Propylene butene copolymer foamed beads and preparation method thereof

A technology of foaming beads and butene, which is applied in the field of polymers, can solve the problems of increasing low-molecular random substances, high n-hexane extract, and limiting the application range, etc., and achieves effective expansion of the foaming window, low cost, and high technology Easy to Adjust Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

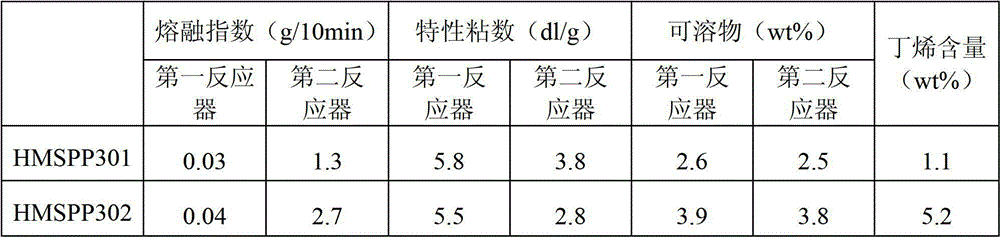

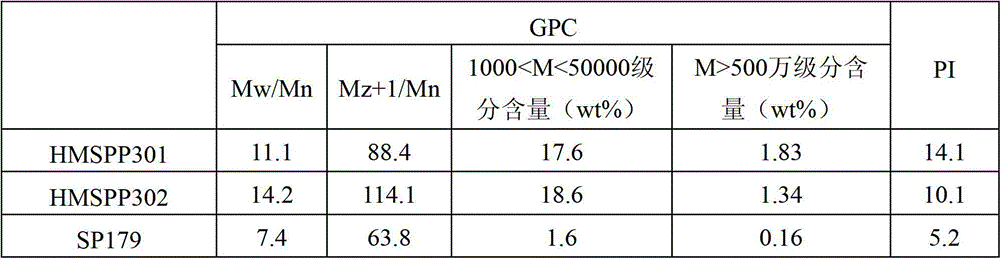

[0032] Preparation of matrix resin HMSPP301

[0033] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor.

[0034] Pre-polymerization reaction: the main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese patent CN93102795, the Ti content is 2.4wt%, the Mg content is 18.0wt%, and the di-n-phthalic acid The butyl ester content is 13 wt%. The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) are pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reactor, the pre-polymerization is carried out in the environment of the propylene liquid phase bulk, the temperature is 15°C, and the residence time is about 4 minutes. Under this...

Embodiment 1~30

[0050] Put 100 parts by weight of high melt strength polypropylene, cell nucleating agent (silicon dioxide or zinc borate) and additives into a high-speed mixer and mix at high speed for 30 seconds, then add LabLine100 microparticle preparation system, and the torque is controlled at about 65% , with a rotating speed of 300 rpm, and pelletizing under water to obtain polypropylene resin particles. Among them, the additives include 0.2 parts by weight of antioxidant 1010 (BASF company) and 0.1 part by weight of antioxidant 168 (BASF company); the amount of cell nucleating agent is shown in Table 5.

[0051] Wherein, the type of polypropylene used in Examples 1-15 is HMSPP301, the type of polypropylene used in Examples 16-30 is HMSPP302; the cell composition used in Examples 1-4, 9-12, 16-19 and 24-27 The nucleating agent is silicon dioxide, and the cell nucleating agent used in Examples 5-8, 13-15, 20-23 and 28-30 is zinc borate.

[0052] Use deionized water as the dispersion m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com