Air outlet head of a glass blowing machine

A technology of air outlet and bubble blowing machine, applied in the direction of blowing head, etc., can solve the problems of high nozzle pressure, glass cannot reach the shape, glass bubble rupture, etc., to ensure the effect of exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

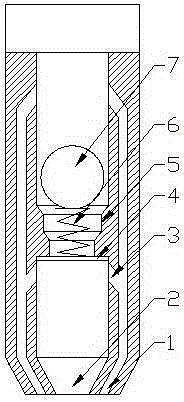

[0014] Do further description below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, an air outlet head of a glass blowing machine, the air outlet head includes a cylindrical main body, a main air outlet channel 2, an auxiliary air outlet channel 1, and a throttle valve, and the main air outlet channel 2 is arranged on the cylindrical main body The central part runs through the entire cylindrical main body longitudinally, one end of the cylindrical main body is an air inlet and the other end is an air outlet; the auxiliary air outlet channel 1 is arranged between the outer wall of the main air outlet channel 2 and the outer wall of the cylindrical main body, and The auxiliary air outlet channel 1 is composed of several branch auxiliary air outlet channels 1, and the inlet end of the auxiliary air outlet channel 1 of the branch road is arranged on the inner wall of the main air outlet channel 2 near the air inlet, and is connected with the main air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com