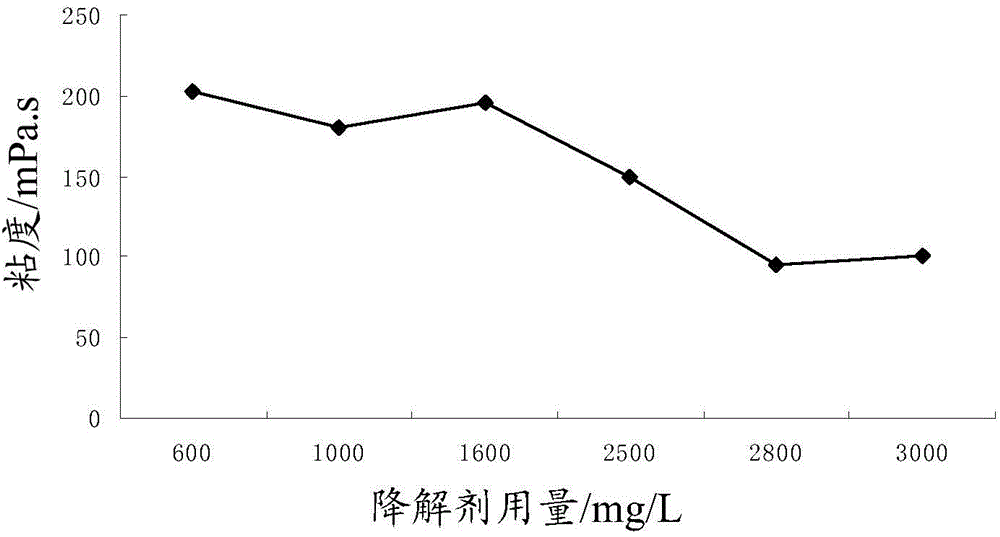

[0028] The recovered waste liquid enters the oxidation tank through the pipeline from the waste oil recovery tank, and bacteria species are added and a large amount of oxygen is...

Embodiment 2

[0038] The waste fracturing flowback fluid in the Outer Mengtamchag block of Daqing Oilfield is transported to the fracturing flowback fluid treatment station by tank truck. The specific process is as follows:

[0039] Step S1: Recover the waste fluid of the fracturing flowback fluid through oil separation to obtain recovered waste fluid.

[0040] The waste liquid of fracturing flowback fluid is unloaded in the waste oil recovery tank, and the waste oil continuously settles and separates to float on the liquid surface. After being recovered by the oil skimmer, the recovered waste liquid is obtained, and transported by the liquid tanker to the combined station for treatment. The oil separation recovery time is 60min.

[0041] Step S2: Degrading the recovered waste liquid to obtain degraded waste liquid.

[0042] The recovered waste liquid enters the oxidation tank through the pipeline from the waste oil recovery tank, and bacteria species are added and a large amount of oxyge...

Embodiment 3

[0052] The waste fracturing flowback fluid in the Zhaoyuan block of Daqing Oilfield is transported to the fracturing flowback fluid treatment station by tanker truck. The specific process is as follows:

[0053] Step S1: Recover the waste fluid of the fracturing flowback fluid through oil separation to obtain recovered waste fluid.

[0054] The waste liquid of fracturing flowback fluid is unloaded in the waste oil recovery tank, and the waste oil continuously settles and separates to float on the liquid surface. After being recovered by the oil skimmer, the recovered waste liquid is obtained, and transported by the liquid tanker to the combined station for processing. The oil separation recovery time is 50min.

[0055] Step S2: Degrading the recovered waste liquid to obtain degraded waste liquid.

[0056] The recovered waste liquid enters the oxidation tank through the pipeline from the waste oil recovery tank, and bacteria species are added and a large amount of oxygen is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com