Air exhausting device of centrifugal pump

A technology of exhaust device and centrifugal pump, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the problems of oil mixing into the air and reduce the transmission speed, so as to improve the user experience and avoid the leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

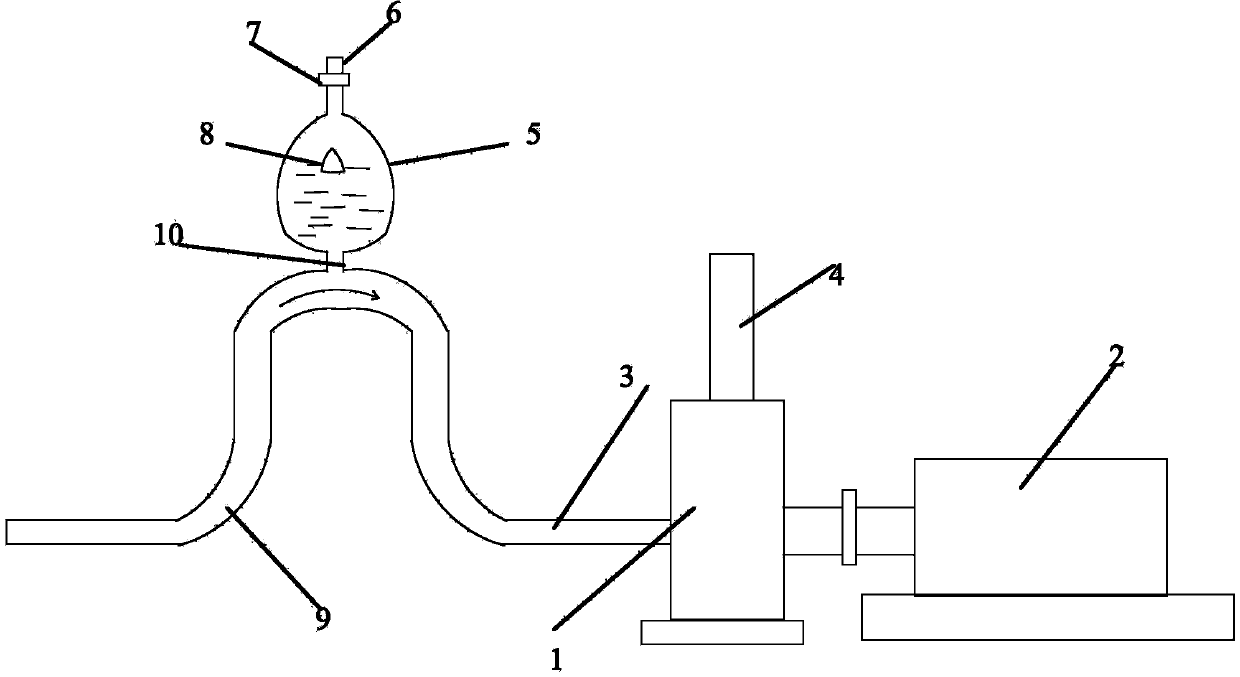

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0013] Such as figure 1 As shown, an exhaust device of a centrifugal pump of the present invention, that is, the centrifugal pump 1 is driven to rotate by a motor 2 through a coupling, and the feed port and the discharge port pass through the feed pipe 3 and the discharge pipe 4 respectively. It communicates with the corresponding feed tank, and the feed tank is an emu oil tank to be moved or processed, and an exhaust tank 5 is fixedly arranged in communication with it on the feed pipe at the front of the feed inlet, The exhaust tank is preferably made of steel, which is vertically fixed by a bracket or a hoop structure, while an exhaust pipe 6 is formed on the upper part of the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com