High-efficiency flocculation device and sludge dewatering treatment system

A flocculation device, high-efficiency technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of reduced equipment use efficiency, reduced space utilization rate, reduced equipment capacity, etc. problems, to achieve the effect of high equipment use efficiency, high space utilization rate, and reduced pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

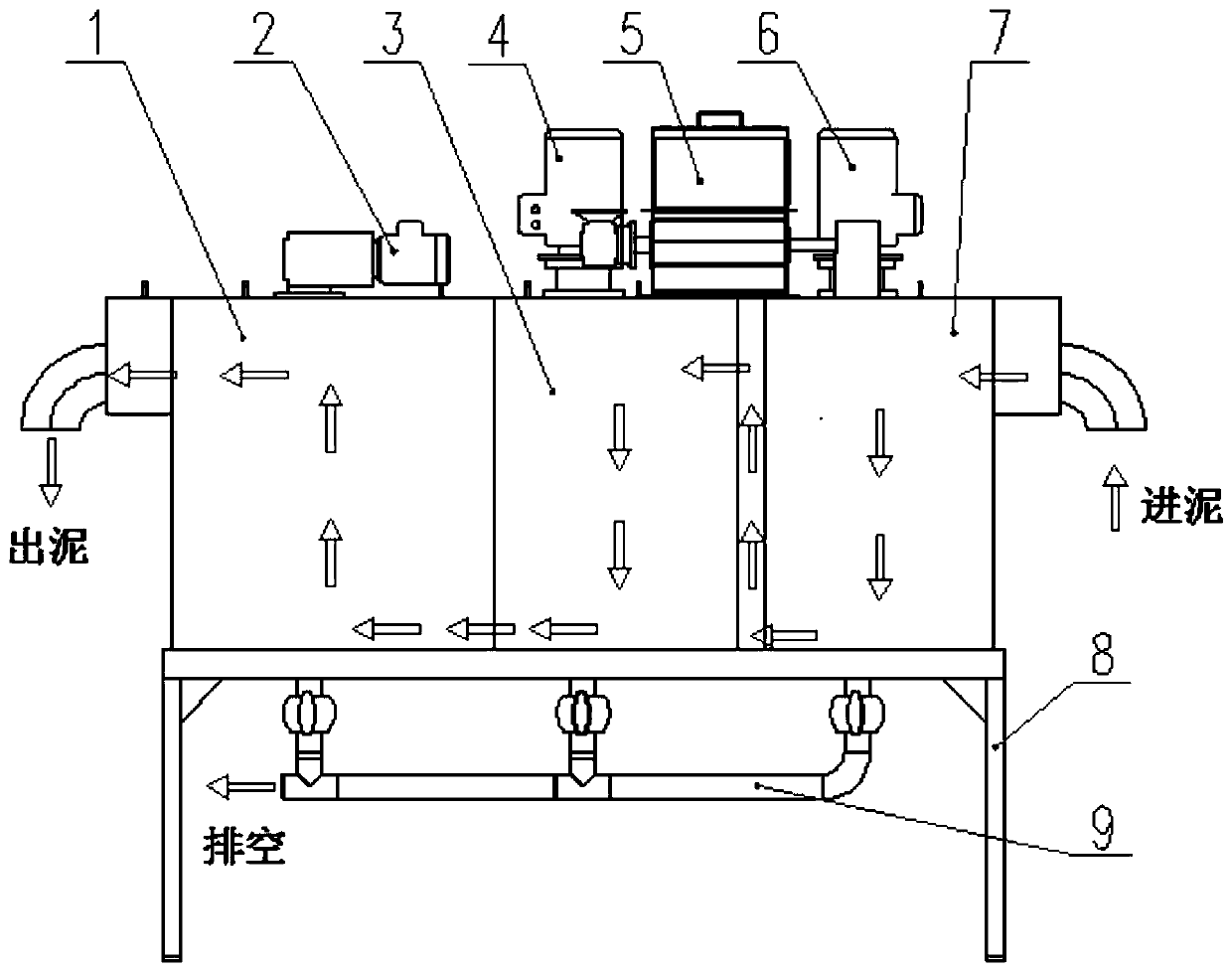

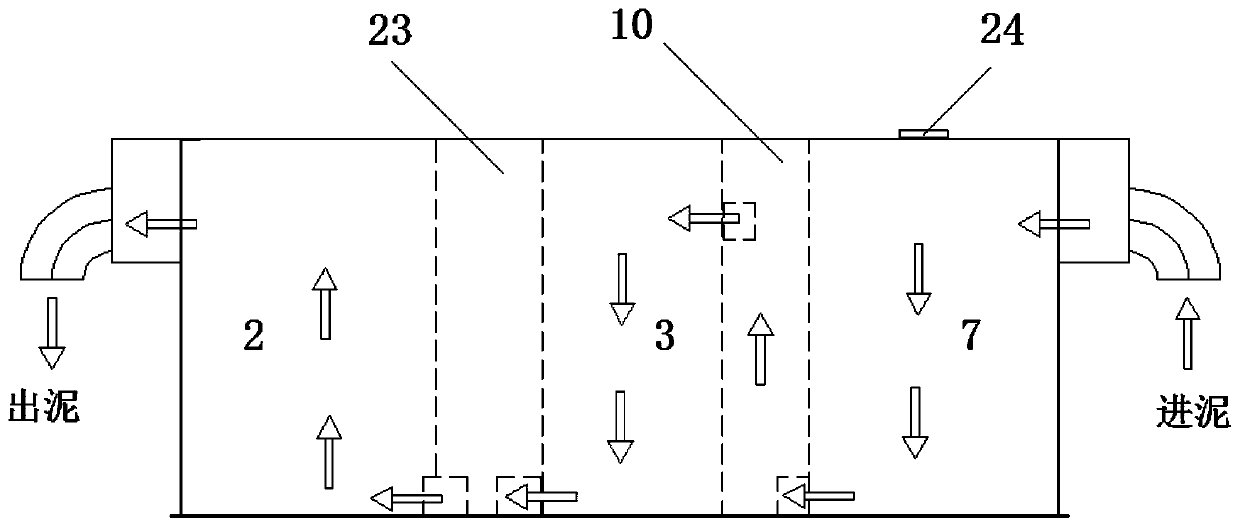

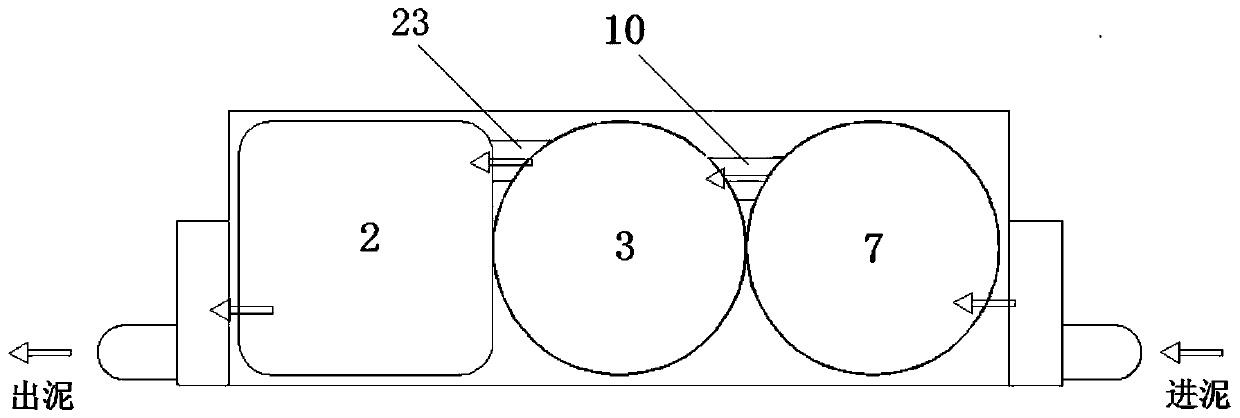

[0046] Such as figure 1 , figure 2 , image 3 As shown, a high-efficiency flocculation device of the present invention is mainly composed of the following three parts: a high-efficiency flocculation mixing main body, a dry powder dosing system 5 and a bottom support mechanism 8; A box structure composed of multiple boxes including the flocculation mixing tank; the upper part of one side of the box structure is a mud inlet, and the upper part of the other side is a mud outlet; the multiple boxes include three boxes , that is, the preliminary mud mixing box 7, the aging mud mixing box 3, and the flocculation mixing tank 1 connected in sequence; the mud mixing device 6 is arranged in the preliminary mud mixing box 7; Medicine mixing device 4; flocculation mixing tank 1 is equipped with flocculation mixing device 2; mud mixing box (including preliminary mud mixing box 7, matured mud mixing box 3) has a mud inlet at the top and a mud outlet at the bottom , the flow direction o...

Embodiment 2

[0061] The present invention adopts the sludge dewatering treatment system of the above-mentioned high-efficiency flocculation device, such as Figure 8 As shown, it includes a feed system and a dewatering system that are connected in sequence; the feed system includes a sludge tank and a feed pump; the dewatering system includes the high-efficiency flocculation device described in Example 1, the stacked screw sludge dewatering machine (screw stacker) ); the inlet of the feed pump is connected to the sludge tank; the outlet of the feed pump is connected to the mud inlet of the high-efficiency flocculation device; the sludge outlet of the high-efficiency flocculation device is connected to the mud inlet of the screw stacker.

[0062] Its working process is as follows: the sludge from the sewage plant is pumped into the above-mentioned high-efficiency flocculation device from the sludge tank through the feed pump. After the sludge and chemicals complete the flocculation mixing re...

Embodiment 3

[0067] Such as figure 1As shown, a high-efficiency flocculation device of the present invention includes a high-efficiency flocculation mixing main body, a dry powder dosing system 5 and a bottom support mechanism 8; A box structure composed of a plurality of boxes; the upper part of one side of the box structure is a mud inlet, and the upper part of the other side is a mud outlet; the plurality of boxes includes three boxes, that is, the preliminary mud Medicine mixing box 7, aging mud mixing box 3, flocculation mixing tank 1; preliminary mud mixing box 7 is provided with mud mixing device 6; ripening mud mixing box 3 is provided with mud mixing device 4; flocculation The mixing tank 1 is provided with a flocculation mixing and stirring device 2; the upper part of the mud mixing box (including the preliminary mud mixing box 7 and the mature mud mixing box 3) is provided with a mud inlet, and the lower part is provided with a mud outlet. The flow direction of the fluid (that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com