Control system for blowing of copper converter

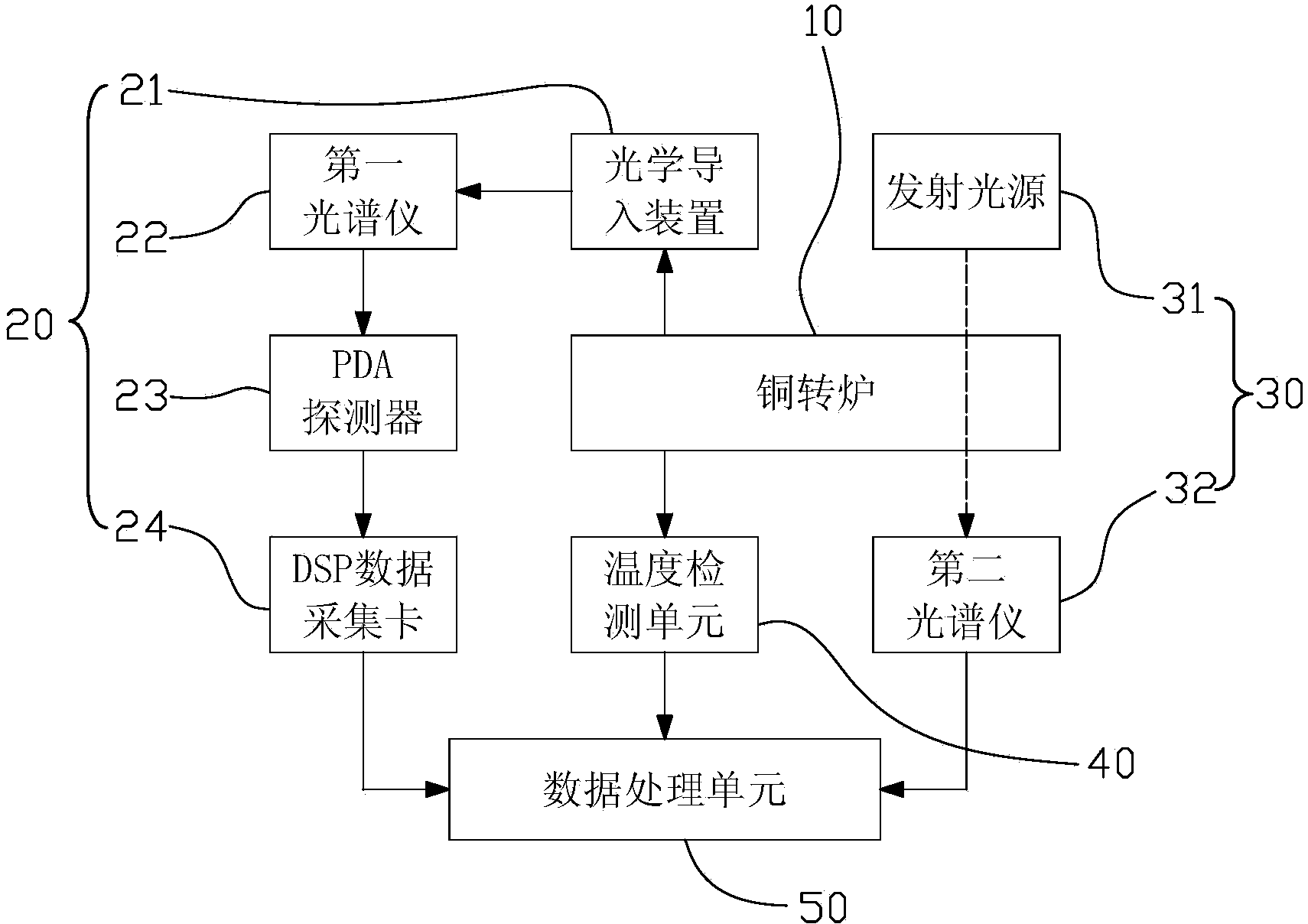

A converter blowing and control system technology, applied in the field of copper concentrate smelting, can solve problems such as air pollution, inaccurate judgment of the end point, frequent tilting of the furnace body, etc., and achieve the effect of ensuring safe production and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

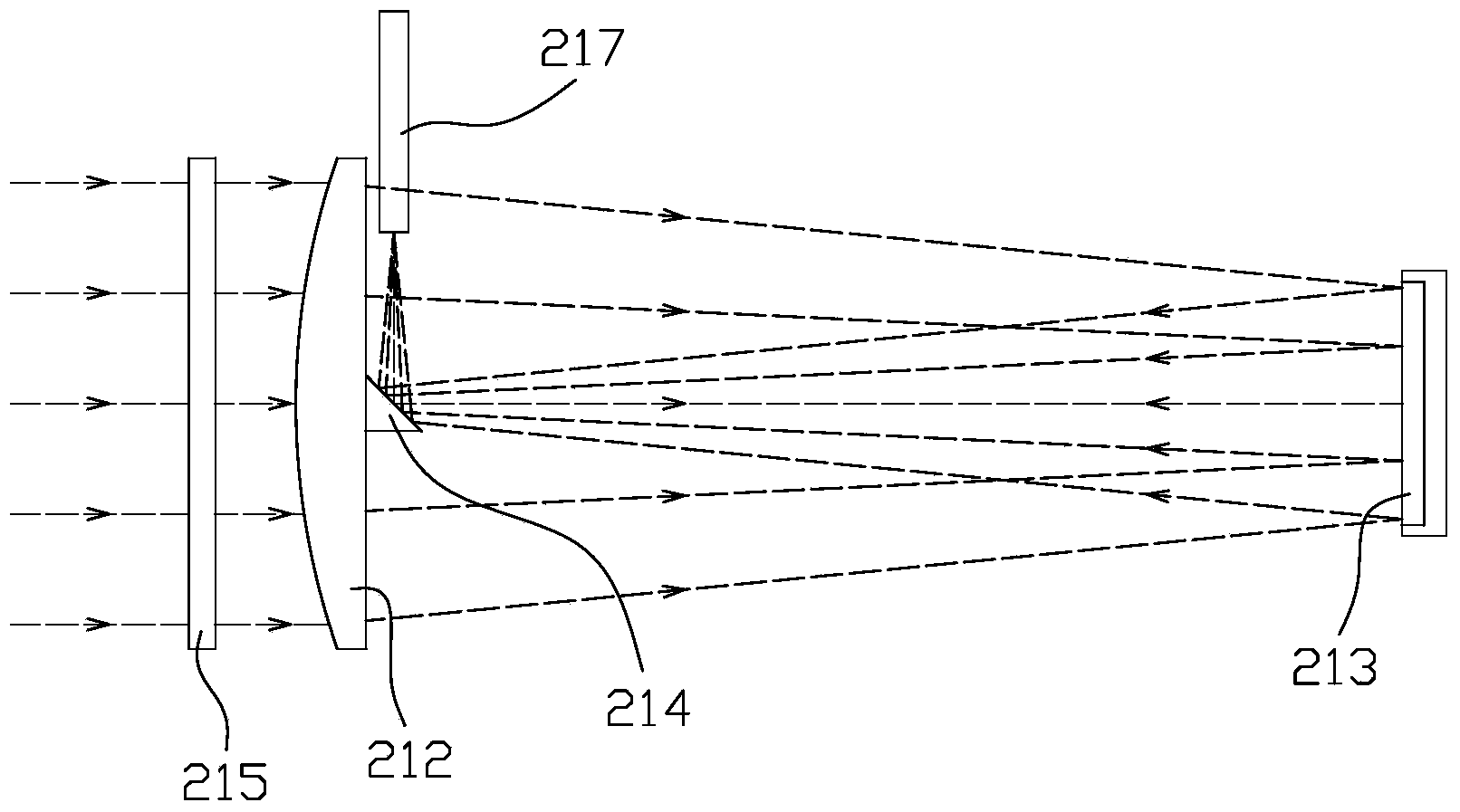

[0030] In the first embodiment, the mirror 214 is bonded to the lens 212 and arranged on a side close to the plane mirror 213, and the centers of the lens 212, the plane mirror 213 and the mirror 214 are located on the same straight line, and the optical path diagram is as follows figure 1 shown. When the reflector 214 is arranged on one side of the lens 212 instead of the peripheral position, the reflector 214 can block the incident light to a certain extent, but because the size of the reflector 214 is very small, the light blocked by it is very little and can be ignored; When this optical path is adopted for design, the structure of the lens barrel 211 is simple, and the arrangement of the optical fiber 217 is more convenient.

Embodiment 2

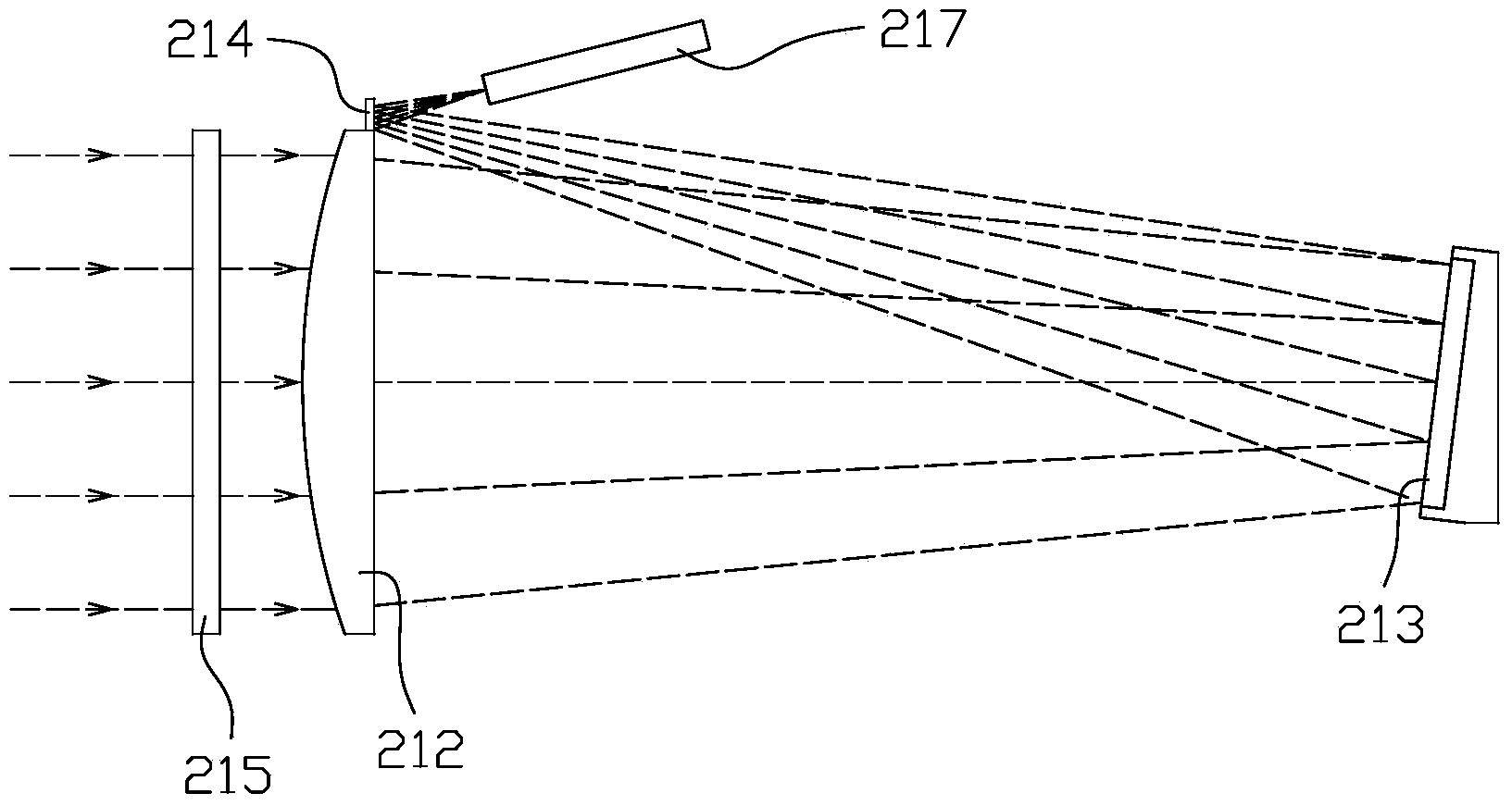

[0031] In the second embodiment, the reflector 214 is located adjacent to the periphery of the lens 212, and the plane reflector 213 forms a certain angle with the axis of the lens barrel 211, and the angle makes the plane reflector 213 emit light To the reflector 214, the light path diagram is as follows figure 2 shown. When using this optical path design, since the oblique line is longer than the straight line, the lens barrel 211 can be further shortened, and the mirror 214 is arranged around the lens 212, which will not block the incident light. Therefore, the structure of the lens barrel 211 and the arrangement of the optical fiber 217 are more complicated than those in the first embodiment.

[0032] refer to Figure 4 , Figure 5 , Figure 6 , in comparison, the arrangement of the optical fiber 217 and the structure of the lens barrel 211 are simpler and easier to design by adopting the scheme in the first embodiment. The following will describe in detail by taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com